Adjustable short-circuit release

A release and overcurrent technology, applied in the direction of adjusting the conditions of protection switches, circuits, and parts of protection switches, etc., can solve problems such as unfavorable friction and large force tolerance, and achieve the effect of preventing loosening or unscrewing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

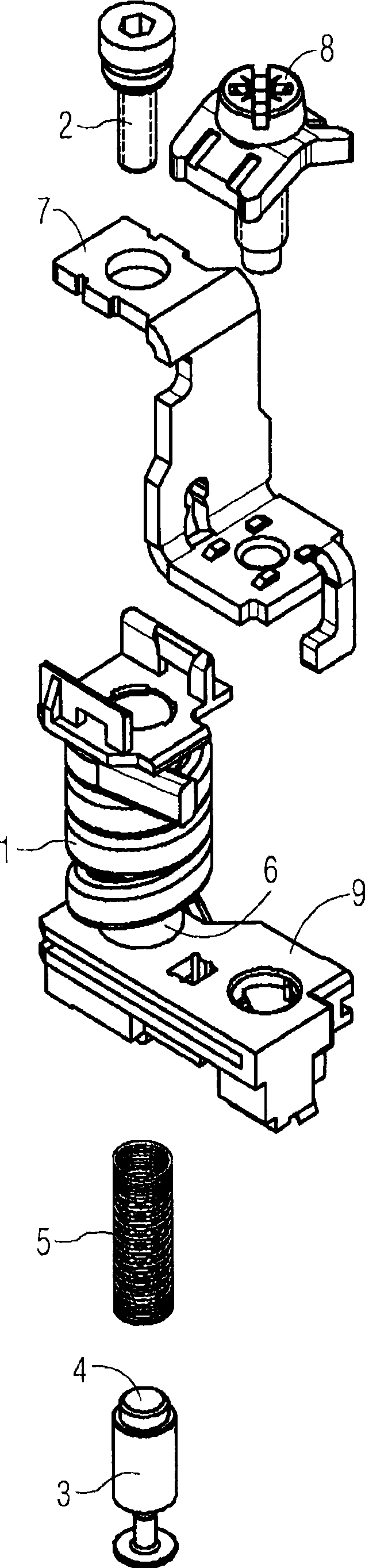

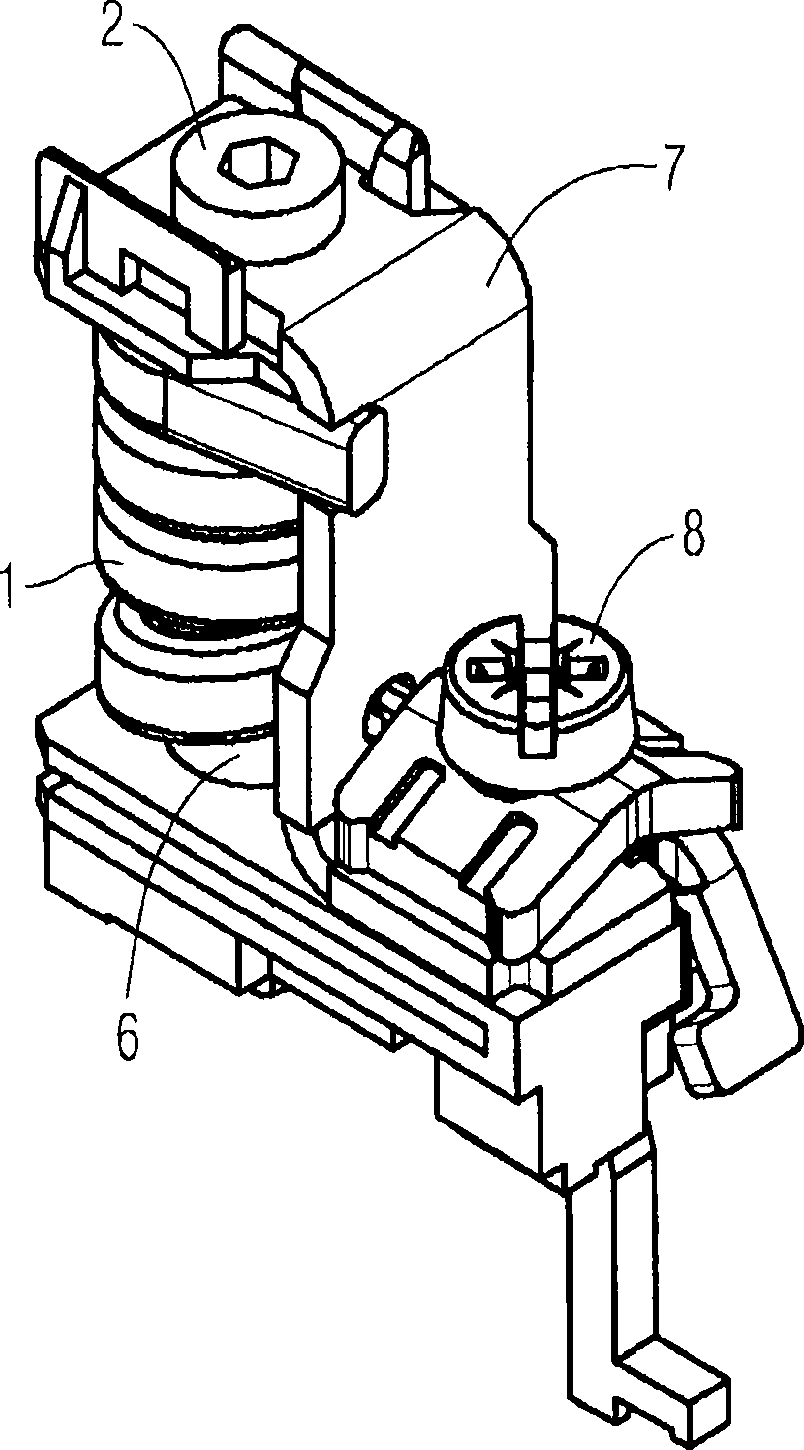

[0018] figure 1 An exploded view showing the main components of an overcurrent release for a power switch for switching and protecting motors and other consumers. The overcurrent release here comprises a coil winding 1 on a coil former 6 , a pole 2 , an armature 3 , a compression spring 5 and a connecting piece 7 . The coil former 6 is formed in one piece with the carrier element 9 . The substantially Z-shaped yoke is formed in one piece and corresponds to the connection part 7 . Furthermore, the combination bolt 8 serves to position the two parts 7 and 9 relative to each other. In the assembled state, the compression spring 5 is located within the coil former 6 between the pole 2 and the armature 3 . On the side facing the compression spring 5 , the armature 3 has a projection 4 corresponding to the inner diameter of the compression spring 5 , which is surrounded by the compression spring 5 in the assembled state. The electrode 2 can be fixed on the connecting piece 7 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com