Argon-nitre adipate gas recovery system

A technology for waste gas recovery and adipic acid, which is applied in the field of adipic acid argon nitrate waste gas recovery system, which can solve the problems of incompleteness, unsatisfactory argon nitrate gas washing effect, waste of water, electricity and sewage treatment costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

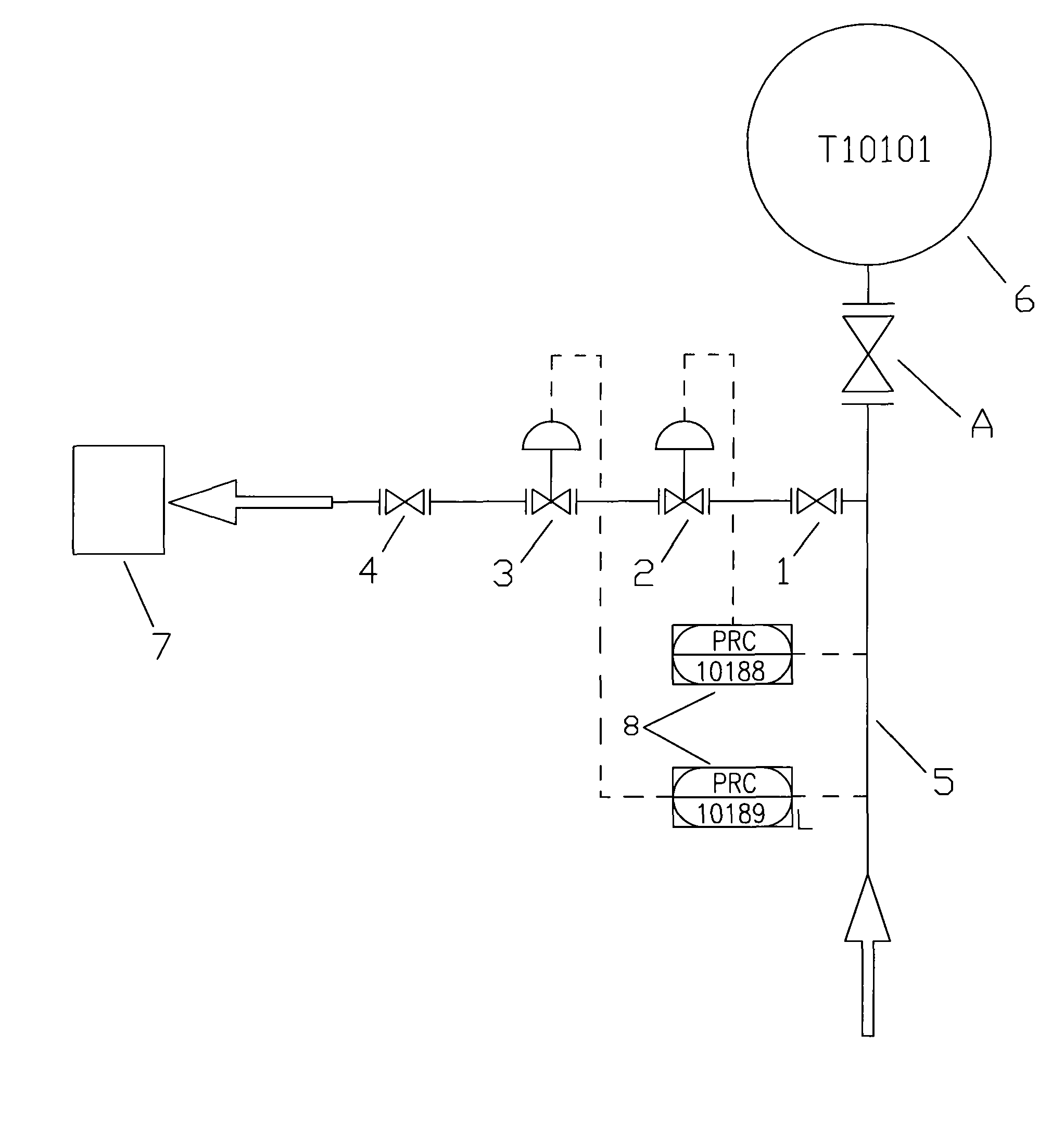

[0019] Accompanying drawing is a kind of specific embodiment of the present invention.

[0020] The adipic acid argon nitrate waste gas recovery system of the present invention includes a gate valve A installed on the argon nitrate waste gas header 5 near the washing tower 6, and an outlet pipe installed on the argon nitrate waste gas header before the gate valve A , the output end of the lead-out pipe is connected to the inlet of the argon and nitrate gas compressor 7, and the middle part of the lead-out pipe is installed with a pressure regulating valve 2 and a low-pressure cut-off valve 3 connected in series, and two pressure transmitters for controlling the pressure regulating valve 2 and the low-pressure cut-off valve 3 The pressure point of 8 is located at different positions in front of the outlet pipe on the argon nitrate waste gas header. A gate valve 1 and 4 are respectively installed at both ends of the outlet pipe, and they are connected in series with the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com