Device and technology for continuous production of sodium fluosilicate

A technology for sodium fluorosilicate and fluorosilicic acid, which is applied in the field of devices for continuous production of sodium fluorosilicate, can solve the problems of aggravated dilute acid system scaling, low utilization rate of fluorosilicic acid and sodium sulfate, and unreusable mother liquor. , to achieve the effect of alleviating scaling, saving primary water, and improving the utilization rate of Na+

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

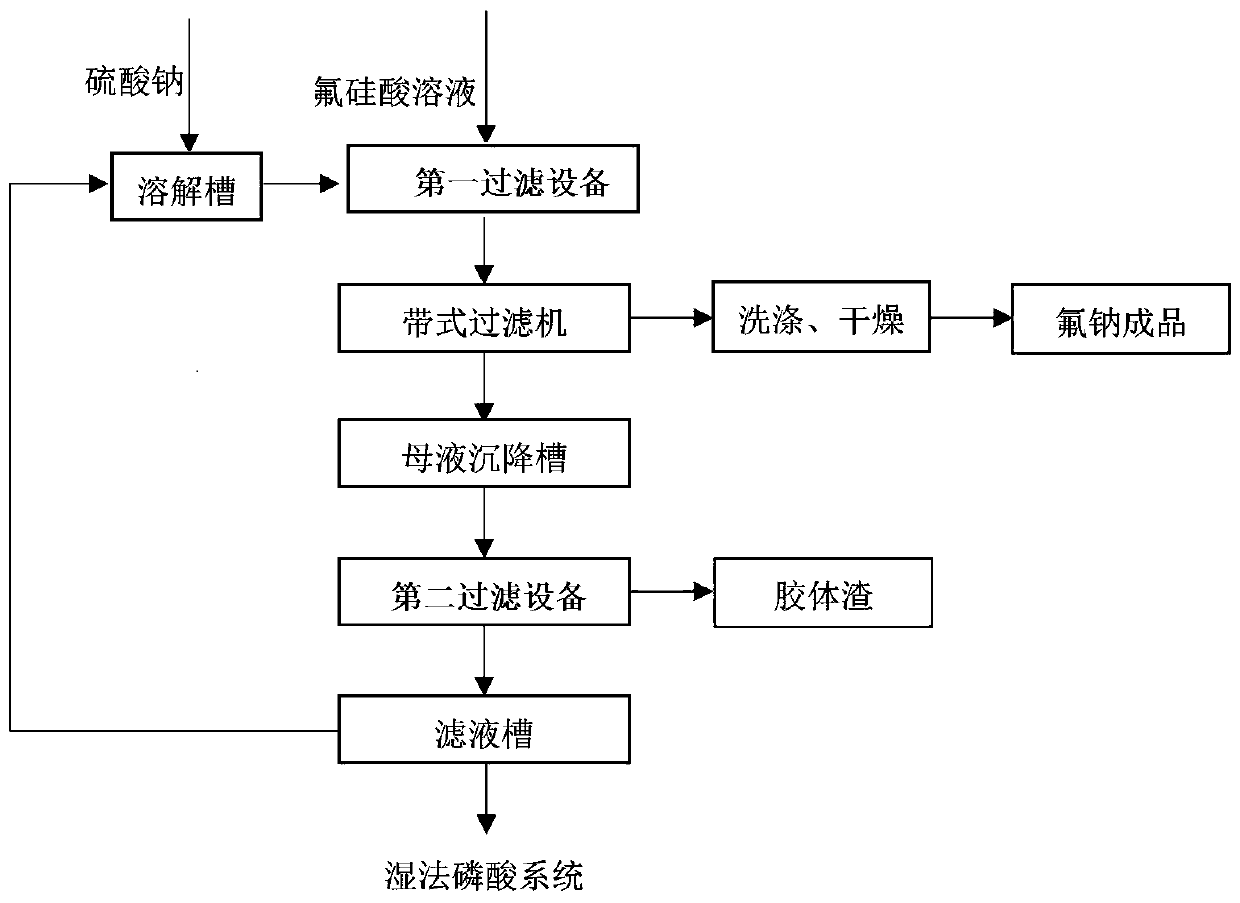

[0024] A process for continuous production of sodium fluorosilicate, the process of which is as follows figure 1 shown.

[0025] Use a screw feeder to add 98% industrial grade sodium sulfate at a feed rate of 50kg / h to the dissolution tank, and mix it with the filtrate transported from the filtrate tank. The filtrate flow rate is 320kg / h; the temperature is controlled at 45°C and mixed evenly The final solution is sent to the mixing tank.

[0026] Add 18% fluosilicic acid solution to the mixing tank, the flow rate is 300kg / h, react at room temperature for 1min, transport the reaction slurry to a vacuum belt filter, and obtain a 61kg / h finished product after filtering, washing and drying Sodium fluorosilicate, the purity of the finished sodium fluorosilicate is more than 99%. The filtered mother liquor is sent to the mother liquor settling tank. After settling for 5 hours, it is sent to the filter press for pressure filtration. Part of the filtrate separated from the colloidal...

Embodiment 2

[0028] Use a screw feeder to add 98% industrial grade sodium sulfate at a feed rate of 50kg / h to the dissolution tank, and mix it with the filtrate transported from the filtrate tank. The filtrate flow rate is 320kg / h; the temperature is controlled at 45°C and mixed evenly The final solution is sent to the mixing tank.

[0029] Add 18% fluosilicic acid solution to the mixing tank, the flow rate is 310kg / h, react at room temperature for 1min, transport the reaction slurry to a vacuum belt filter, and obtain a 60kg / h finished product after filtering, washing and drying Sodium fluorosilicate, the purity of the finished sodium fluorosilicate is more than 99%. The filtered mother liquor is sent to the mother liquor settling tank. After settling for 5 hours, it is sent to the filter press for pressure filtration. Part of the filtrate separated from the colloidal slag is returned to the dissolution tank to dissolve sulfuric acid. Sodium, the other part is sent to the phosphoric acid ...

Embodiment 3

[0031] Use a screw feeder to add 98% industrial grade sodium sulfate at a feed rate of 50kg / h to the dissolution tank, and mix it with the filtrate transported from the filtrate tank. The filtrate flow rate is 320kg / h; the temperature is controlled at 45°C and mixed evenly The final solution is sent to the mixing tank.

[0032] Add 20% fluosilicic acid solution to the mixing tank, the flow rate is 300kg / h, react at room temperature for 3min, transfer the reaction slurry to a vacuum belt filter, and obtain a 65kg / h finished product after filtering, washing and drying Sodium fluorosilicate, the purity of the finished sodium fluorosilicate is more than 99%. The filtered mother liquor is sent to the mother liquor settling tank. After settling for 5 hours, it is sent to the filter press for pressure filtration. Part of the filtrate separated from the colloidal slag is returned to the dissolution tank to dissolve sulfuric acid. Sodium, the other part is sent to the phosphoric acid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com