Horizontal transport mechanism for self-propelled carriages

A transport mechanism and horizontal technology, which is applied to elevated railway systems with suspended vehicles, railway systems with propulsion equipment, locomotives, etc., and can solve problems such as excessive curvature radius, system enlargement, and inability to install transport systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

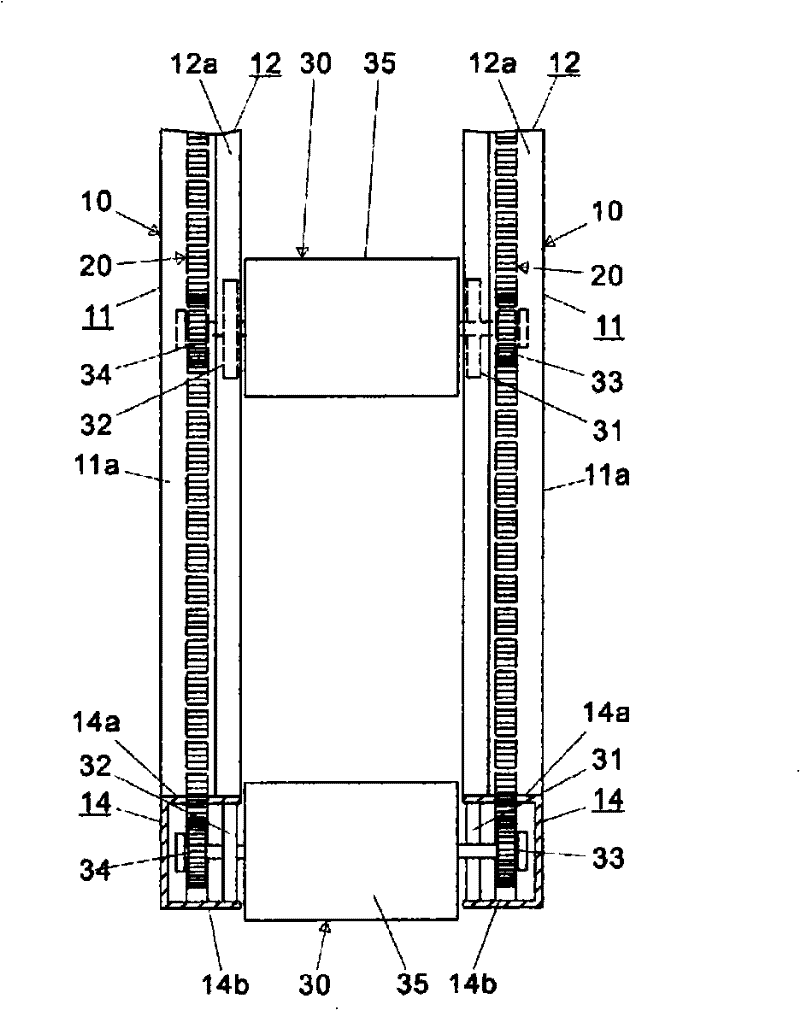

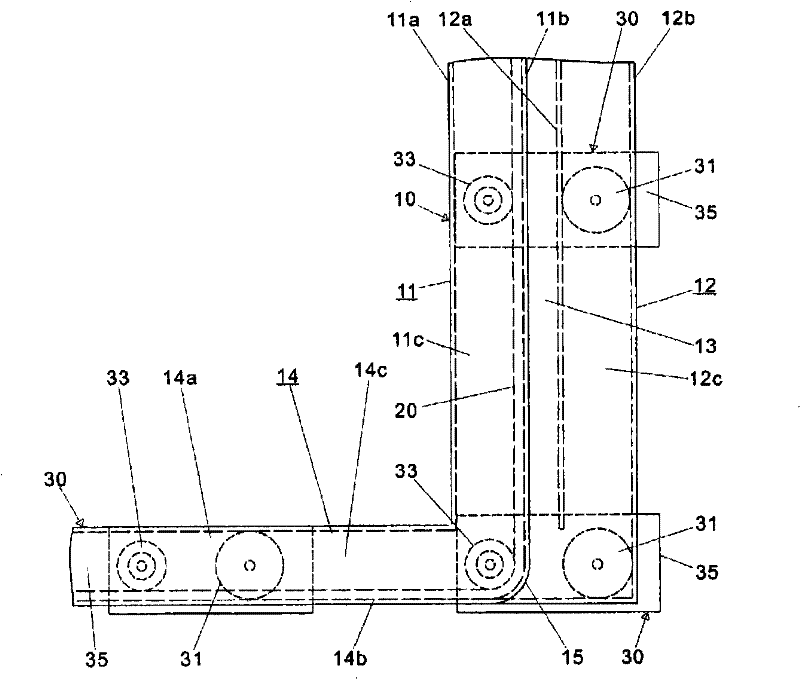

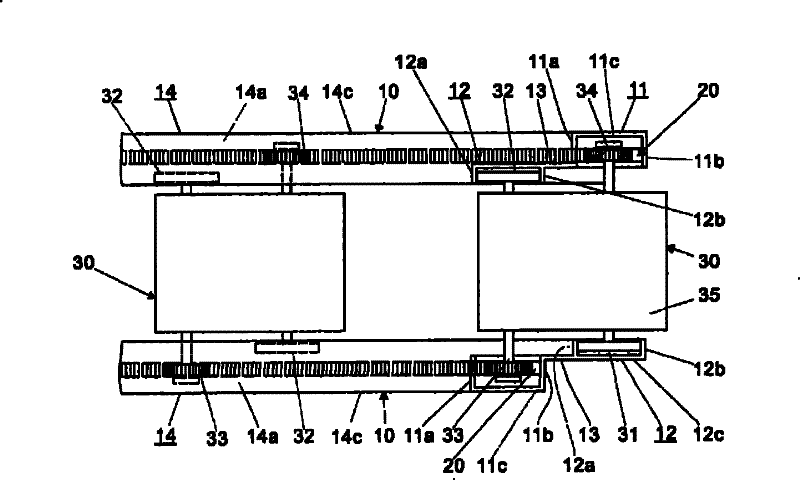

[0024] The embodiment of the horizontal conveying mechanism of the self-propelled vehicle frame of the present invention will be described below with reference to the accompanying drawings. In the attached picture, figure 1 It is a front view showing an embodiment of the horizontal transport mechanism of the self-propelled vehicle frame according to the first structure of the present invention, figure 2 yes figure 1 Right side view of the horizontal transport mechanism shown, image 3 yes figure 2 top view of Figure 4 yes Figures 1 to 3 A perspective view of the horizontal transport mechanism of the first structure shown, Figure 5 It is a front view showing an embodiment of the horizontal transport mechanism of the self-propelled vehicle frame according to the second structure of the present invention, Figure 6 yes Figure 5 Right side view of the horizontal transport mechanism shown, Figure 7 yes Figure 6 top view of Figure 8 yes Figures 5 to 7 A perspect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com