Floor structure of scooter type vehicle

A technology for motorcycles and floors, used in motor vehicles, pedals, bicycles, etc., can solve the problems of reducing the number of parts, reducing the degree of freedom of design, and increasing the number of parts, so as to reduce the number of parts and improve the freedom of design. degree, improve the overall effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

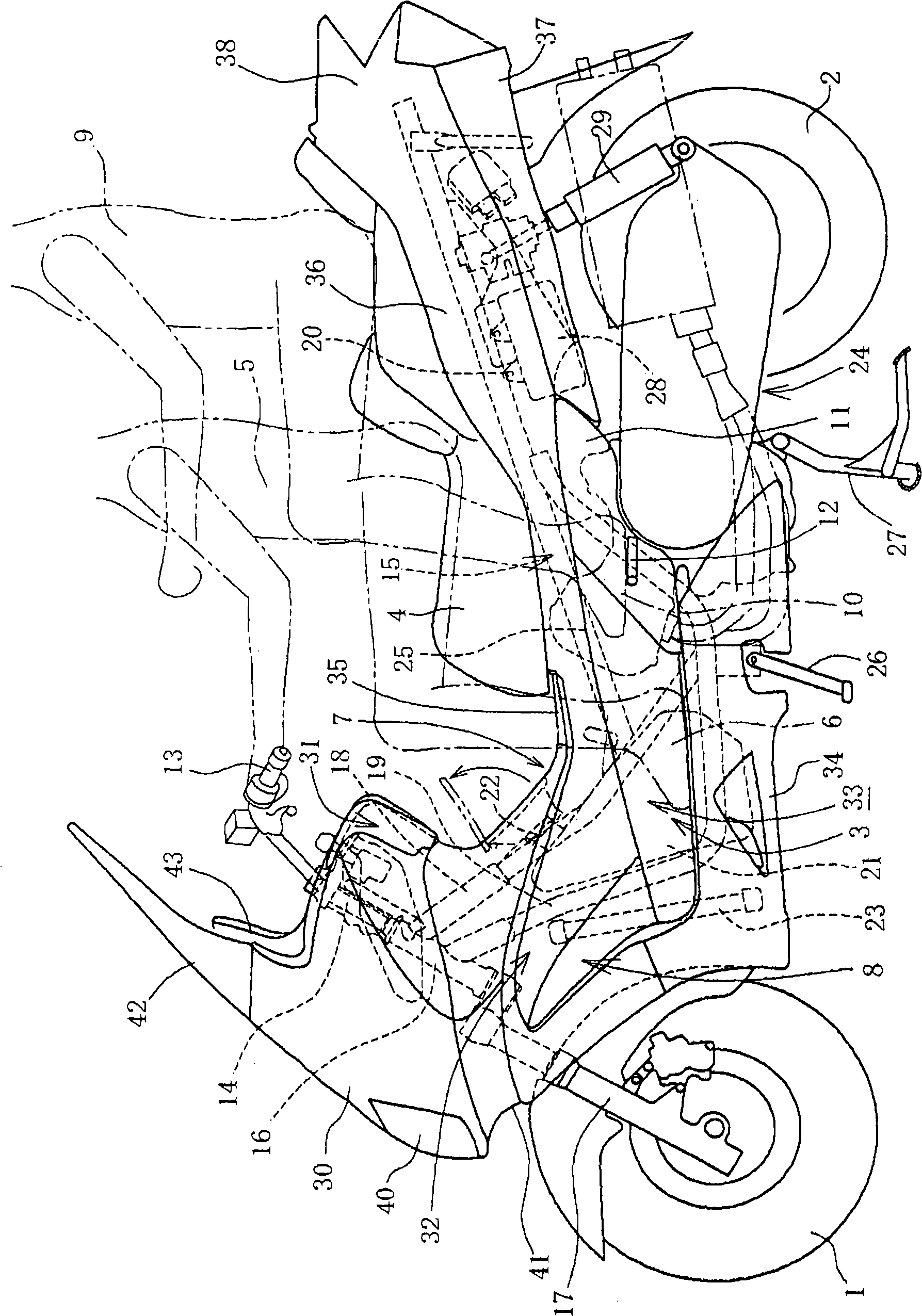

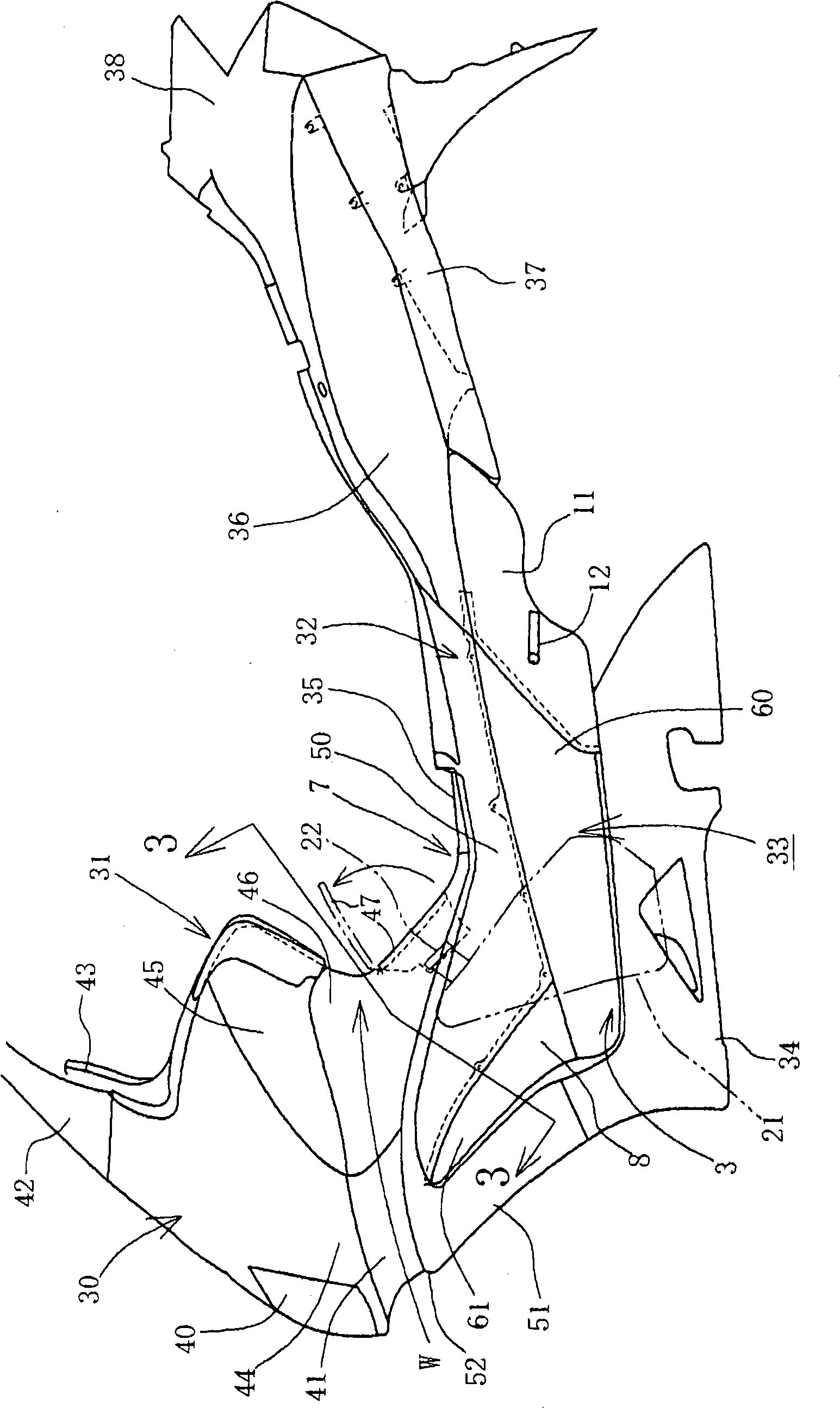

[0030] Next, an embodiment will be described with reference to the drawings. figure 1 It is a side view of a scooter-type motorcycle to which the present invention is applied. This vehicle is equipped with a low-floor tread floor 3 between the front wheel 1 and the rear wheel 2, and the vehicle seat 4 is disposed above the rear end of the tread floor 3, and the driver 5 sitting on the seat 4 The foot 6 steps on the pedal floor 3 .

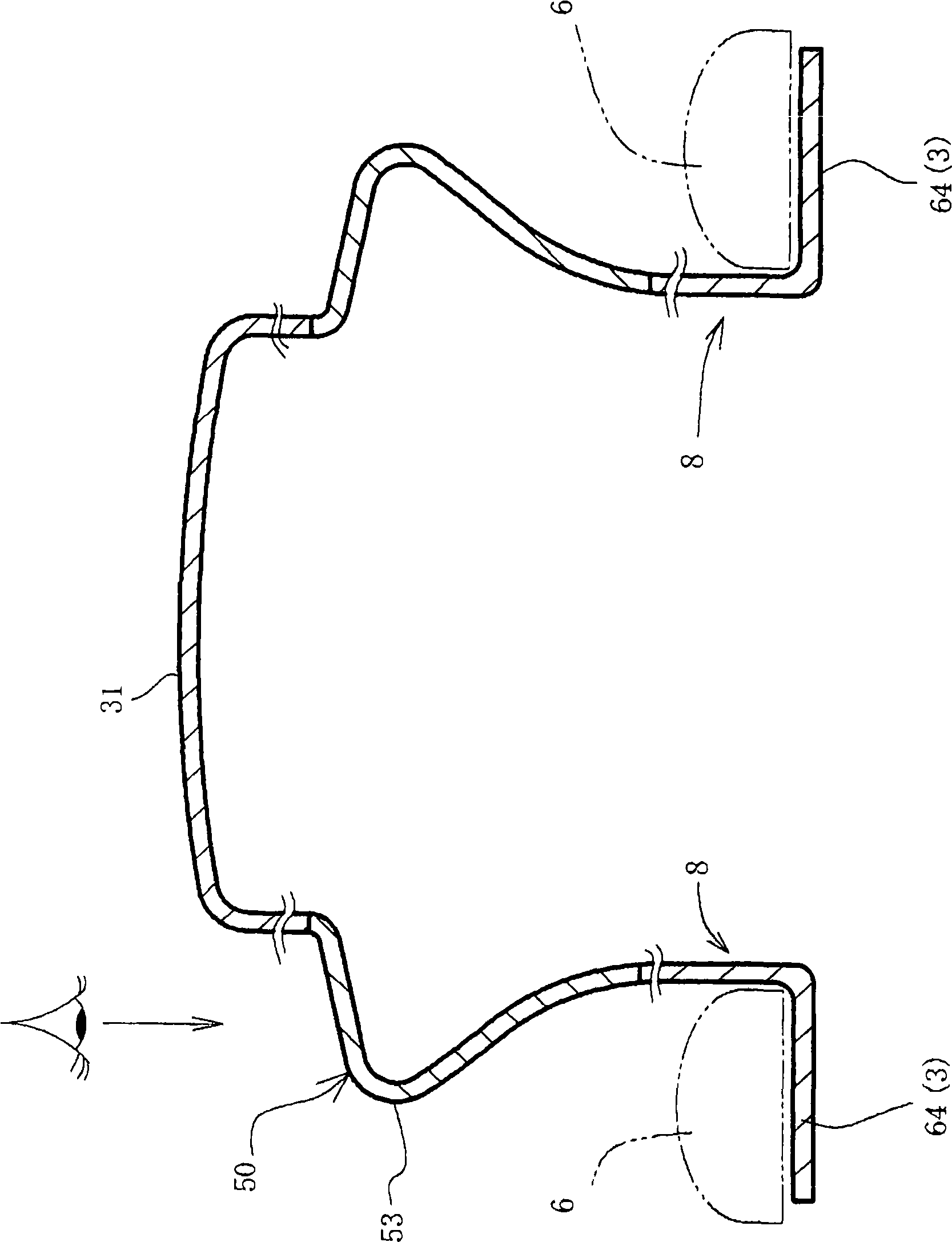

[0031] The footrest floor 3 is provided on the left and right with the central tunnel-like portion 7 interposed therebetween. On the front side of the step floor 3, a leg cover 8 covering the front of the feet 6 is provided. The tunnel-like portion 7 is a part of the body cover raised along the center of the vehicle body, and the inside is hollow. The vehicle seat 4 is a front and rear seat type, and the pin 10 of the passenger 9 steps on the back seat pedal 12, and the rear seat pedal 12 is located on the pedal support 11.

[0032] The handle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com