Uniform illuminating device

A technology of uniform light emission and light-emitting surface, applied in the direction of lighting devices, lighting device parts, light sources, etc., can solve the problems such as vignetting of the light-emitting cover, affecting the heat dissipation of light-emitting diodes, affecting the system effect, etc., to achieve high utilization of light energy, Avoid halo or flare phenomenon, uniform light receiving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

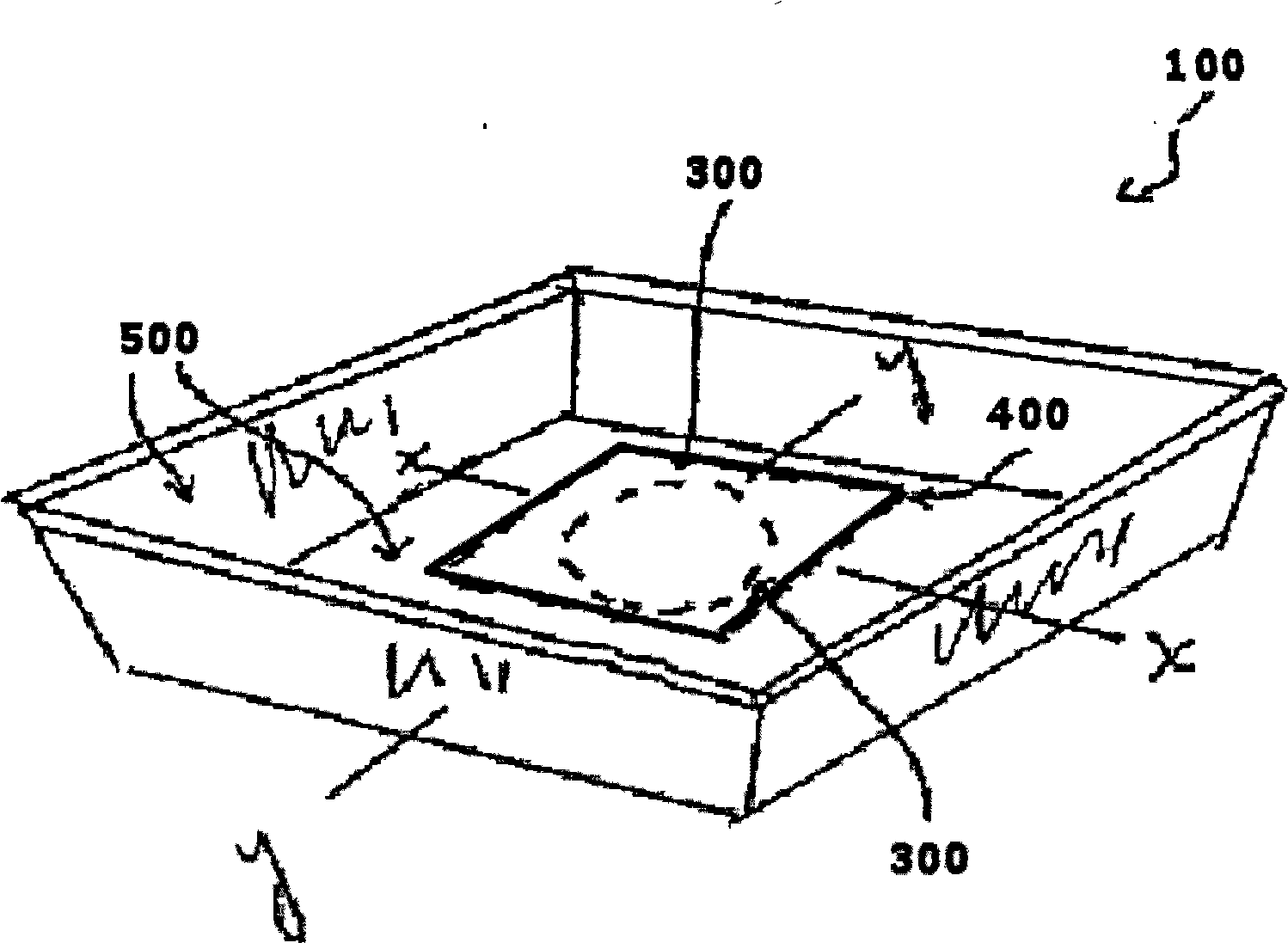

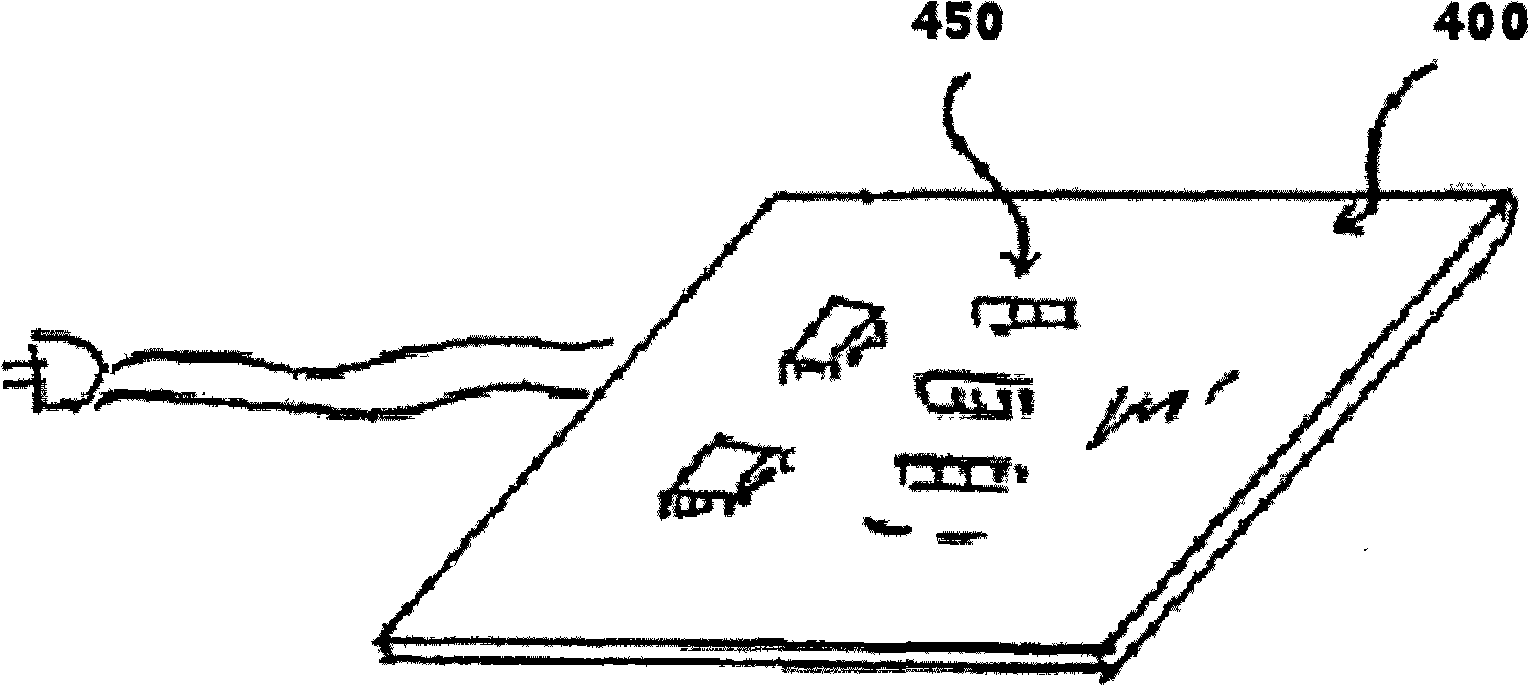

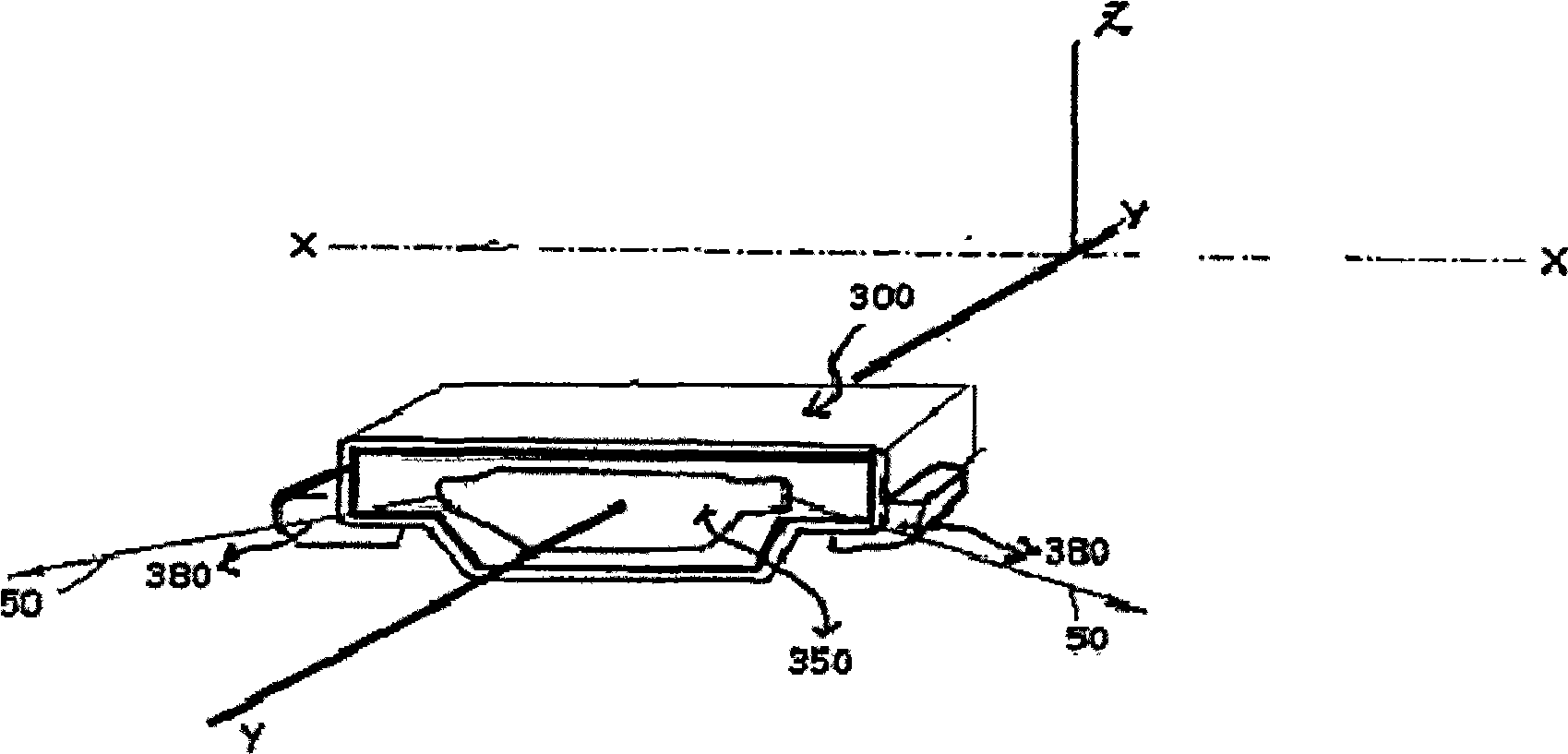

[0040] The experimental structure is the same as figure 1 As shown, 12 single-sided light emitting diodes 300 (each with a power of 0.125 watts, using the SWTS1007 series products of Seoul Semiconductor Corporation) are welded on a circuit board 400 to form a circular circle with a diameter of 30 mm. All the light-emitting surfaces 350 of the light-emitting diodes 300 face the reflector 500, and the reflector 500 is made of foamed polyethylene terephthalate of Furukawa Corporation. The current applied to the circuit board 400 was 0.135 amperes. The internal size of the reflector 500 is 900mm×900mm.

[0041] Placed on the reflector 500 is a diffuse transmissive translucent screen 68, which is model #432 of Shinkolite-A series from Mitsubishi Rayon Co. Ltd., with a thickness of 3mm and made of acrylic resin. The distance 62 between the light-transmitting screen 68 and the circuit board 400 is measured to be 35 mm.

[0042] The brightness on the translucent screen 68 is measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com