Method for improving metallurgy solution crystallization deposition in air cooling course and air cooling column

A technology of solution crystallization and air cooling tower, which is applied in the direction of electrolysis process, water shower cooler, lighting and heating equipment, etc., can solve the problems of crystal deposition and other problems, achieve the effect of improving crystal deposition, improving operating efficiency and reducing the loss of main components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

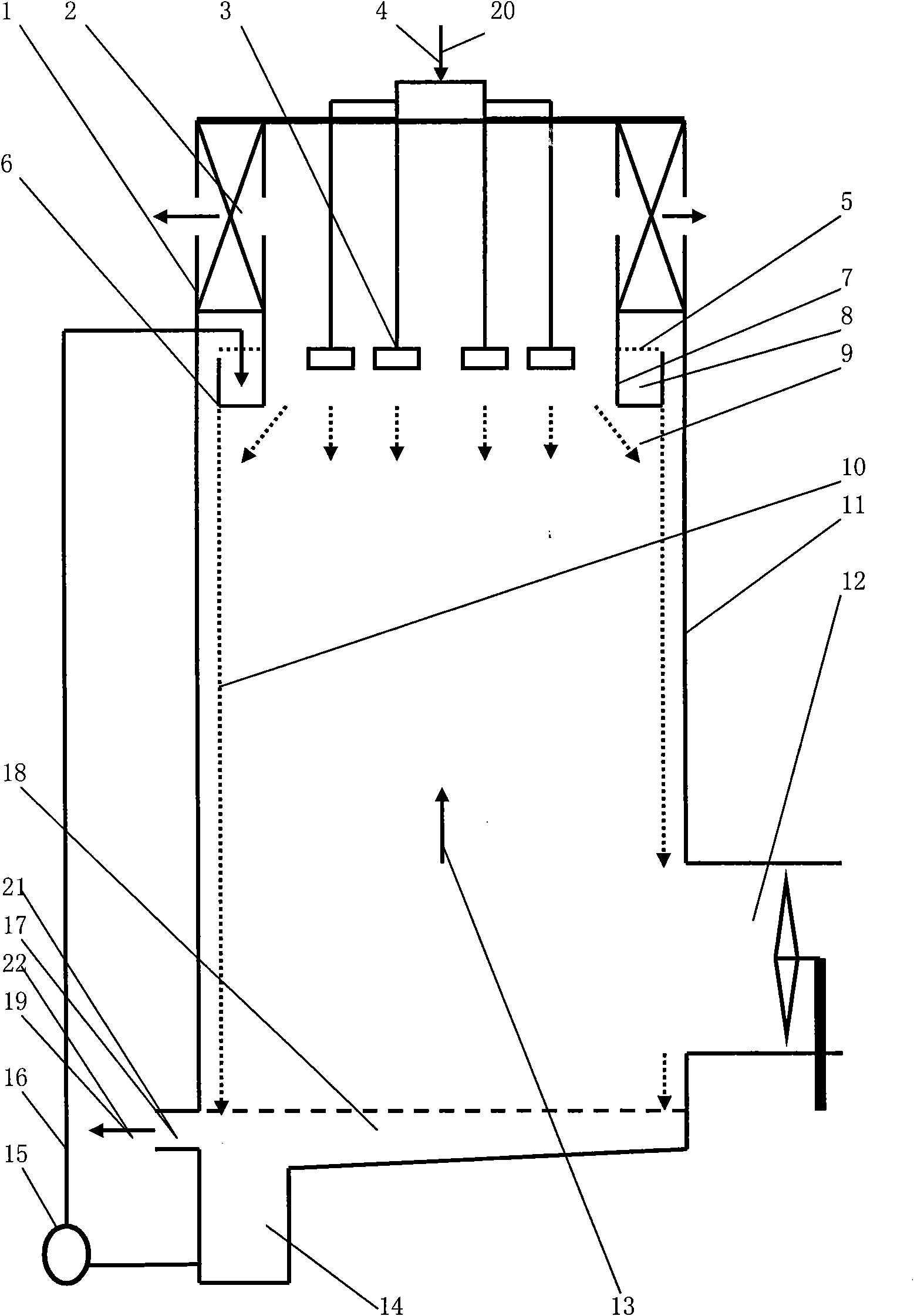

[0021] by figure 1 It can be seen that the present invention is a method for improving the deposition of metallurgical solution crystals in the air cooling process. The described method is to use the metallurgical solution after cooling the air cooling tower to be transported to the upper part of the air cooling tower by a conveying device, and then flow down through the inner wall surface of the tower barrel to form a liquid flow film covering the inner wall surface of the tower barrel to spray The cooling liquid droplets that reach the inner wall of the tower barrel cannot directly fall on the surface of the tower itself, but fall into the liquid flow film on the inner wall surface of the tower barrel, thereby preventing the droplet crystals from depositing on the inner wall of the tower barrel; at the same time, it can also cool the tower. The cooled metallurgical solution is irradiated with ultrasonic waves to refine the crystal grains in the air-cooled metallurgical solutio...

Embodiment 2

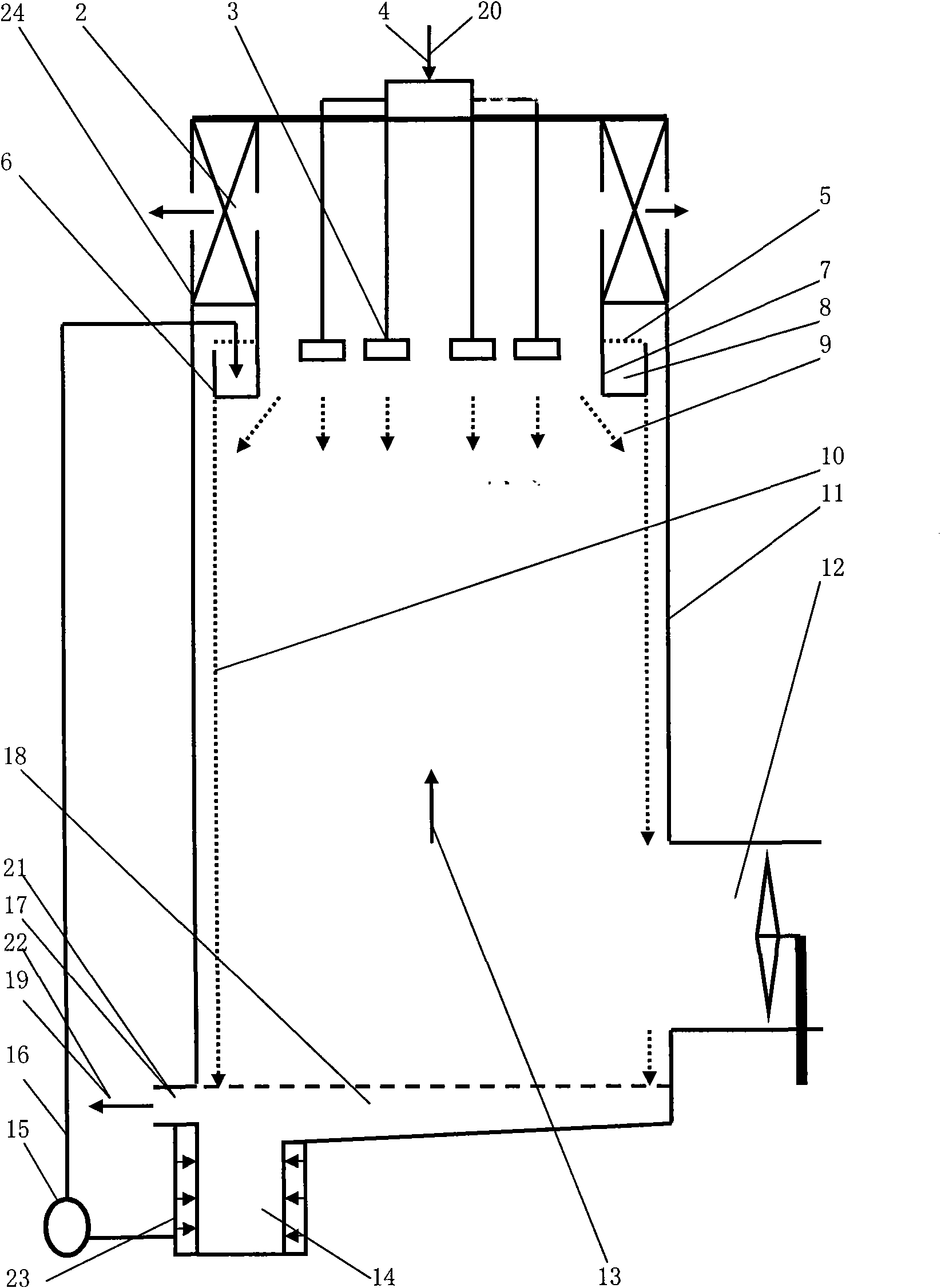

[0025] figure 2 This is another embodiment of the present invention. From figure 2 It can be seen that this is an ultrasonic air cooling tower 24 that improves the crystal deposition of metallurgical solution in the air cooling process. The ultrasonic air-cooling tower 24 includes a tower barrel 11, a tower tank 18, a spray device 3, a drip catching device 2, an air blowing device 12, and a liquid flow film forming device 6. The liquid flow film forming device 6 includes ultrasonic Wave source device 23. The principle of the second embodiment is the same as that of the first embodiment, except that the metallurgical solution 19 after air cooling has a frequency of 15-128kHz and a sound intensity of 0.5-50w / cm 2 After direct or isolated irradiation of the ultrasonic wave, it is transported to the circumferential liquid distribution device 7 by the conveying device 15 through the pipeline 16, and then uniformly distributed to the inner wall surface of the tower 11 by the circ...

Embodiment 3

[0027] figure 1 It is another embodiment of the present invention. The principle of the third embodiment is the same as that of the first embodiment, except that the metallurgical solution 4 becomes zinc sulfate solution 20, and the metallurgical solution outlet 17 after air cooling becomes zinc sulfate after air cooling. At the solution outlet 21, the air-cooled metallurgical solution 19 becomes the air-cooled zinc sulfate solution 22. The zinc sulfate solution air cooling tower is used in the wet zinc metallurgical production process, and can greatly improve the crystal deposition of the zinc sulfate solution 20 on the inner wall surface of the tower 11 during the air cooling process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com