Patents

Literature

36results about How to "Reduce the amount of maintenance work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

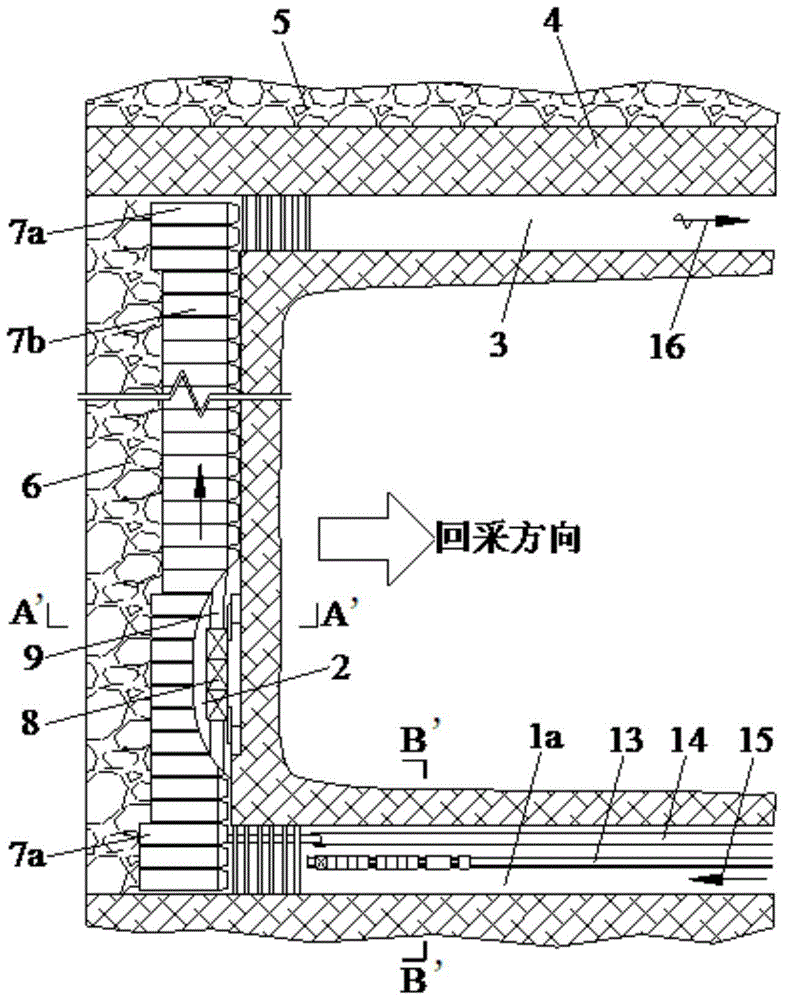

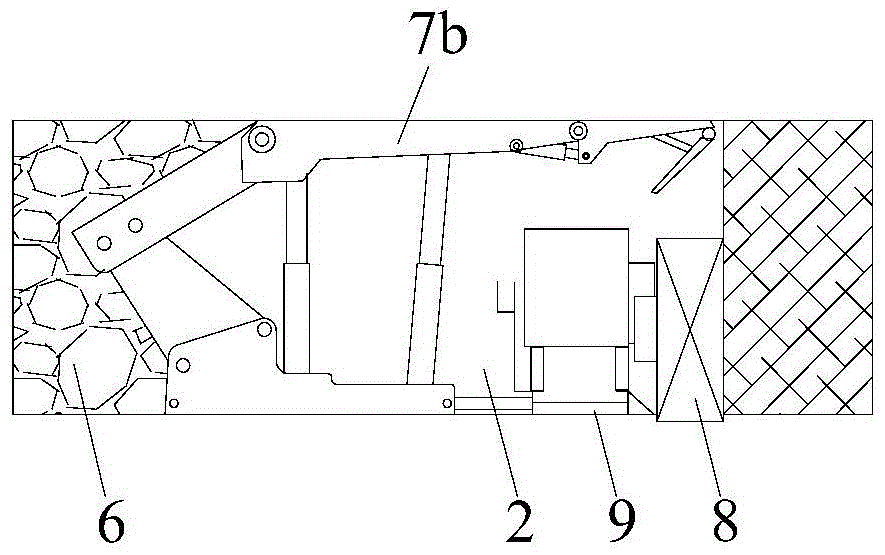

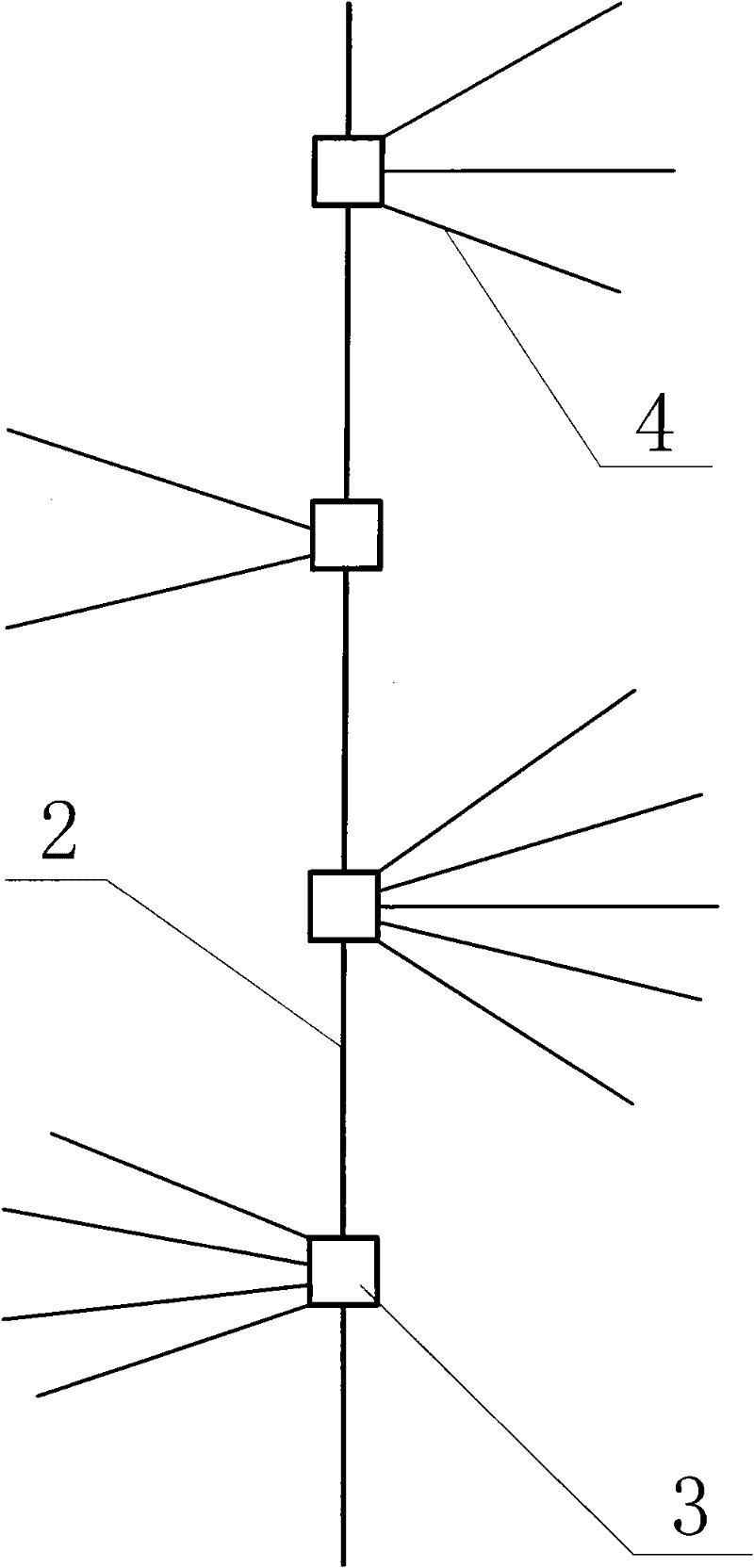

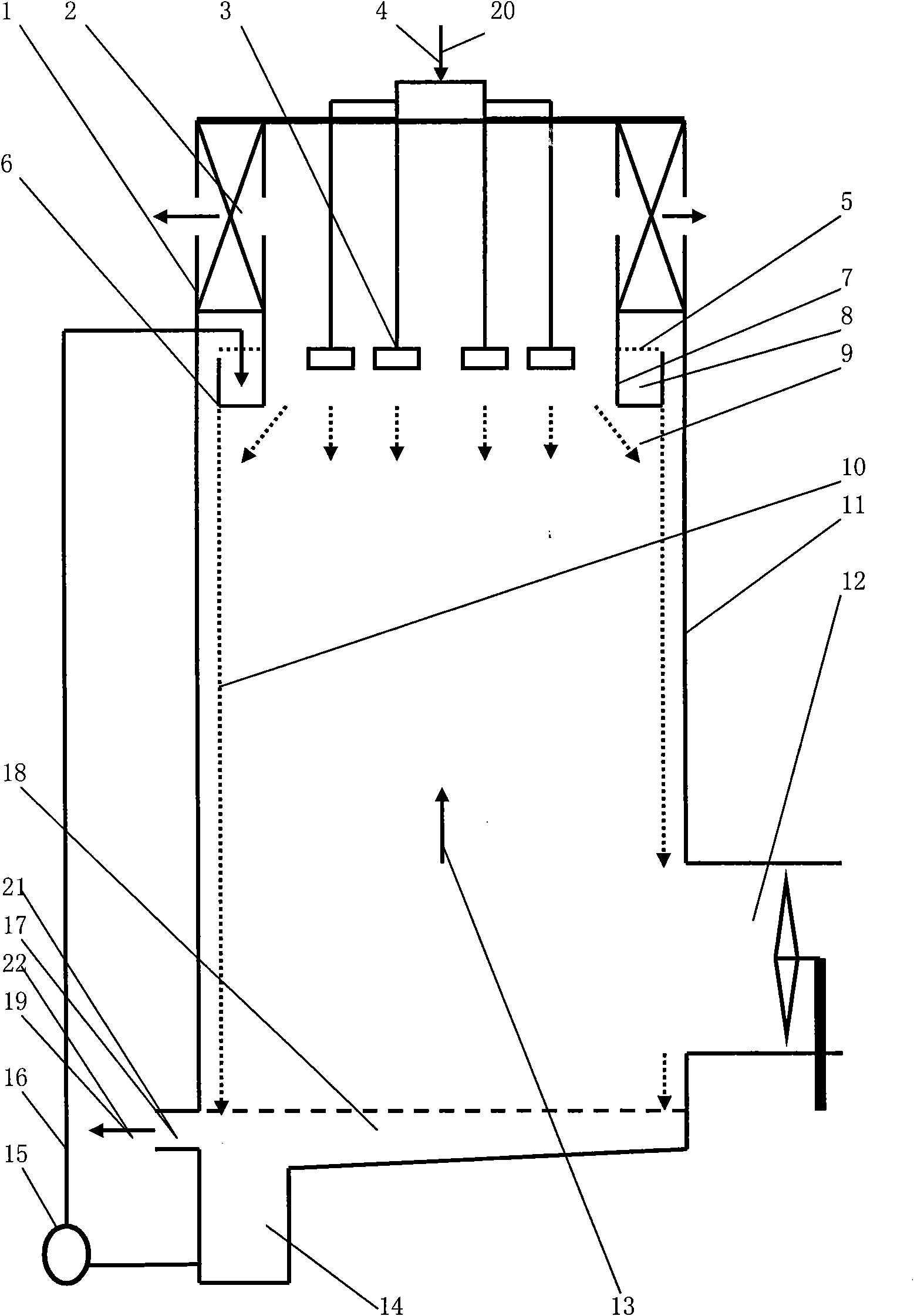

Z-shaped ventilation method and system for gob-side entry of coalface

InactiveCN104179520AReduced roadway excavation and maintenance worksReduce manufacturing costTunnel/mines ventillationCoal pillarCoal

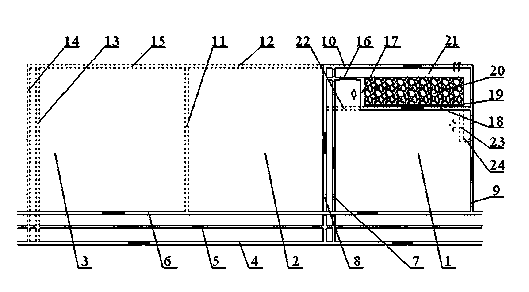

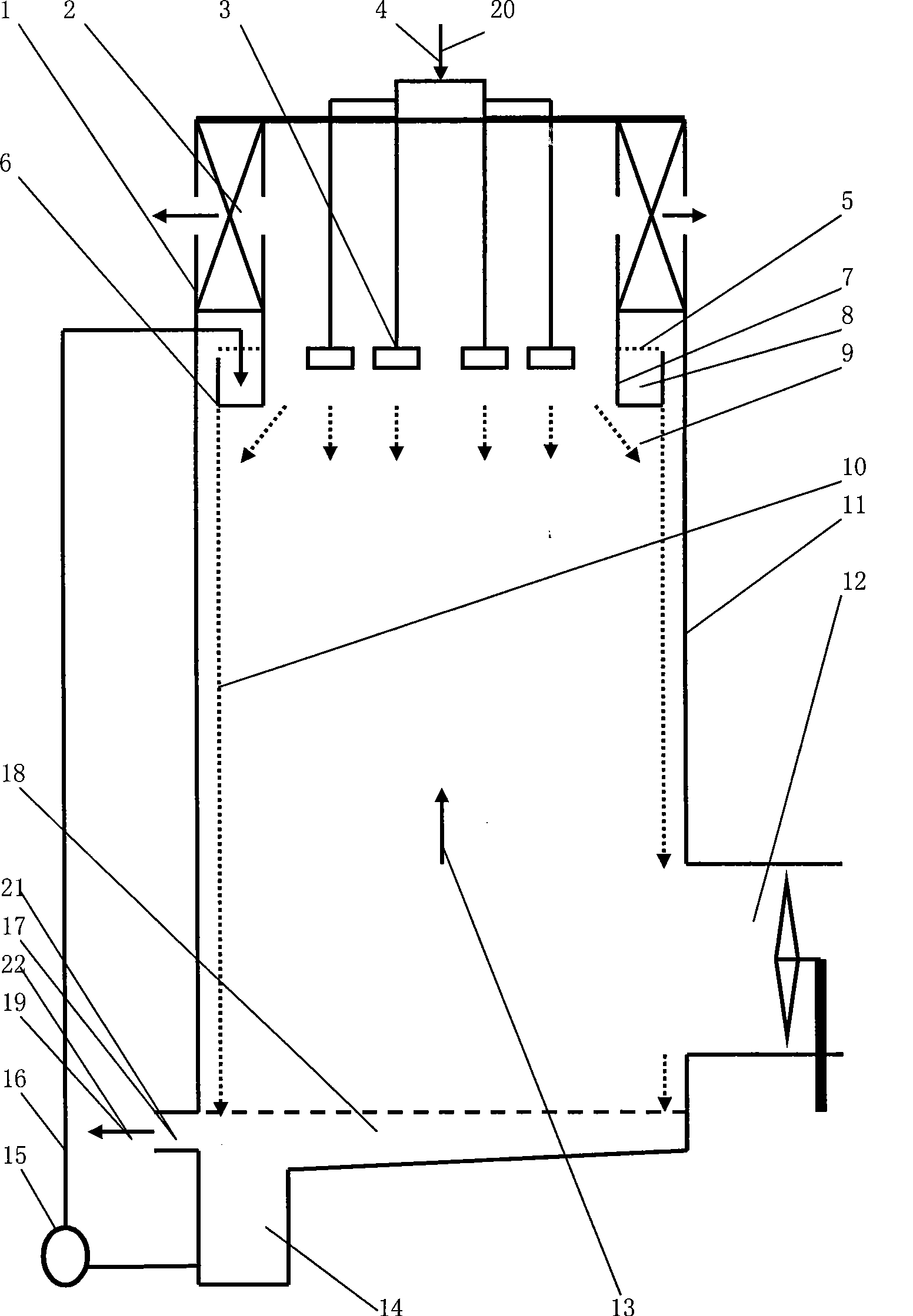

The invention relates to a Z-shaped ventilation method and system for a gob-side entry of a coalface. An air inlet way and an air return way of the coalface are arranged on the front side and the rear side of the coalface respectively, and the coalface is disposed by 90 degrees to form the Z-shaped ventilation system of the coalface. The air return way of the coalface is reserved by adopting pier stud materials, flexible die or high-water materials in a gob-side entry manner, after extraction of a last coalface is finished, the air return way can be reused as a part of the air inlet way, coal pillars for separating the two adjacent coalfaces are omitted, and railways or air return ways in mining areas which are adjacently arranged are reused. By the Z-shaped ventilation method and system, roadway tunneling during arrangement of the coalfaces is effectively reduced, coal recovery rate is increased, and high output and efficiency of coals are realized.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV

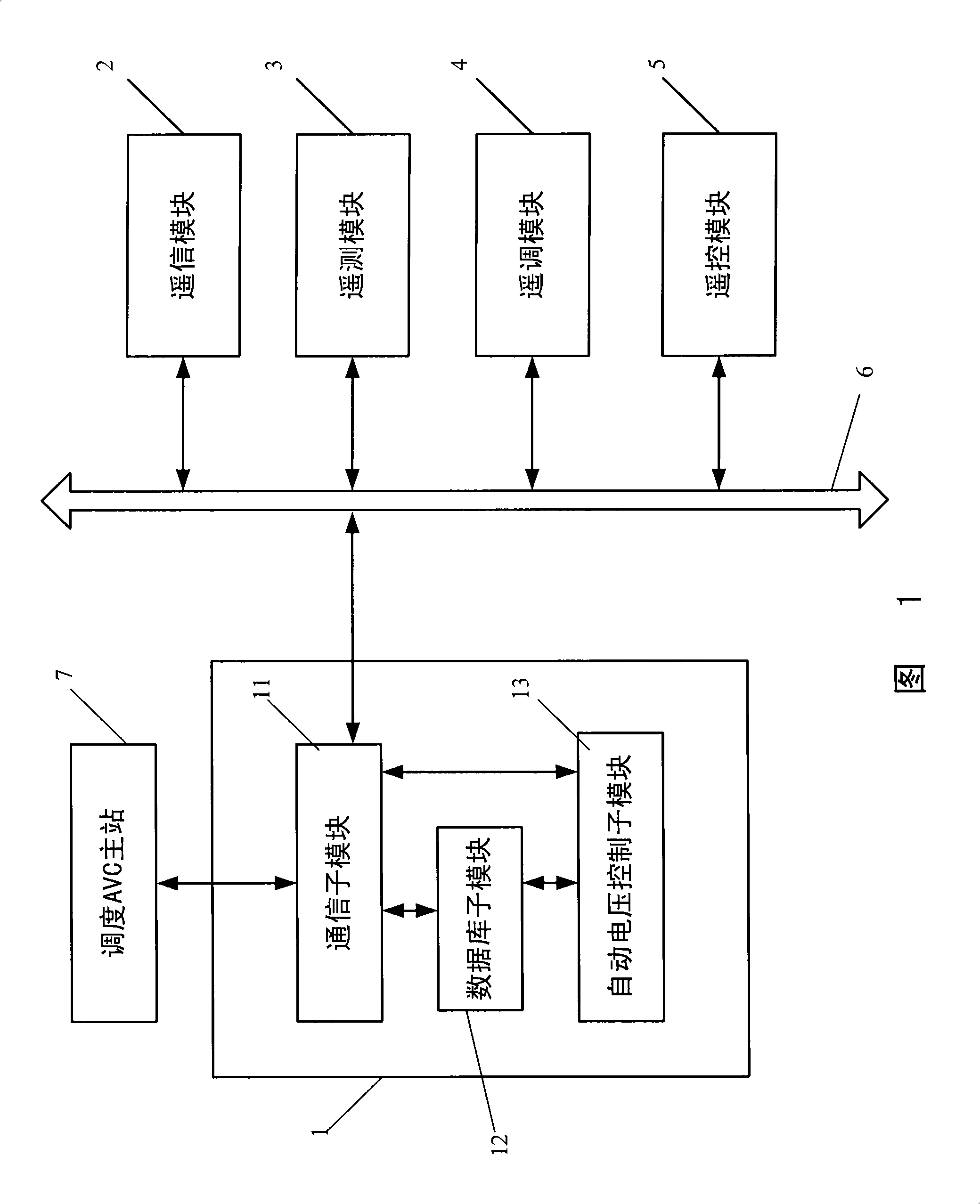

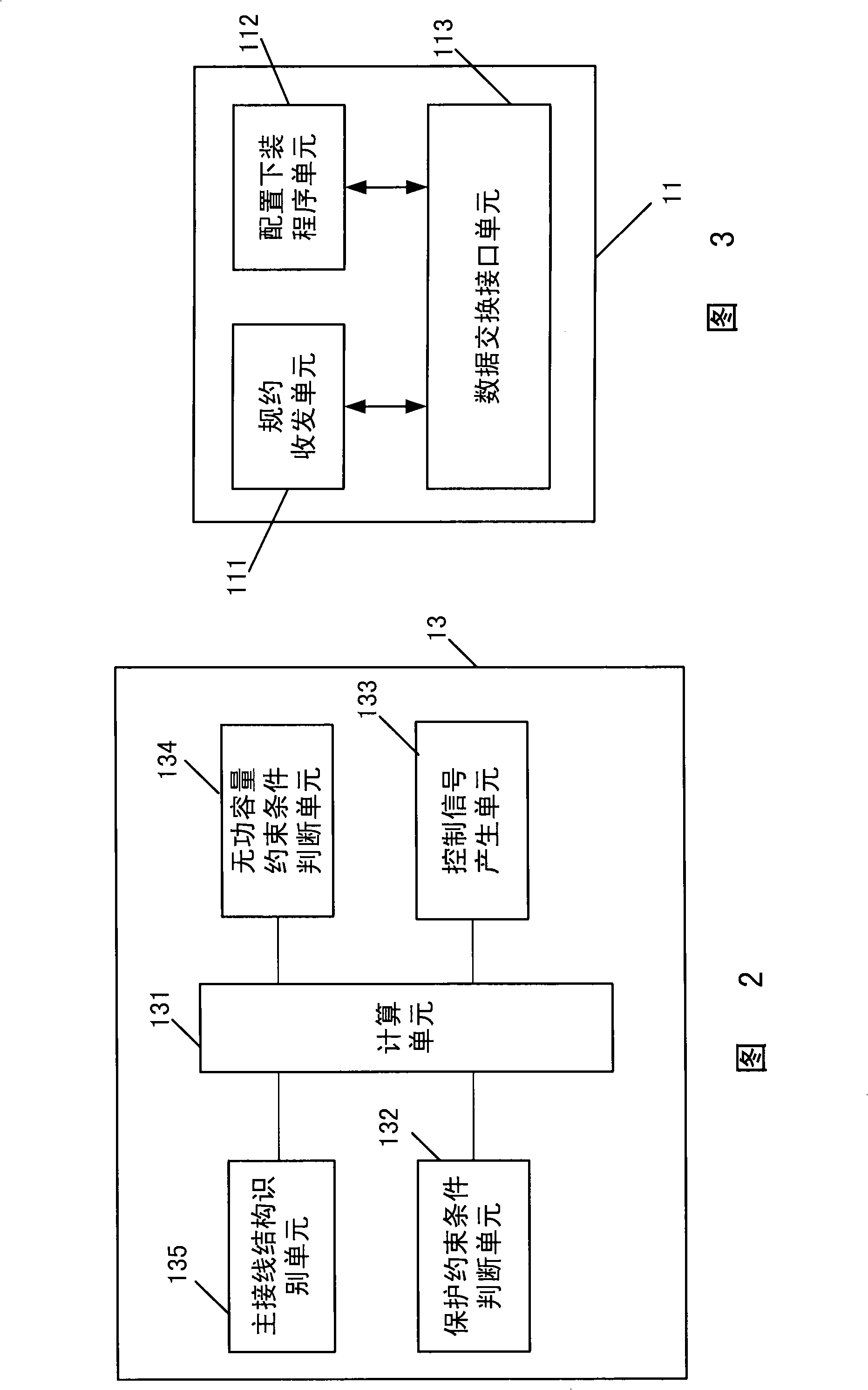

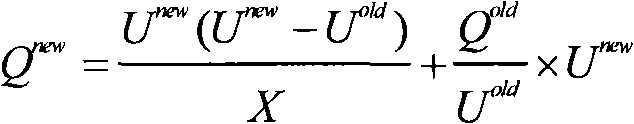

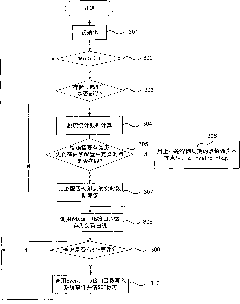

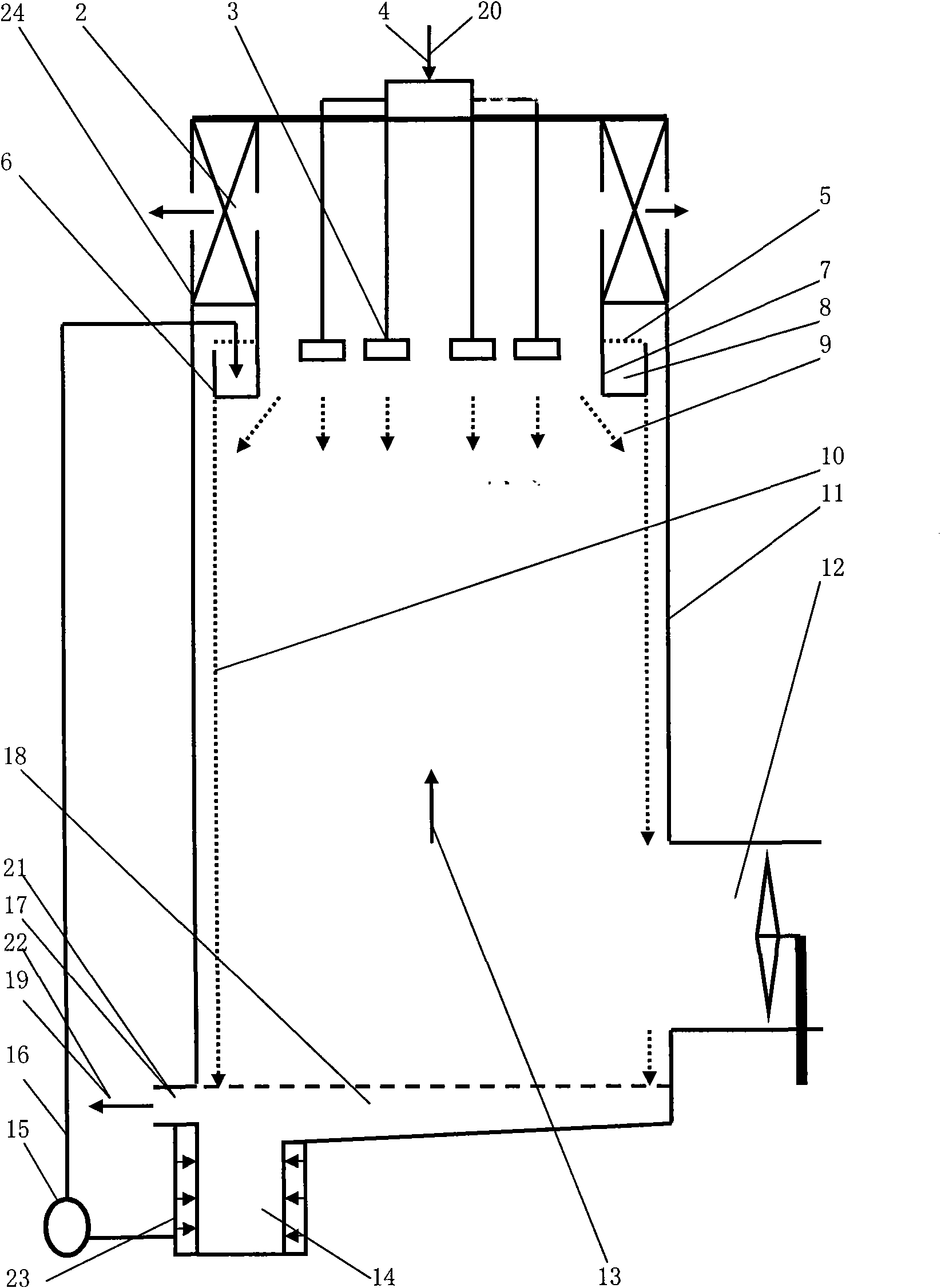

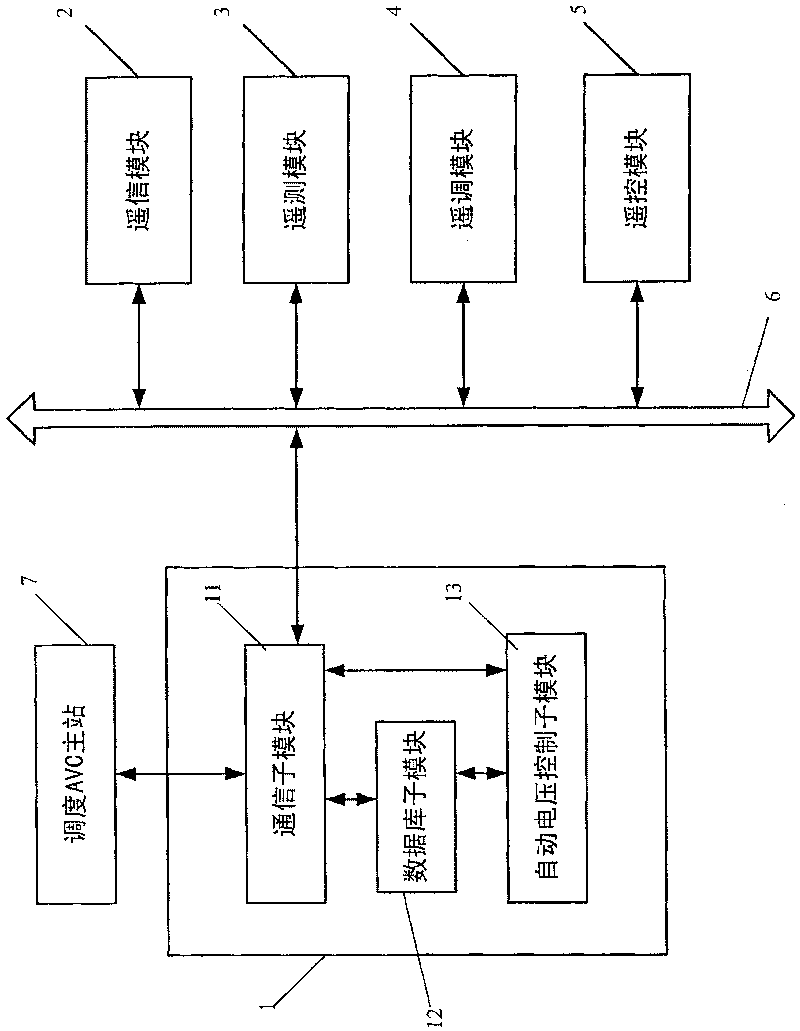

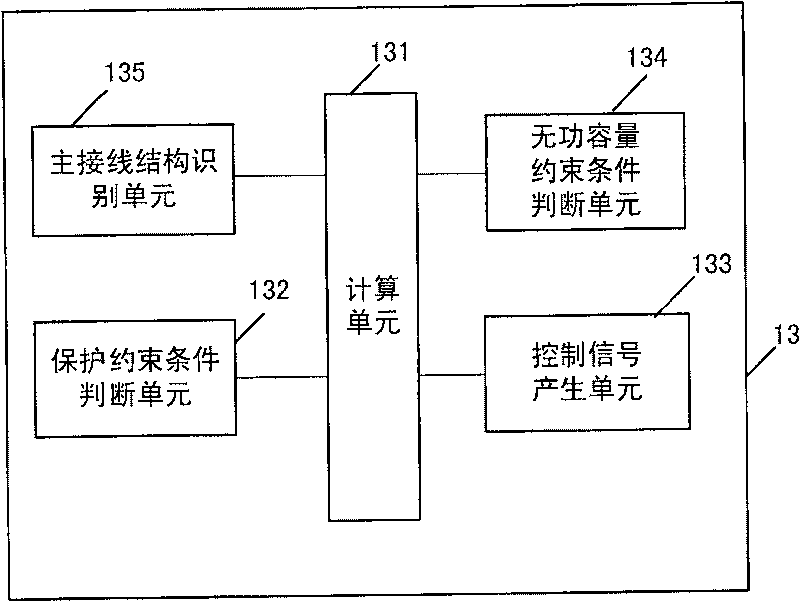

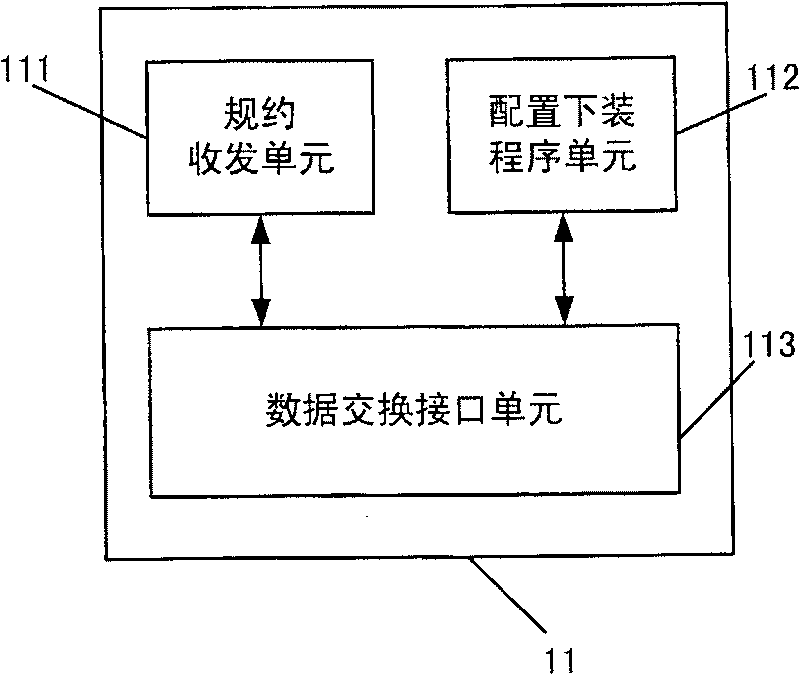

Electric power telemechanical device RTU and method for implementing automatic voltage control of generating plant

InactiveCN101299587AEnsure consistencyGuaranteed operating accuracyComputer controlSingle network parallel feeding arrangementsAutomatic controlPower station

The invention discloses an electric power telemechanical apparatus RTU and a method for realizing the automatic voltage control of the power plant. The inventive electric power telemechanical apparatus includes a central control module, a remote signalling module, a telemetering module, a remote regulating module and a remote control module, wherein the central control module includes a communication submodule, a data bank submodule and an automatic voltage control submodule, which generates the control signal for adjusting the wattless production output of the generating set, based on the data stored in the data bank submodule, and transmits the control signals to the remote regulating module or the remote control module through the communication submodule, then transmits to the generating set which participates in the voltage control through the remote regulating module or the remote control module, realizes the automatic voltage control. The invention gives full play to the function of the electric power telemechanical apparatus, reduces the amount of the situ hardware units, increases the operational precision of the data in the AVC adjusting process.

Owner:上海惠安系统控制有限公司

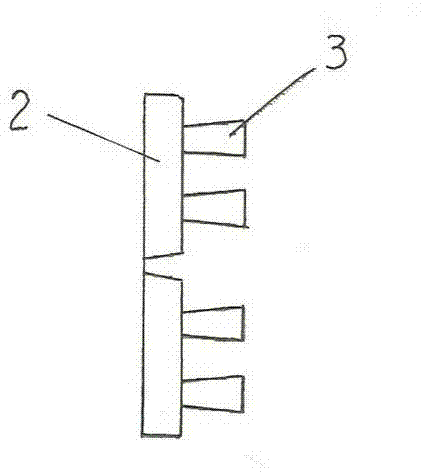

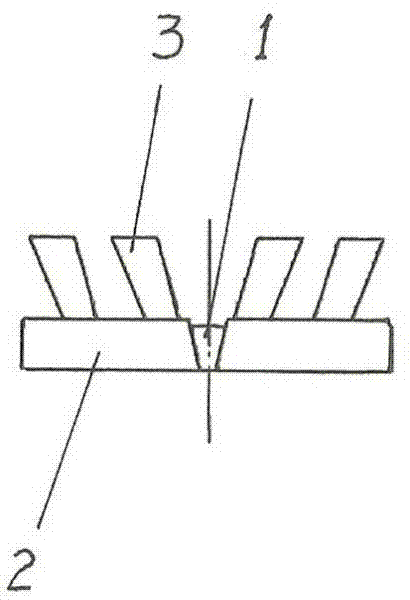

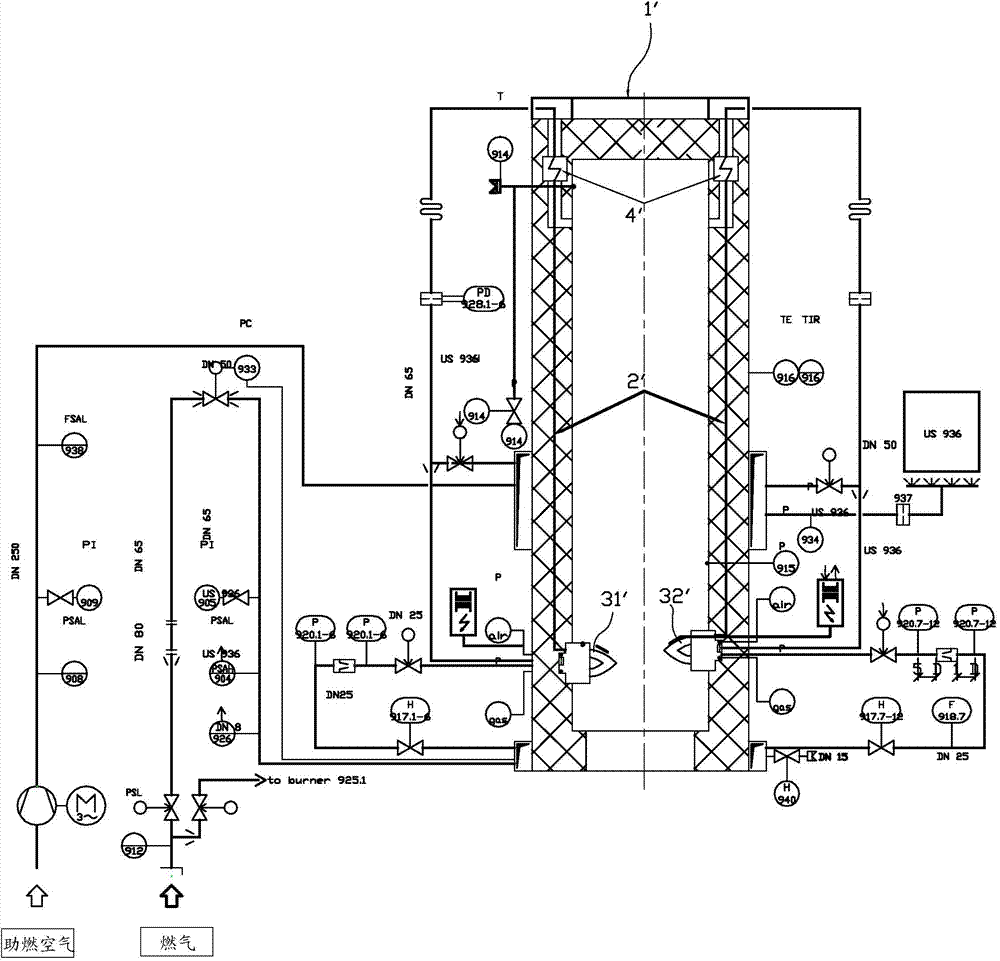

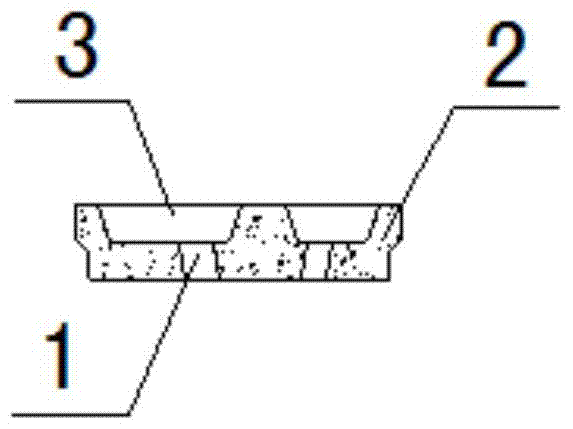

Integral pouring molding method for burner of regenerative heating furnace

InactiveCN102288035ASolve the large amount of engineeringResolution cycleLinings repairEngineeringSlurry

The invention relates to an integral casting-molding method for a heat-storing type heating-furnace burner, which comprises the following steps of: firstly manufacturing cross reinforcing ribs and a burner-spout mould, then arranging a burner body and a heat-storing box, installing the cross reinforcing ribs and the burner-spout mould at an outlet of the heat-storing box, arranging a template forsupporting an inner wall surface on the inner surface of a furnace wall, carrying out integral casting for a wall-body space in the template and the burner-spout mould through a slurry material, dismantling the template for supporting the inner wall surface and the burner-spout mould after the slurry material is solidified and the requirements of an intensity standard are met, and molding a burner spout to form the integral burner together with the burner body and the heat-storing box fixed on the furnace wall of a heating furnace. Through the integral casting-molding method for the heat-storing type heating-furnace burner, the defects of long period, complex construction and high cost of a traditional process are overcome, the service life of the burner on the heating furnace is effectively prolonged, the construction time and the maintenance-engineering quantity are shortened, and the integral casting-molding method is a maintenance-construction method which has the advantages that the time is saved, the labor is saved, the cost is effectively lowered, and the service lives of the heating furnace and the burner are prolonged.

Owner:河北二十冶建设有限公司

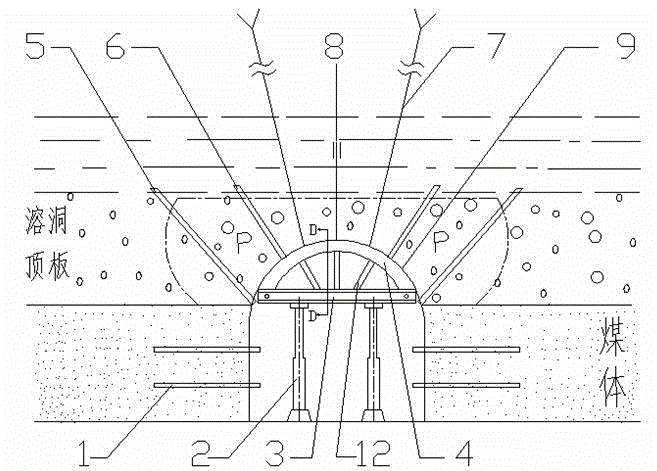

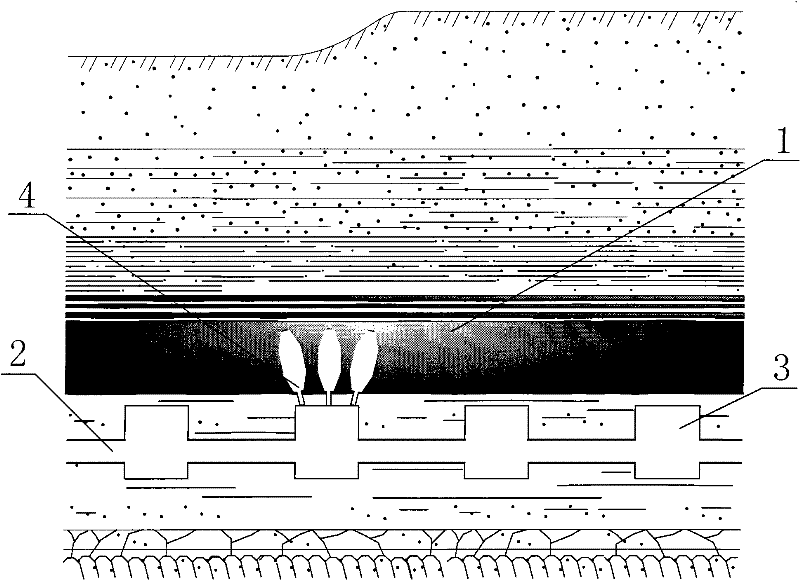

Rapid composite roof roadway support method for high-stress water guiding karst cave group

InactiveCN104594926AResistance to impact damageOvercoming Difficulties in ReworkMine roof supportsTunnel liningStructure of the EarthKarst

The invention provides a rapid composite roof roadway support method for a high-stress water guiding karst cave group. The rapid composite roof roadway support method comprises the steps that anchor rods are driven into the two sides of a roadway for support, self-drilling type grouted anchor rods are implanted into the arch springings and the vault of the roadway, rapid-hardening grouting materials are injected, and then a rapid roof reinforcing area is formed; secondly, profile steel is adopted, a roadway cross-section reinforcing support structure corresponding to the roadway roof anchor rod support is formed, and after jacking support is achieved through single hydraulic props, an arch supporting composite roof structure is formed through welding. By the adoption of the rapid composite roof roadway support method for the high-stress water guiding karst cave group, the composite roof of the high-stress karst cave group is effectively controlled, the maintenance work amount of roadways of the same type is greatly reduced, and coal mine production benefits and economic benefits are effectively improved.

Owner:TAIYUAN UNIV OF TECH

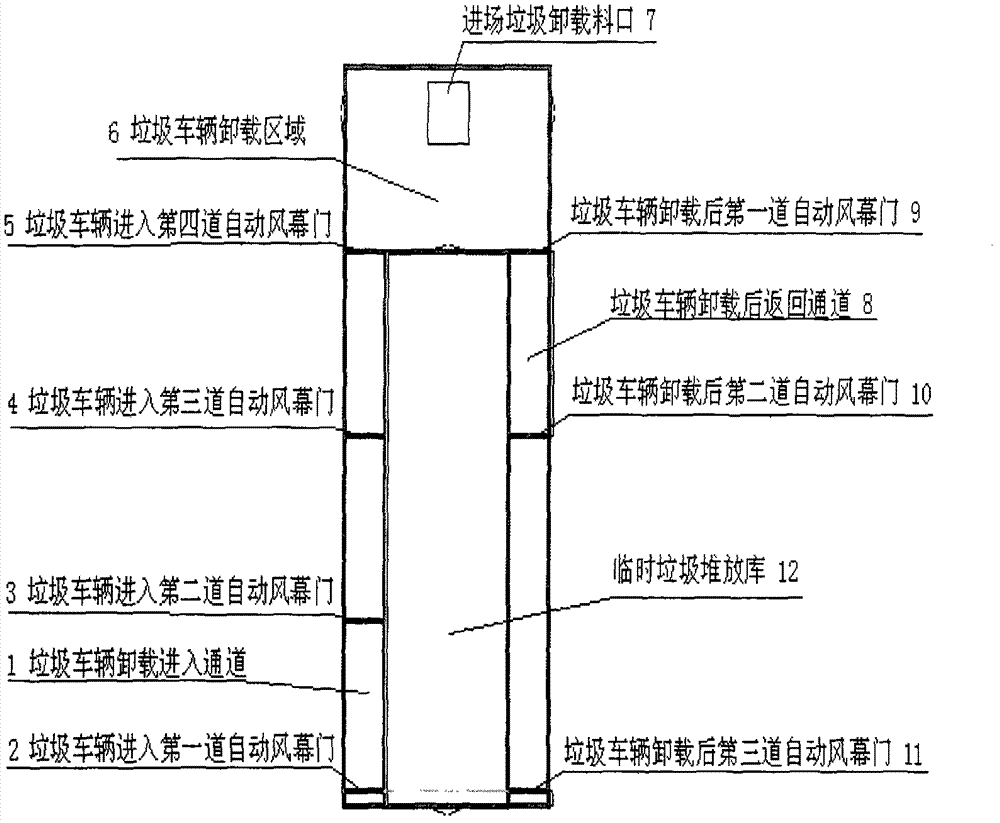

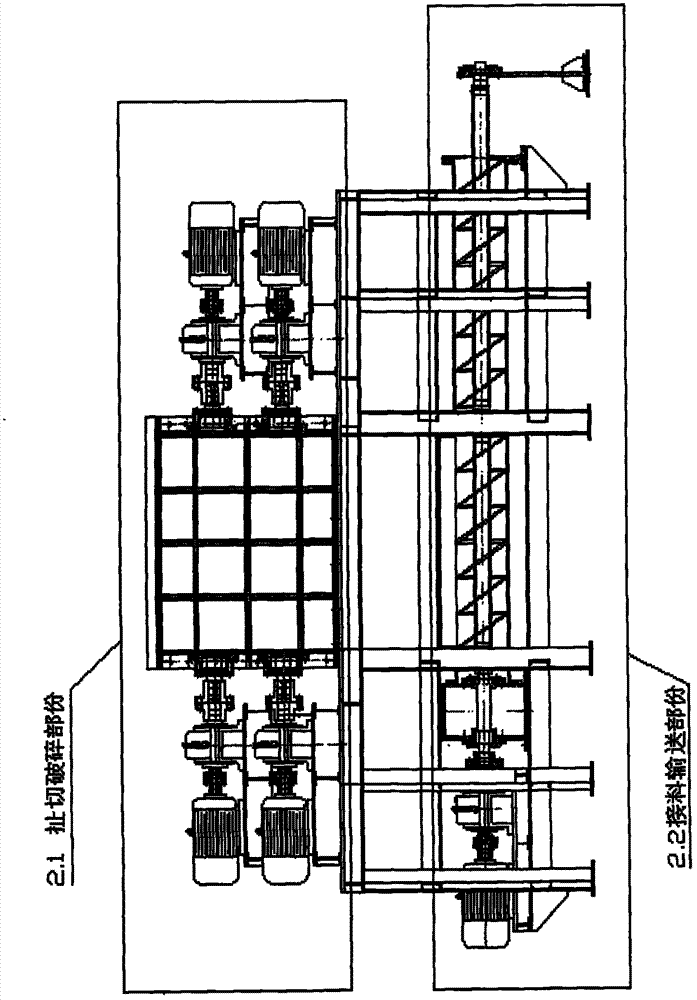

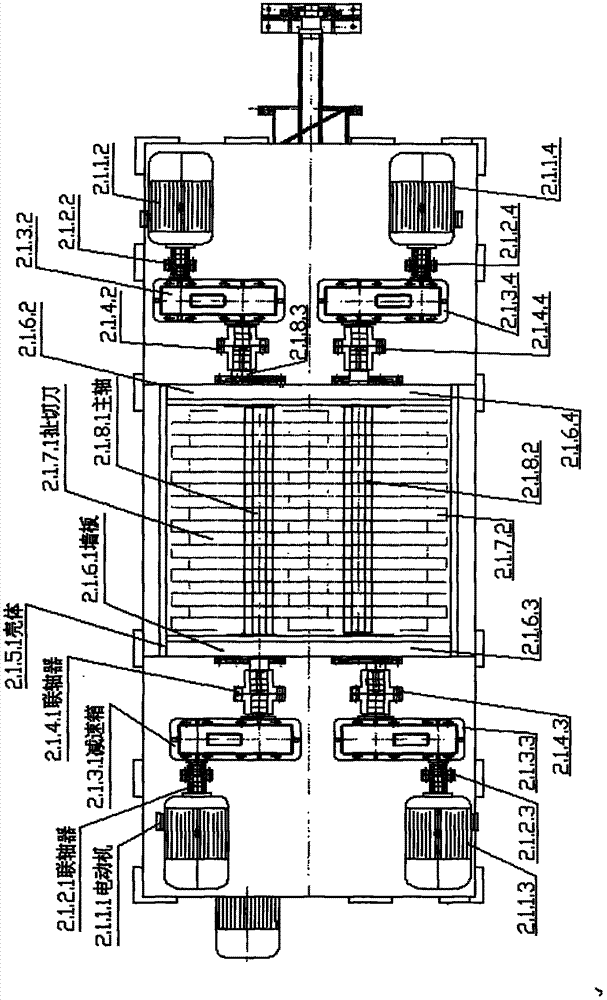

Equipment and industrialization method using municipal solid waste to produce composite dry powder fuel for power generation of coal-fired power plant

InactiveCN102784791ADoes not affect operationReduce the amount of maintenance workSolid waste disposalWaste processingNonferrous metal

The invention relates to the field of environmental protection energy, and especially relates to equipment and an industrialization method using municipal solid wastes to produce composite dry powder fuel for power generation of coal-fired power plants. According to compositions and physical and chemical properties of the municipal solid wastes, through the advanced technology of step-by-step sorting, drying at room temperature, modification composition and waste utilization, and equipments, the industrialization method include that: metals, silicate materials and plastics therein are sorted out through a sorting system; an ultrafine dry powder is produced by using room-temperature fine dewatering drying equipment; and additives are added for modification processing to produce the composite dry powder fuel for power generation of the coal-fired power plants; while the sorted and processed liquids, solids, and gases such as ferrous metals, non-ferrous metals, silicate materials (brick, stone, glass, sand, etc.), waste water, waste gases, and plastics are respectively processed using different processes and equipments. The equipment and the industrialization method not only can inexpensively and efficiently meet the requirements of quantitative reduction, stabilization, harmlessness, and resource utilization for wastes, but also realize the integrated utilization, making the wastes be a treasury bringing benefit to human continuously, and actually realizing a revolutionary breakthrough for municipal waste processing.

Owner:谭林立

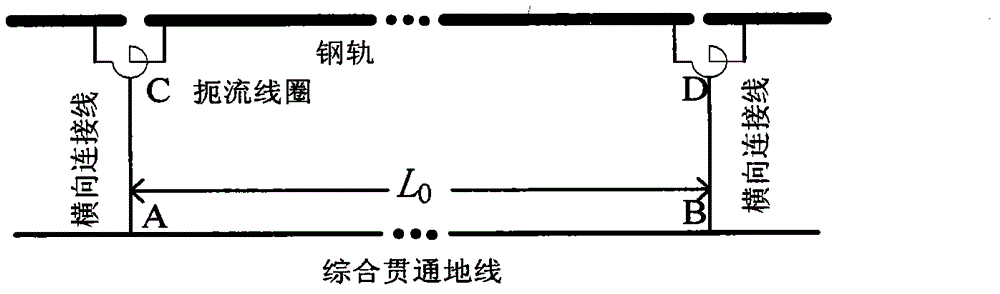

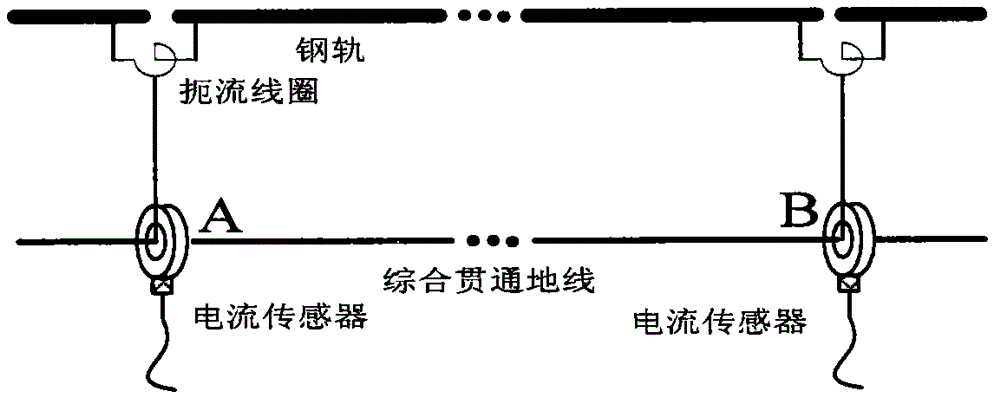

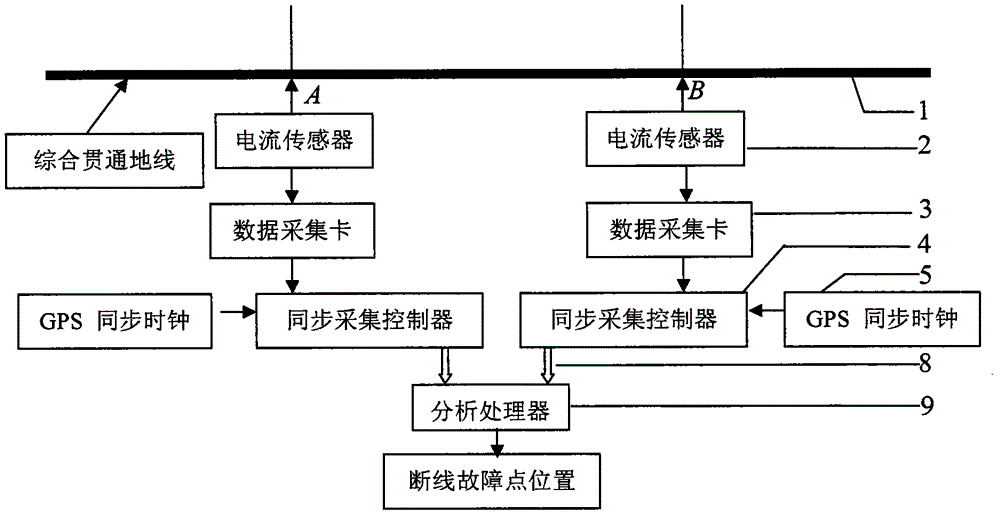

Method for detecting disconnection fault point position of high-speed railway comprehensive through ground wire

InactiveCN103336219AReduce the amount of maintenance workShorten maintenance timeFault locationCurrent sensorElectric current

The invention discloses a method for detecting a disconnection fault point position of a high-speed railway comprehensive through ground wire. According to the method, current sensors are disposed at two adjacent connecting points where the comprehensive through ground wire and steel rail choking coils are transversely connected, signals of sensors before any disconnection fault and after the disconnection fault are respectively measured, coefficient of proportionality of the two sensor current signals are then obtained and are brought into relative formulas for processing, and the disconnection fault point position of the comprehensive through ground wire is obtained. According to the method, the comprehensive through ground wire does not need to be dig out from earth segment by segment, the normal operation of trains is not affected, engineering amount of the overhaul of the comprehensive through ground wire is substantially reduced, the overhaul time is shortened, and overhaul efficiency is improved.

Owner:SOUTHWEST JIAOTONG UNIV

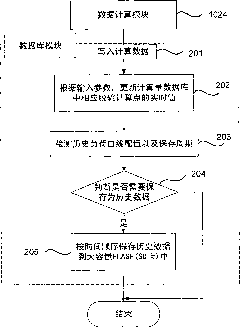

Measure and control device and method for collecting and storing data

InactiveCN101825879AImplement Statistical ComputingGuaranteed real-timeComputer controlSimulator controlReal-time dataPrimary station

The invention provides a measure and control device for collecting and storing data, which is characterized by comprising a central control module, wherein the central control module comprises a communication module and a databank module, the communication module carries out data communication between a main station or a monitoring collector and the databank module, the databank module is used for storing the collected data and carries out data interaction with the communication module, the databank module comprises a real-time databank submodule, a history databank submodule and a calculation amount databank submodule, wherein the real-time databank submodule is used for storing real-time data, the history databank submodule is used for storing history data, and the measure and control device also comprises a data calculation module and a supply and collect module. The invention also provides a method for collecting and storing data. The device and the method complete real-time data collection, data storage and data transmission on one measure and control device, reduces the data loss, and improves the data reliability.

Owner:上海惠安系统控制有限公司

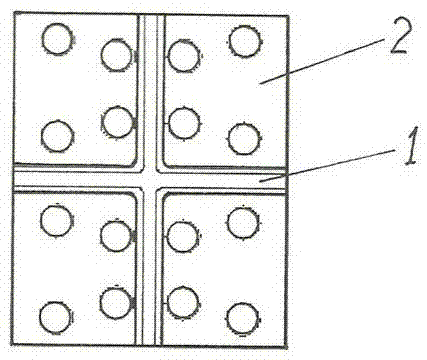

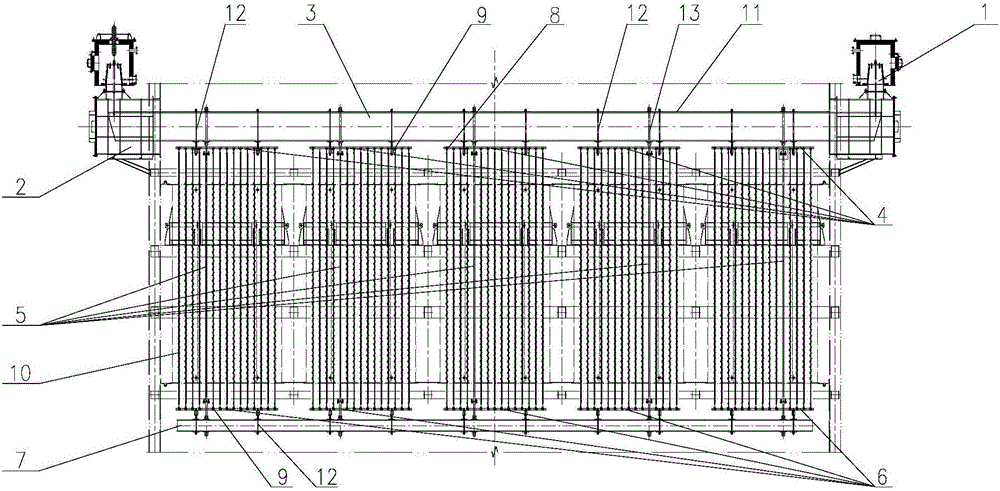

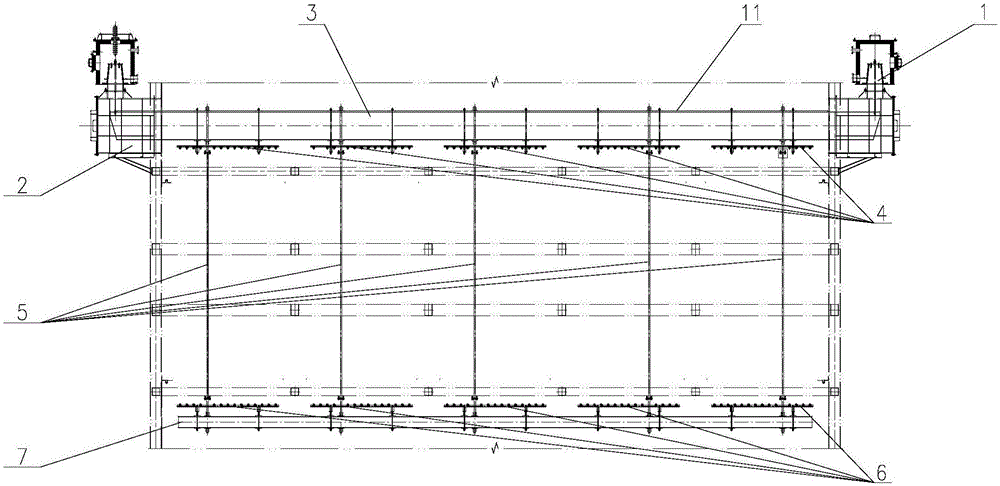

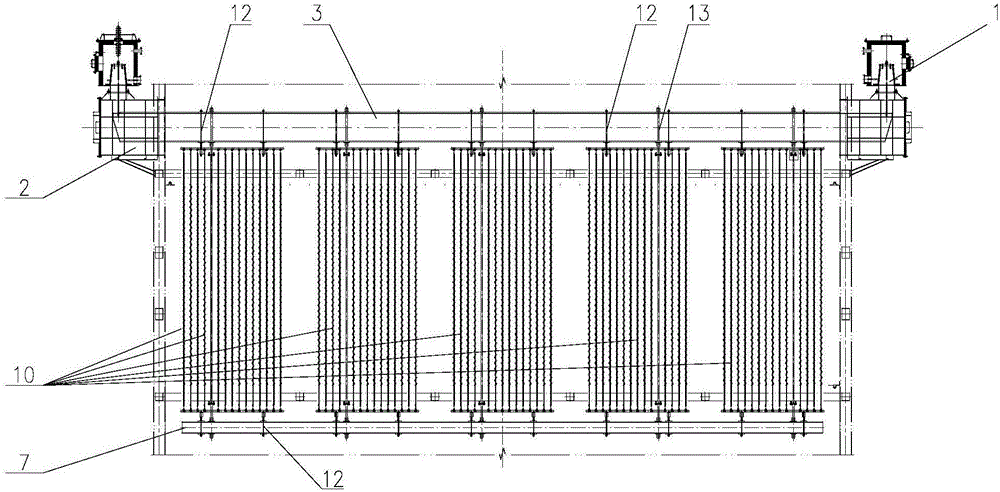

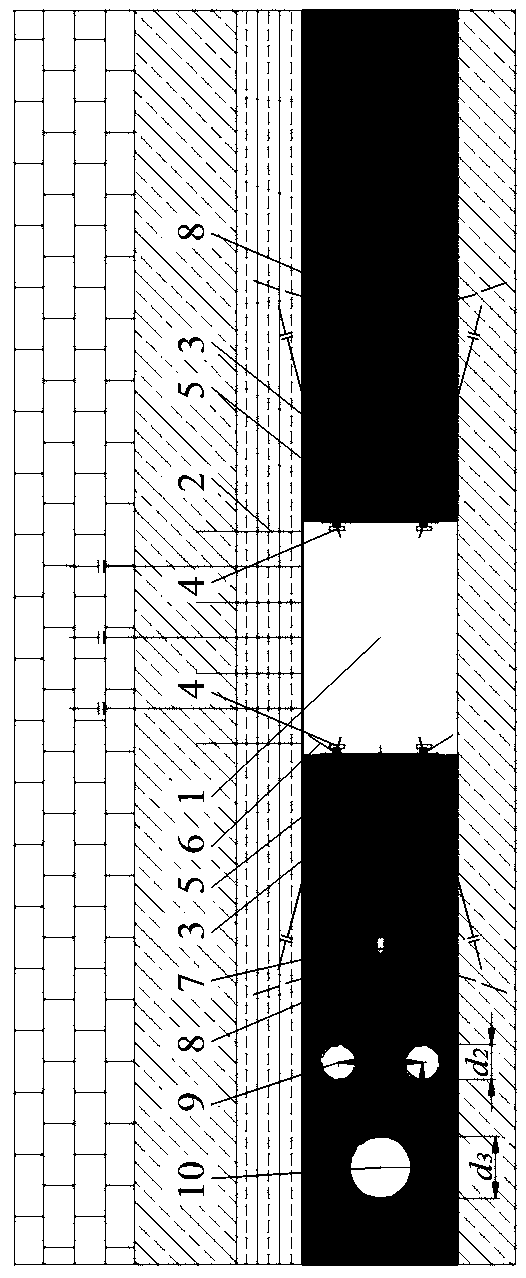

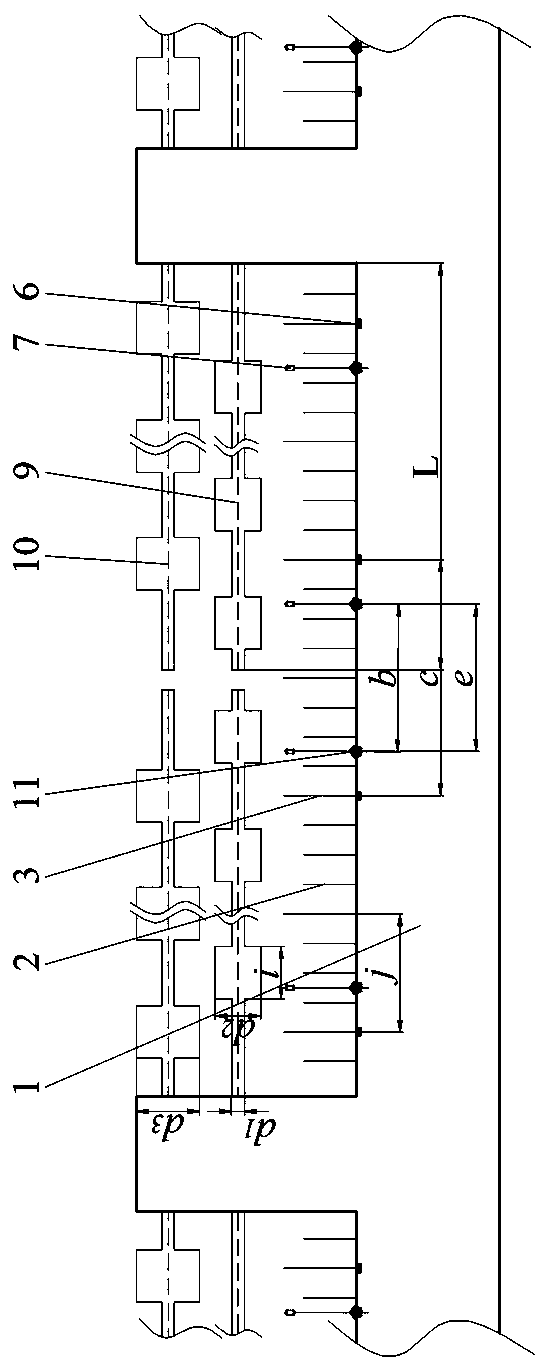

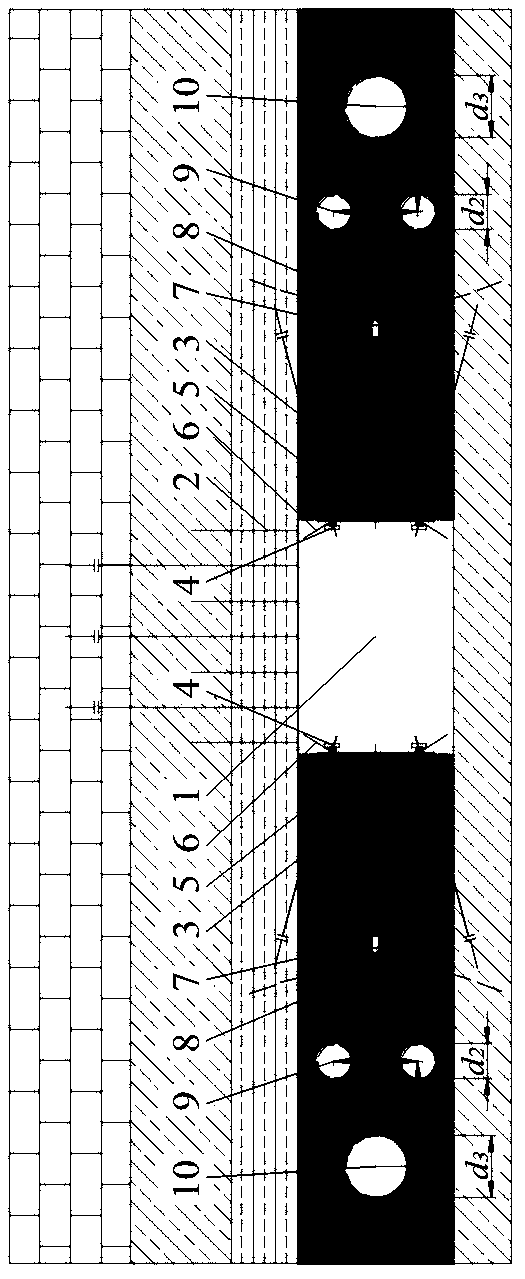

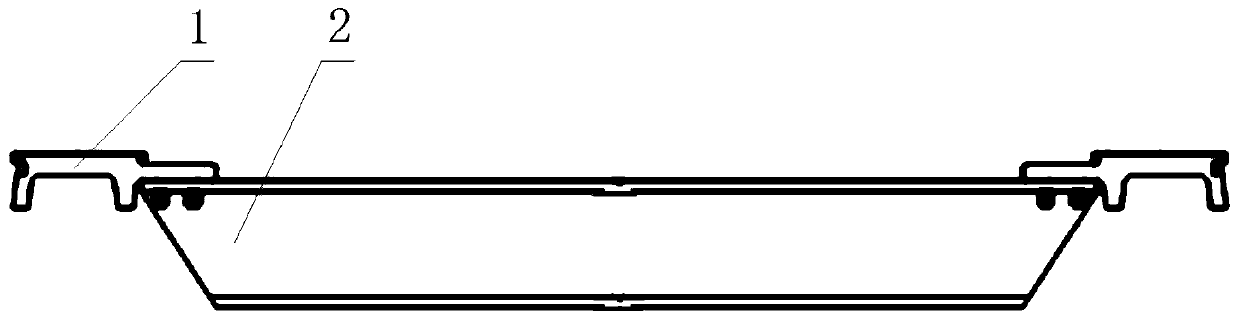

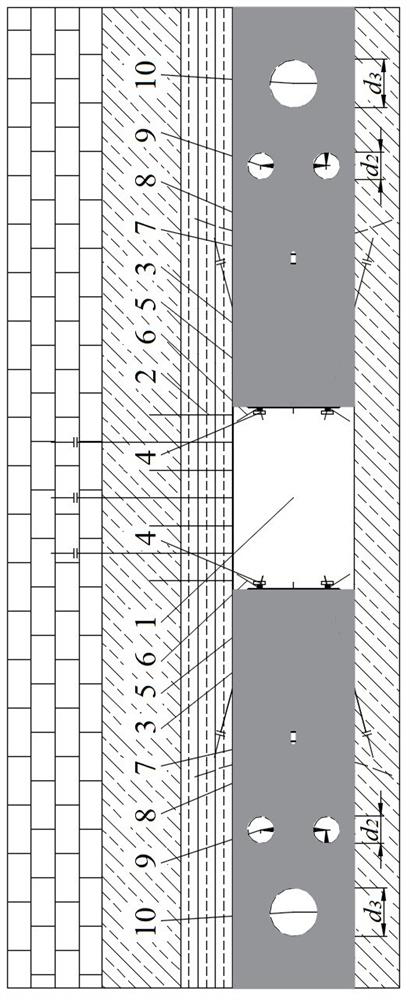

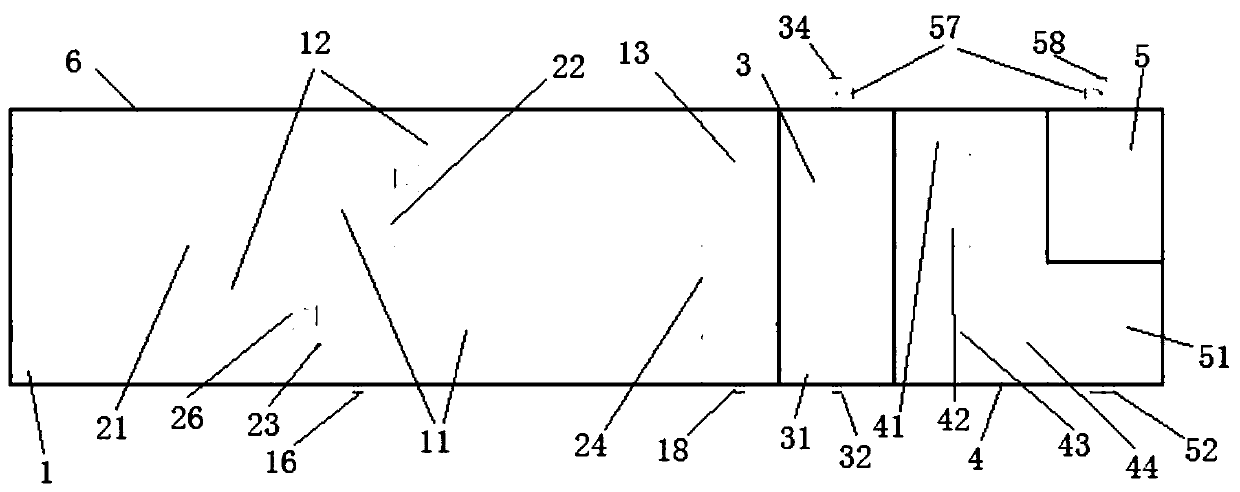

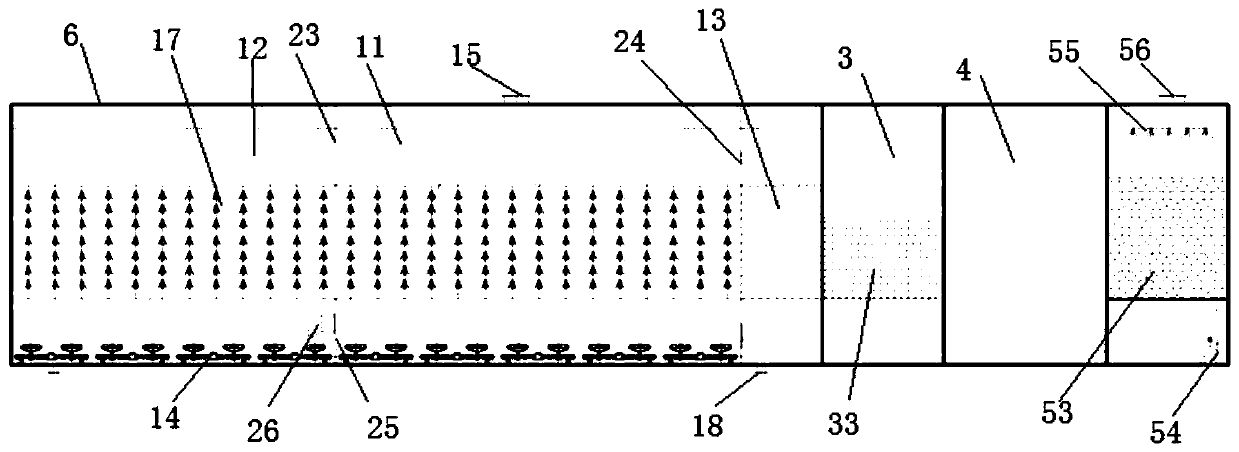

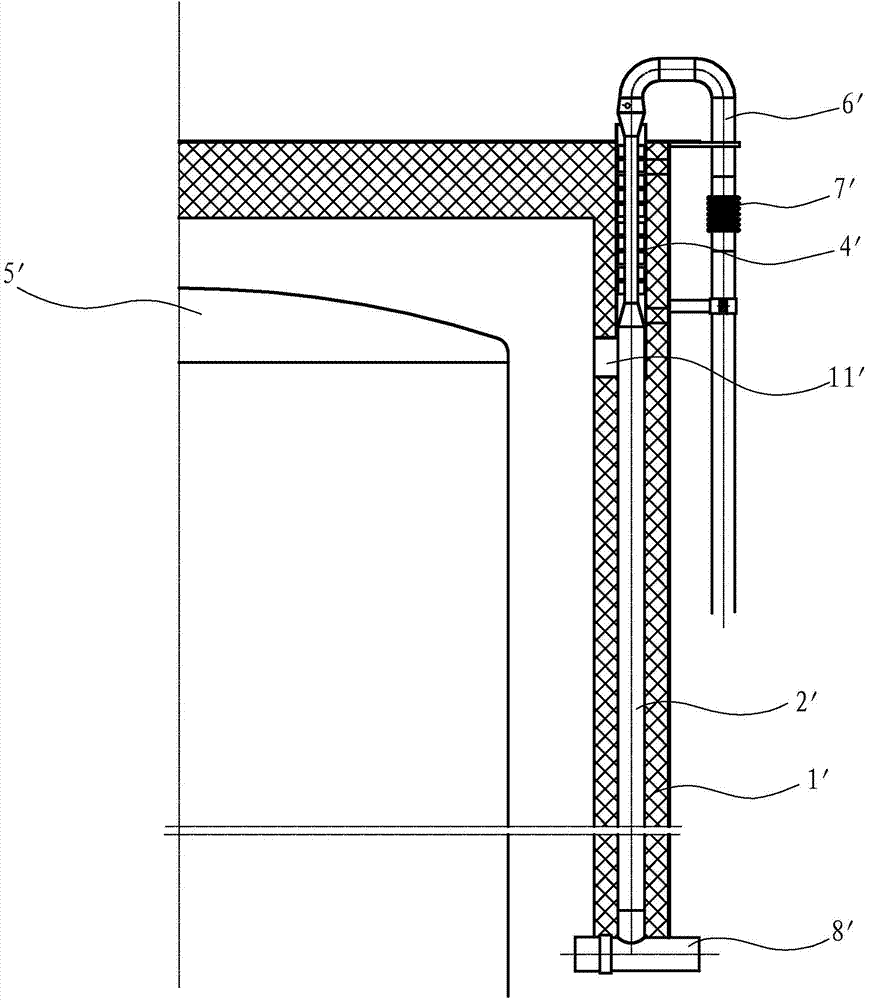

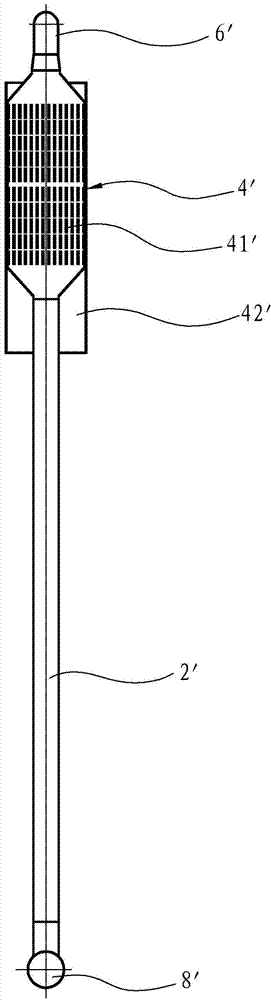

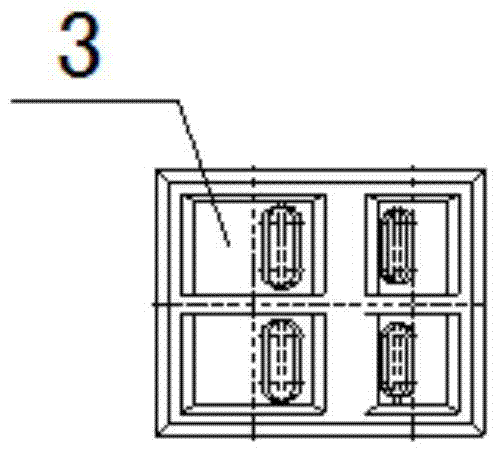

Cathode hanging system for wet dust remover non-tension device

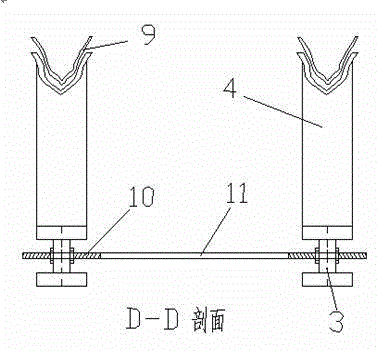

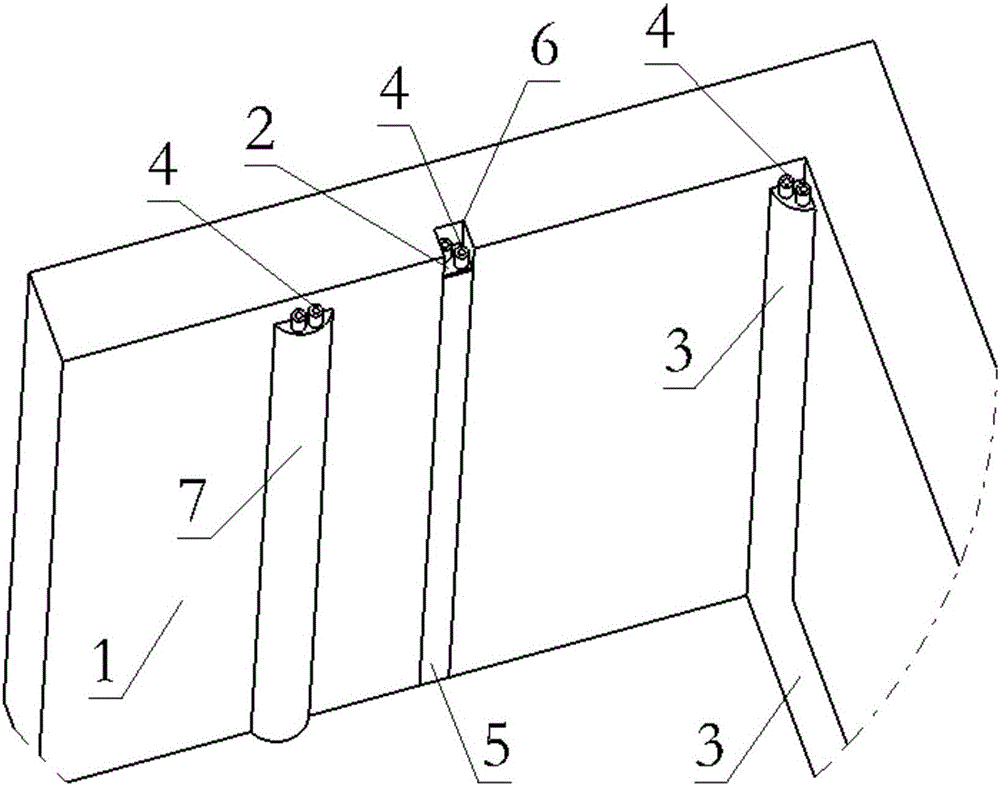

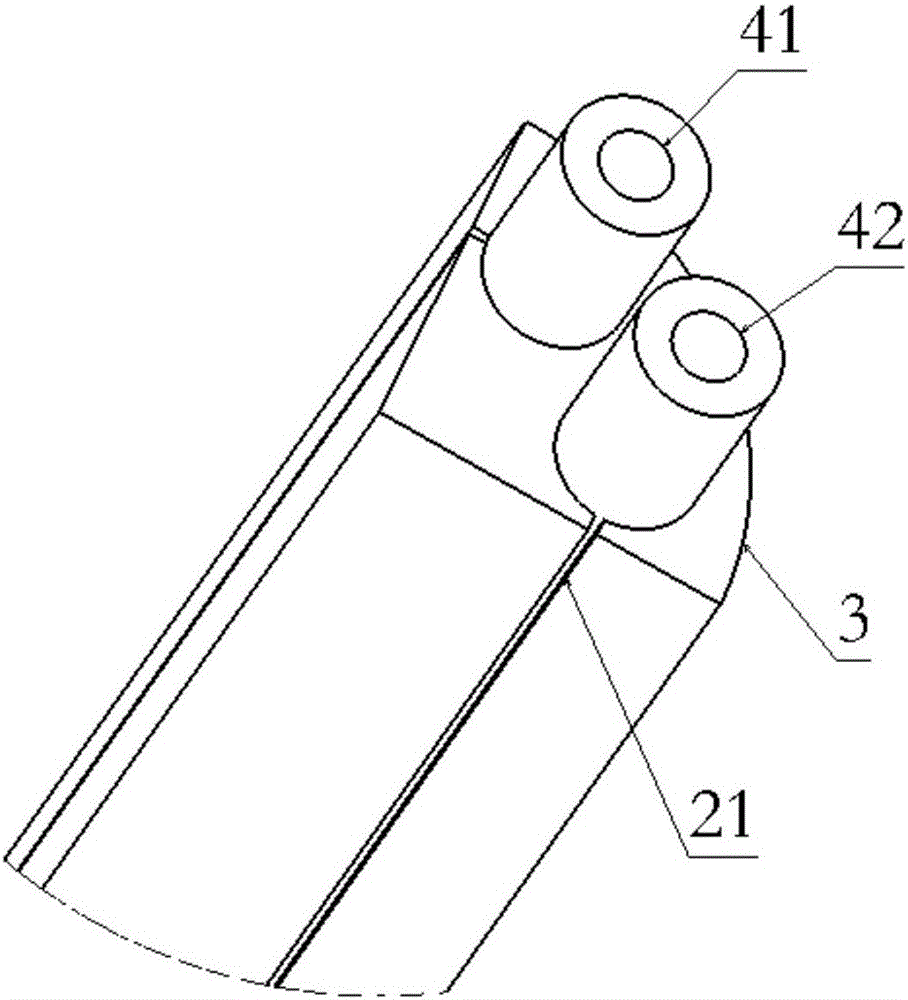

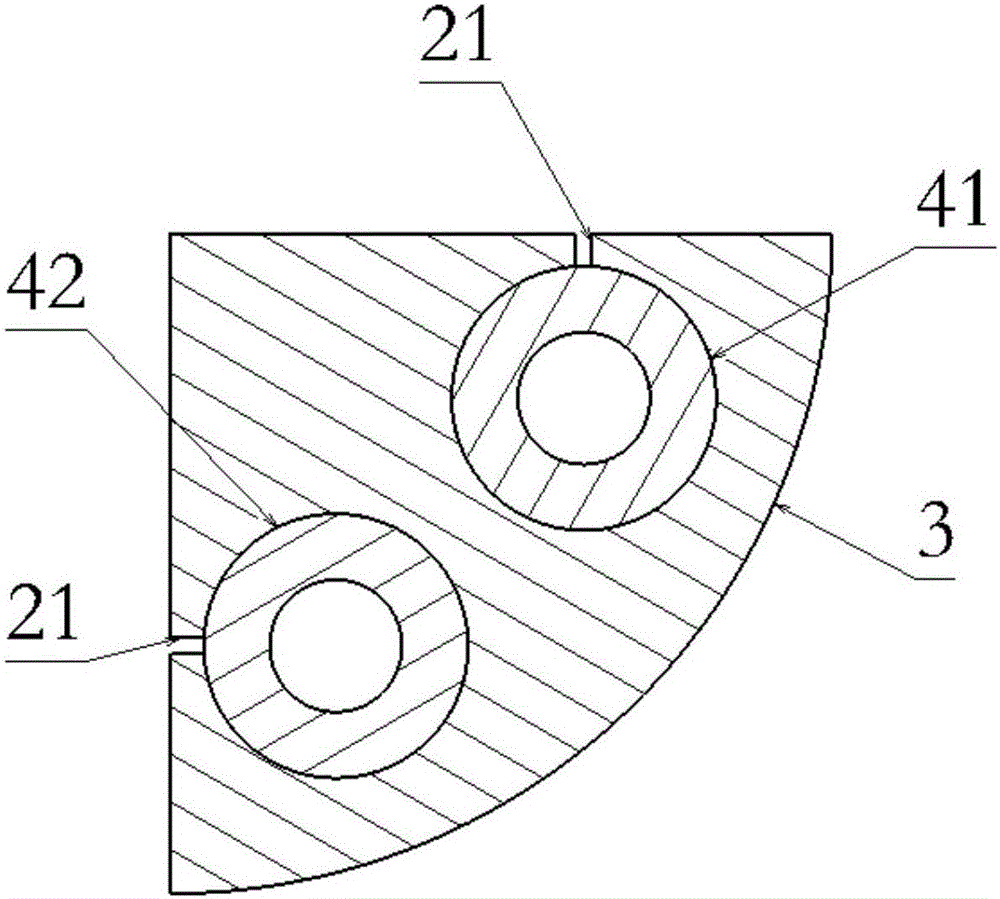

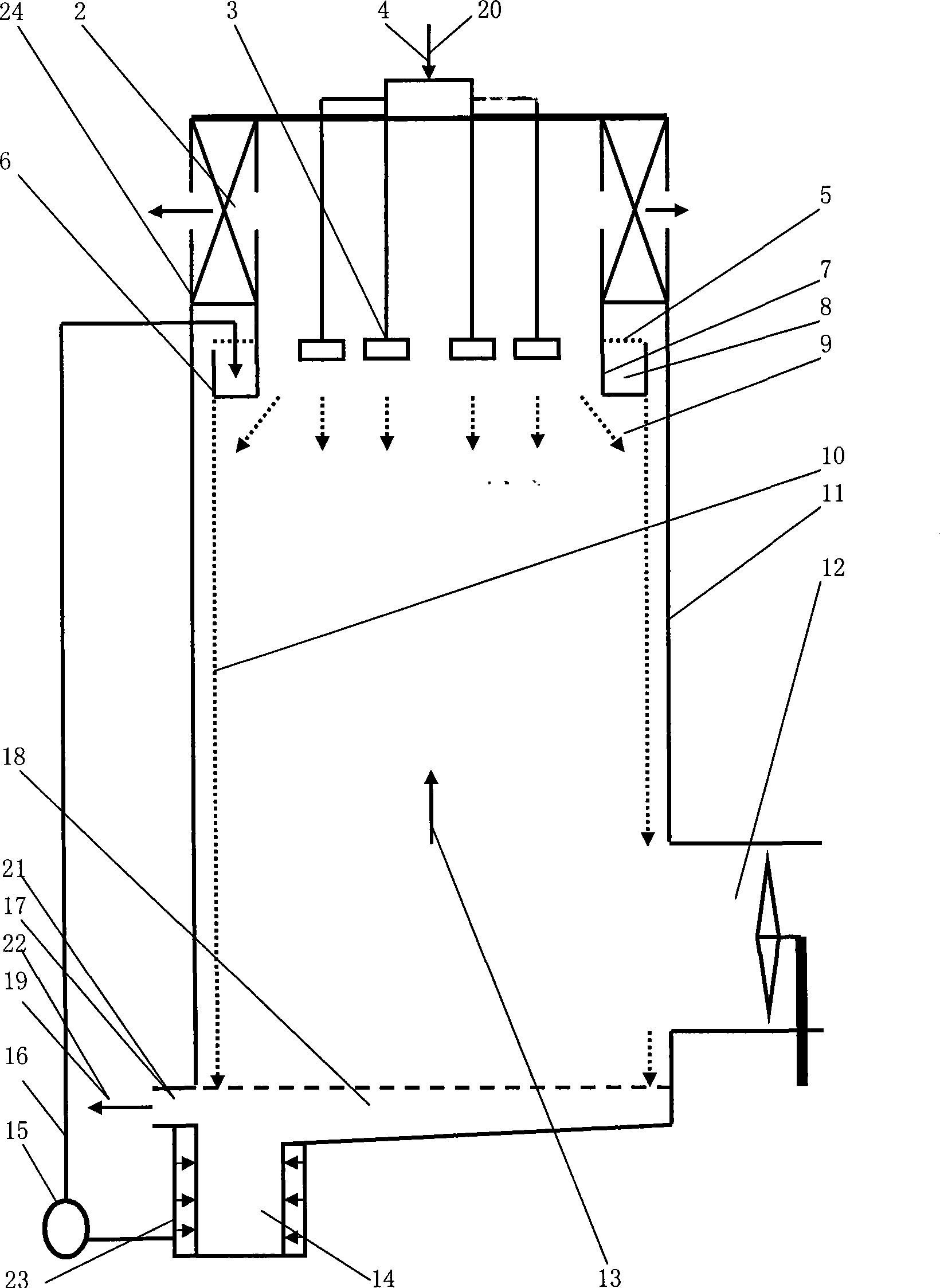

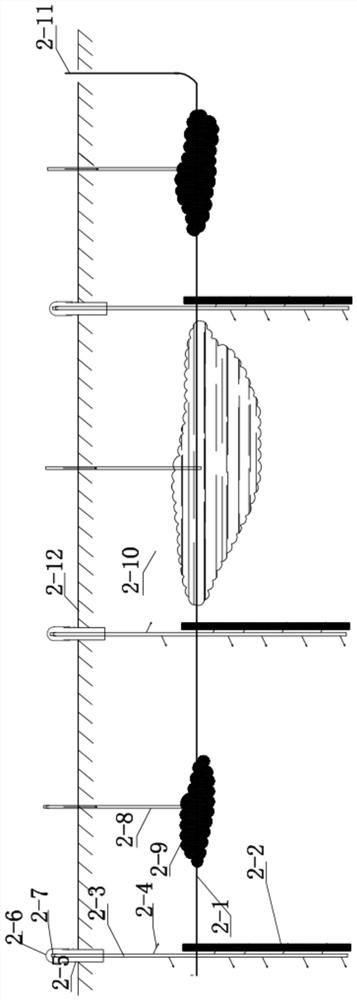

PendingCN106423564AAvoid the risk of condensation creepageImprove stabilityElectrode carrying meansExternal electric electrostatic seperatorProcess equipmentEngineering

The invention discloses a cathode hanging system, in particular to a cathode hanging system for a wet dust remover non-tension device, and belongs to the technical field of tail smoke treatment of power plant boilers. Wall penetrating protection devices (2) in the system are welded on two sides of a wet dust remover shell wall plate, and are provided with insulator box hanging systems (1); an upper cathode main beam (3) is arranged between the insulator box hanging systems (1); an upper cathode frame (4) is hung at the lower part of the upper cathode main beam (3); the upper cathode main beam (3) is hung with a lower cathode frame (6) through a hanging rod (5); and a cathode wire (10) is positioned between the upper cathode frame (4) and the lower cathode frame (6). The system simplifies the process equipment, saves the construction cost, improves the hanging stability, and reduces the maintenance workload and the maintenance cost.

Owner:CHINA HUADIAN ENG +1

Pressure relief and monitoring method for continuous large deformation of deep roadway coal side

ActiveCN111365077AChange stress stateReduce stressMining devicesUnderground miningSupporting systemMining engineering

The invention discloses a pressure relief and monitoring method for continuous large deformation of deep roadway coal sides. The pressure relief and monitoring method mainly aims at solving the problems that continuous large deformation of two sides of a deep roadway and damage of a support system have to be expanded, brushed and repaired all the time to guarantee functions of the roadway, and themaintenance cost is greatly increased. According to the pressure relief and monitoring method for continuous large deformation of the deep roadway coal sides, large pressure relief hole groups parallel to the axial direction of the roadway are arranged in the deep areas of the two sides of the roadway, surrounding rock deformation energy can be partially released, the bearing stress peak values of the two sides can be greatly transferred to the deep part, and meanwhile a large compensation space is provided for continuous migration of deep coal bodies to the roadway space; the pressure reliefholes are drill holes having different numbers and manners and constructed by arranging drill sites on two sides of the roadway, and have different diameters by means of radial hydraulic jet flow ormechanical hole expansion; and stress and deformation monitoring systems are arranged on the two sides of the roadway, when stress and deformation are increased, that is, after the hole groups are closed, the pressure relief hole groups are implemented again, long-time effective monitoring and control of deep coal roadway surrounding rocks are achieved, and the roadway maintenance work amount andcost are greatly reduced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Circuit tube for home decoration

The invention discloses a circuit tube for home decoration. The circuit tube comprises circuit tubes, a square tube, a corner tube, an outer tube and a cover plate, wherein a power line or a signal line passes through the circuit tubes to be arranged in the square tube, the corner tube and the outer tube. The power line or the signal line is directly laid at a ground leg and a corner or in a corner line slot by laying the square tube, the corner tube and the outer tube; a circuit detection device is arranged on the corner tube and the outer tube and can be used for detecting a circuit with a fault; and the square tube, the corner tube and the outer tube are made of insulation light materials, convenience is provided for installation and maintenance, the maintenance workload and maintenance cost are greatly reduced, and meanwhile, original home decoration is not damaged.

Owner:蔡明轩

Method for improving metallurgy solution crystallization deposition in air cooling course and air cooling column

InactiveCN101498557AImproved crystalline depositionImprove operational efficiencyCellsTrickle coolersCooling towerUltrasonic radiation

The invention relates to an air cooling tower and a method for improving the crystallization and the sedimentation of metallurgical solution during air cooling process. Metallurgical solution cooled by the air cooling tower is conveyed to the inner upper part of the air cooling tower by a conveyer and then downwards flows along the surface of the inner wall of a tower cylinder to form a liquid film covering the surface of the inner wall of the tower cylinder so that temperature reducing droplets sprayed to the inner wall of the tower cylinder fall into the liquid film on the surface of the inner wall of the tower cylinder but not directly fall to the surface of the tower cylinder so as to prevent droplets from crystallizing and being sedimentated on the inner wall of the tower cylinder; meanwhile, ultrasonic radiation can also be carried out on metallurgical solution cooled by the air cooling tower to refine crystal grains in the air-cooled metallurgical solution; the treated metallurgical solution is conveyed to the inner upper part of air cooling tower and downwards flows along the surface of the inner wall of the tower cylinder to form a liquid film with refined crystal grains, and the liquid film is covered on the surface of the inner wall of the tower cylinder to prevent crystal grains in the liquid film from being sedimentated on the surface of the inner wall of the tower cylinder.

Owner:佛山市兴民科技有限公司

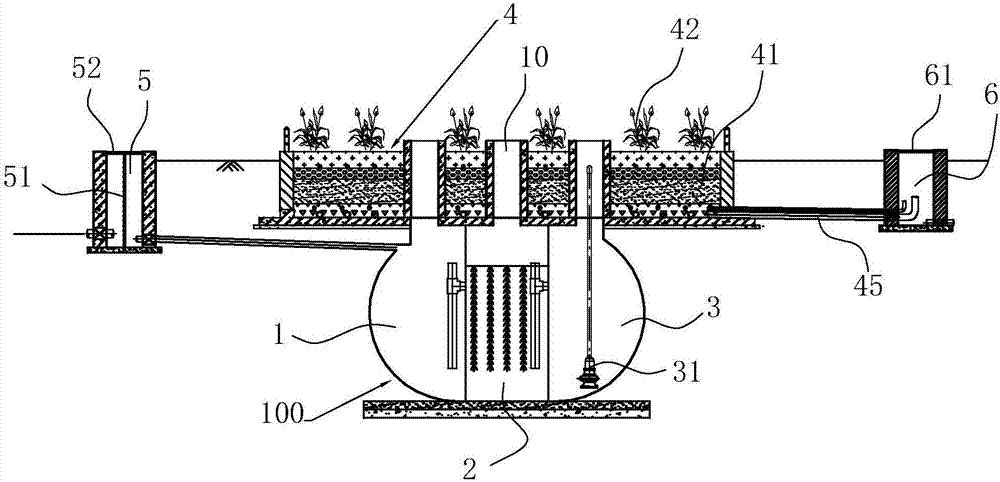

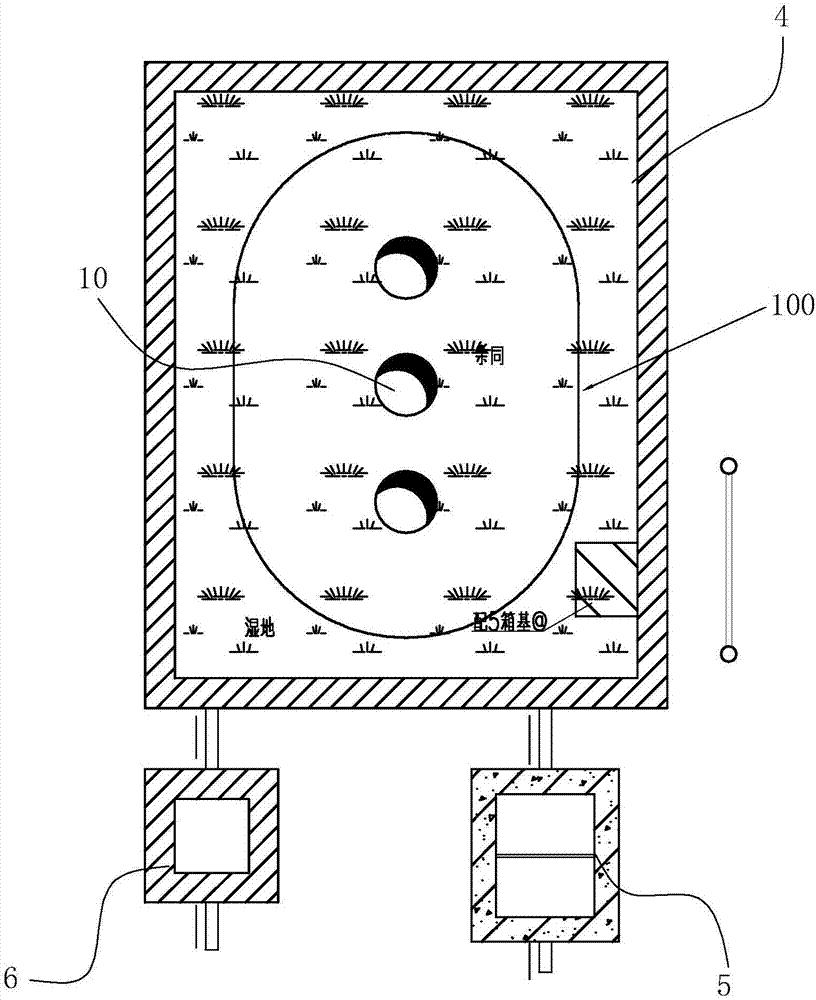

Sewage purification tank

InactiveCN106957131AEasy to handleGood removal effectTreatment involving filtrationTreatment with anaerobic digestion processesConstructed wetlandGrating

The invention discloses a sewage purification tank, which comprises a precipitation separation pond, an anaerobic tank, a regulating lift pond and a constructed wetland which are arranged under the ground, wherein the upper part of the constructed wetland extends out of the ground; manholes exposed out of the ground are formed at the upper ends of the precipitation separation pond, the anaerobic tank and the regulating lift pond respectively; one end of the precipitation separation pond is connected with a grating well and the other end is connected with the anaerobic tank; a water outlet is formed in the other end of the anaerobic tank and is connected with the regulating lift pond; a water outlet end of the regulating lift pond is connected with the constructed wetland through a lift pump; a wetland dielectric layer is laid in the constructed wetland; plants are planted on the wetland dielectric layer; a water distribution pipe is arranged at the upper part of the wetland dielectric layer and is communicated with the regulating lift pond; and a gas distribution pipe and a water collection pipe are arranged at the bottom of the wetland dielectric layer. The sewage purification tank is simple and compact in structure, good in sewage treatment effect, SS in sewage can be effectively reduced and the indexes such as BOD5 and CODcr can be reduced to some extent, and the sewage purification tank is stable in effluent, low in cost and small in floor area and can be adapted to stage construction and household construction of big or small sewage treatment plants of new villages and towns.

Owner:浙江润润环保能源科技有限公司

Pile type spur dike body vibration pile sinking construction method

The invention discloses a pile type spur dike body vibration pile sinking construction method. The method includes the following steps of (a) construction of ramps and shortcuts, (b) preparation before pile sinking and foundation cleaning, (c) pile lifting and sheet pile transporting and positioning and (d) sheet pile sinking through vibration. According to the method, reinforced concrete sheet piles are used as a foundation of a spur dike to replace a rockfill spur dike, the foundation is deep, the spur dike can keep stable under the effect of tidal bore and flood scouring, and therefore compared with the traditional rockfill spur dike, the spur dike with the reinforced concrete sheet piles as the foundation can better bear impact of the tidal bore, is not prone to being damaged, is less in maintenance work amount during operating period, overcomes the defect of frequent emergency rescue, has a higher quality safety coefficient, can avoid the situation that river banks are eroded and damaged and a river bed is scoured due to impact of water flow of rivers, improves fairways, forms shoals, conserves water and soil, maintains fluvial facies, and protects water ecological diversity. The construction method is high in practicability and low in post-maintenance cost and has high applicability, considerable economic benefits, social benefits and ecological benefits.

Owner:浙江钱塘江水利建筑工程有限公司

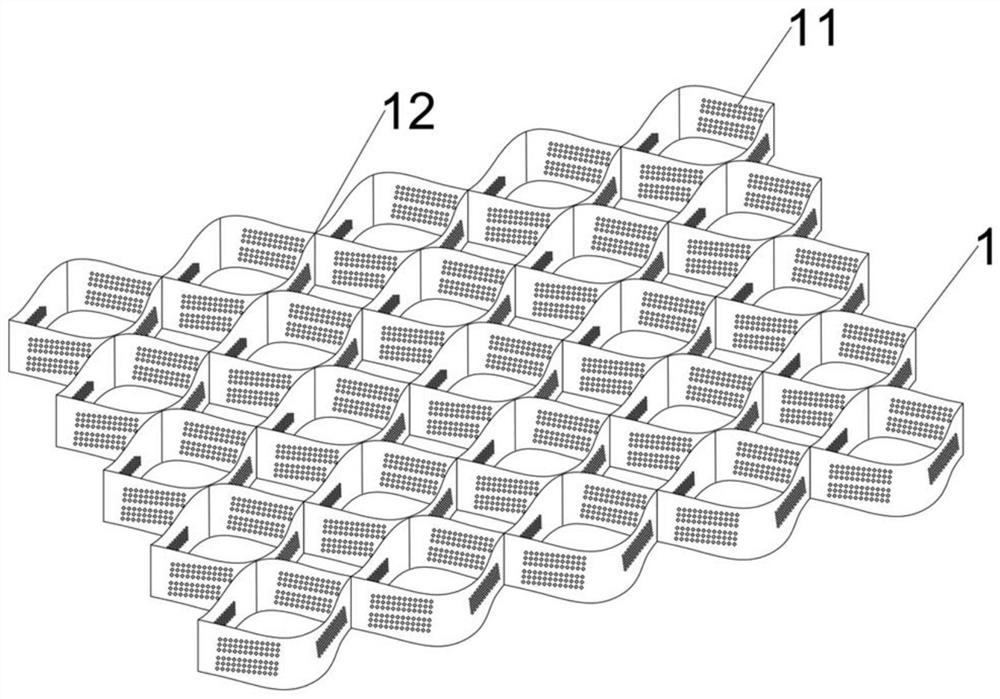

Honeycomb type scour prevention and siltation promotion structure for offshore wind power single pile foundation

PendingCN112900469AIncrease roughnessReduce flowClimate change adaptationFoundation engineeringUltrasonic weldingArchitectural engineering

The invention discloses a honeycomb type scour prevention and siltation promotion structure for an offshore wind power single pile foundation. The honeycomb type scour prevention and siltation promotion structure comprises a honeycomb device and an anchoring system, the honeycomb device is of a flexible structure formed by welding a plurality of honeycomb lattice chambers through ultrasonic waves, and holes are formed in the side face of each honeycomb lattice chamber. During use, pulling force is applied to the honeycomb device through the anchoring system, so that the honeycomb device is unfolded around the offshore wind power single pile foundation to be in a grid state.

Owner:TIANJIN UNIV

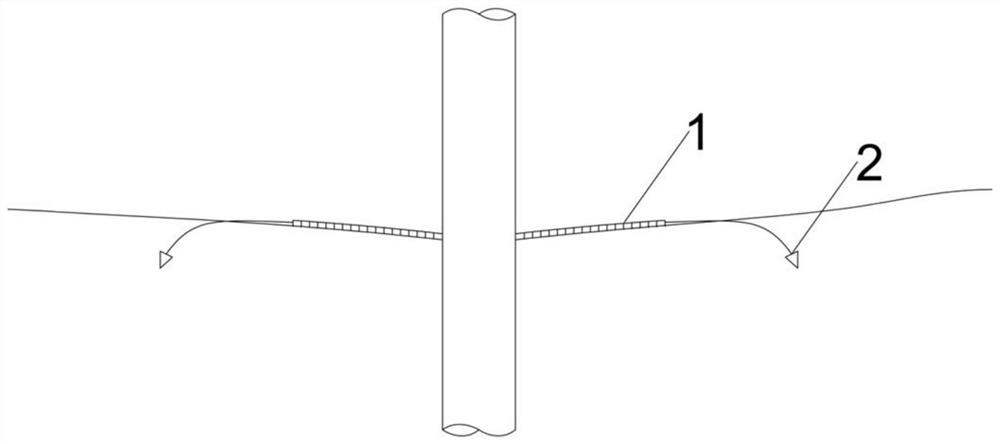

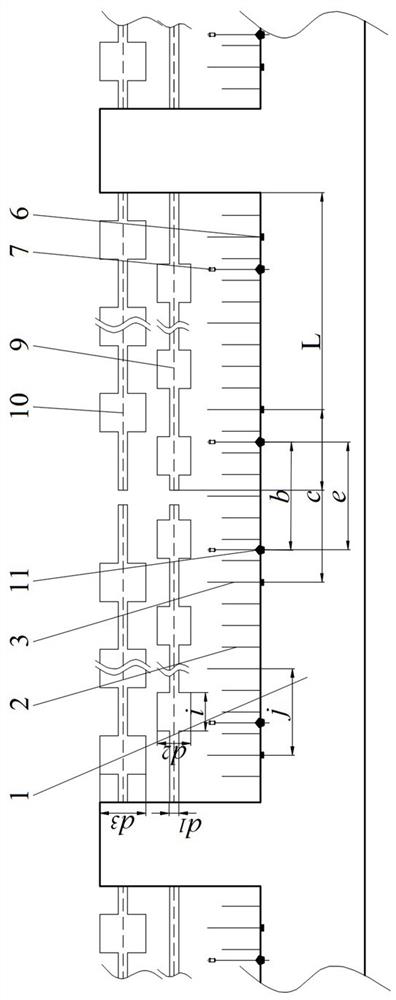

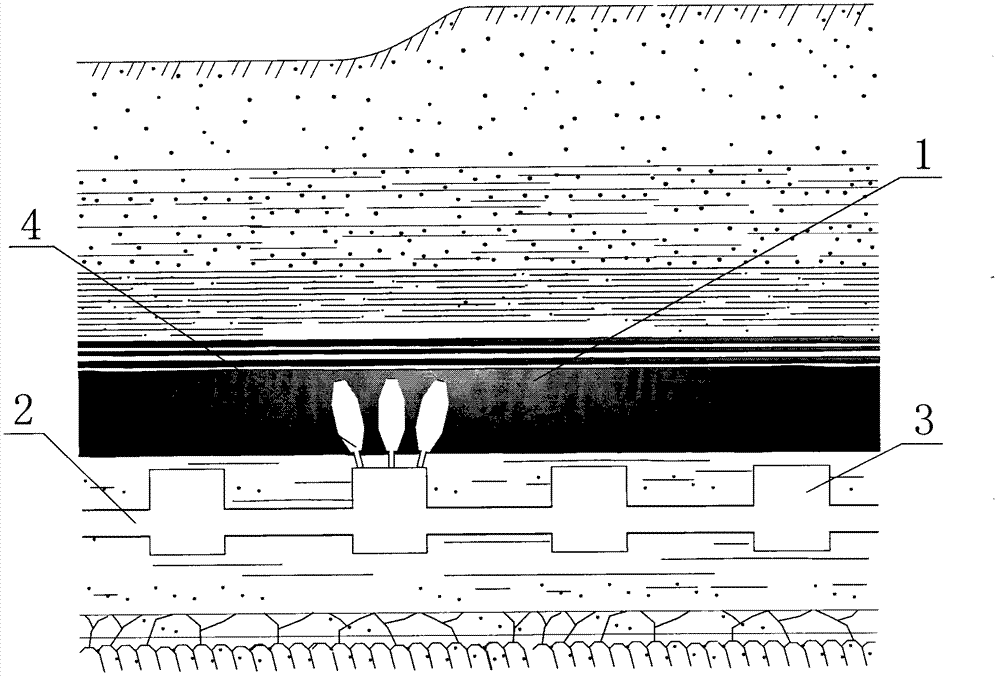

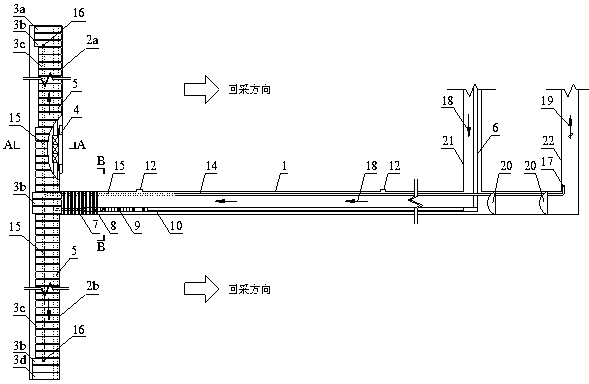

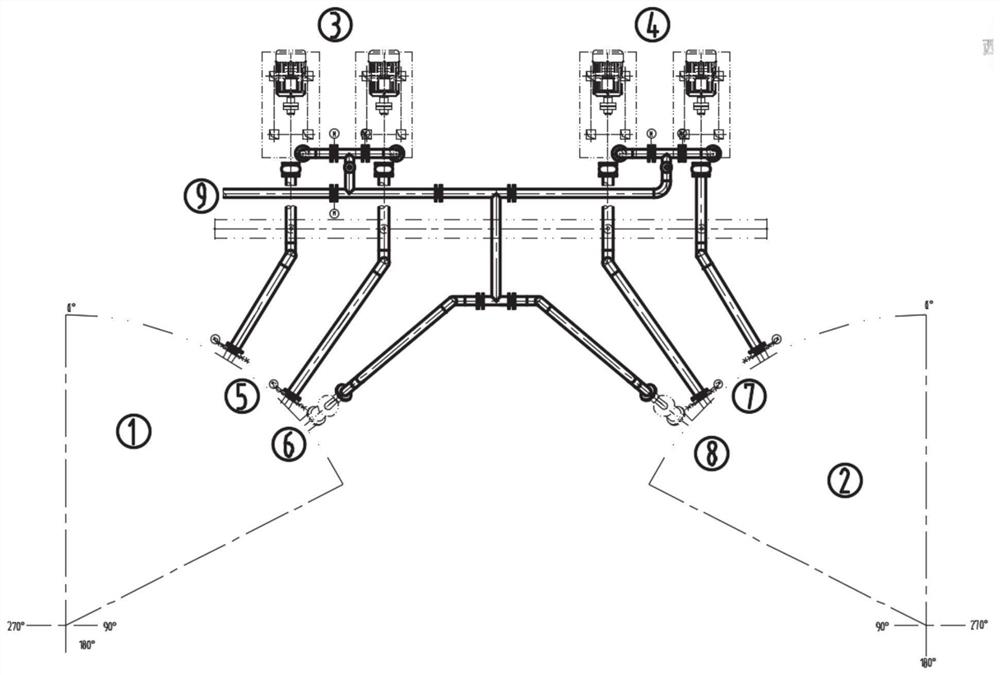

Coal Mining Method Without Coal Pillar and Gobside Entry in the Whole Underground Section

ActiveCN104975857BSimplified Arrangement SystemReduce the amount of maintenance workUnderground miningSurface miningSingle foldFresh air

The invention discloses a full well work area section non-pillar goaf-side-drift-free coal mining method, which comprises the following steps of: performing section transportation drift and coal mining working face digging to form a single-folding-corner two-section roadway; installing a leakage type air supply passage at the section transportation drift and the coal mining working face to convey fresh air flow to the single-folding-corner two-section roadway; using the single-folding-corner two-section roadway as an air return passage to combine the single-folding-corner two-section roadway and the leakage type air supply passage into a ventilation system of the roadway, wherein no section isolation pillar and no goaf-side drift exist in the layout of the single-folding-corner two-section roadway. The method has the advantages that the arrangement of the roadway is reasonable and simple; the roadway digging and maintenance workload is reduced; the cost of roadway digging equipment, surrounding rock support, salaries and the like is reduced; the surrounding rock support problem caused by the goaf-side drift is avoided; and the extraction rate on coal resources is improved, so that the air quantity distribution in the roadway is reasonable.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

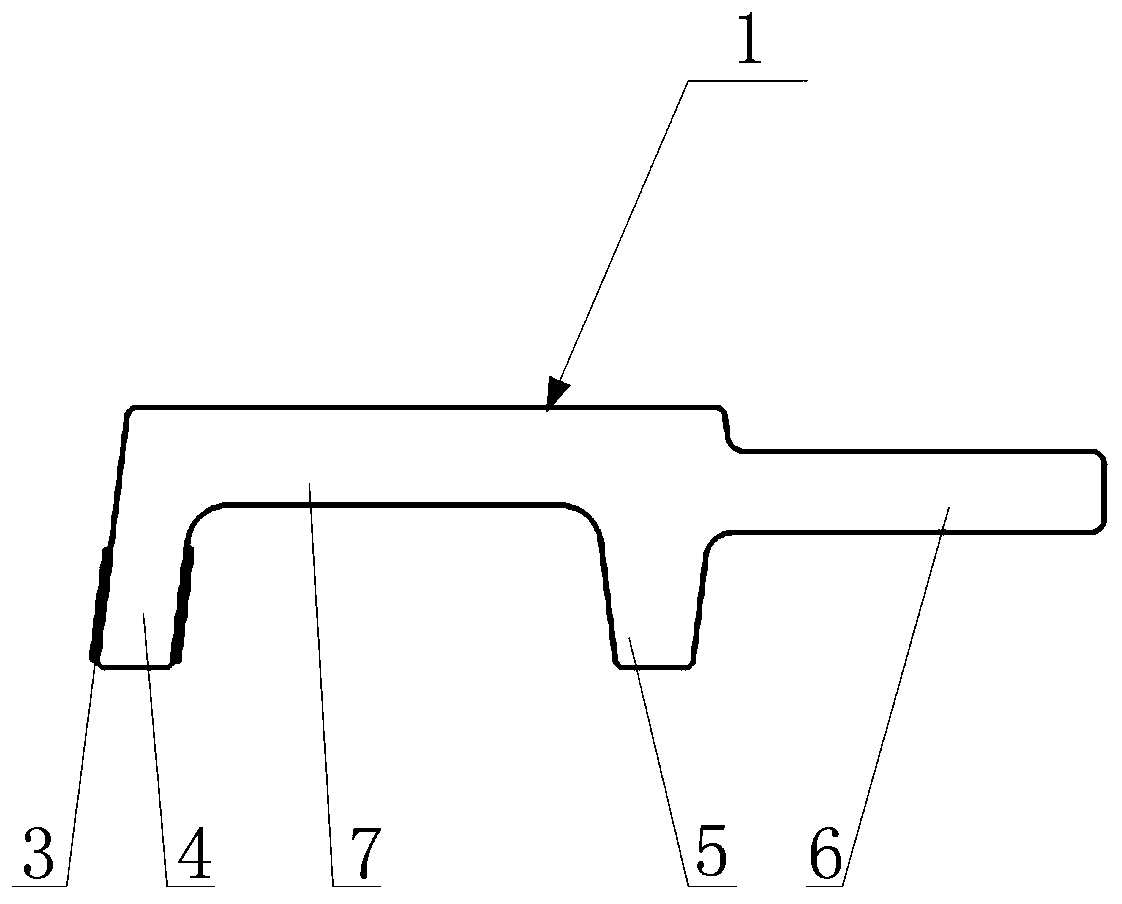

F-shaped steel rail with wear-resistant layer

InactiveCN110373963AImprove wear resistanceExtended maintenance cycleRailway tracksWear resistantEngineering

The invention discloses an F-shaped steel rail with a wear-resistant layer. The F-shaped steel rail with the wear-resistant layer is used for a rail row of a maglev train and comprises a steel rail body, wherein the steel rail body comprises a first protruding part, a second protruding part and a connecting part used for being connected with a sleeper, the first protruding part is far away from the connecting part than the second protruding part, and the side wall of the first protruding part is provided with the wear-resistant layer. Due to the fact that the wear-resistant layer is arranged in places with serious wear, such as the braking surface, the wear-resistant performance of the F-shaped steel rail can be greatly improved, the maintenance period and the service life of the steel rail are prolonged, the F-shaped steel rail is more wear-resistant, and the maintenance engineering quantity and cost are reduced.

Owner:BEIJING ENTERPRISES HLDG MAGLEV TECH DEV

A pressure relief and monitoring method for continuous large deformation of coal sides in deep roadways

ActiveCN111365077BChange stress stateReduce stressMining devicesUnderground miningMining engineeringDeformation monitoring

The invention discloses a pressure relief and monitoring method for continuous large deformation of coal sides in deep roadways. It is mainly aimed at continuous large deformation of the two sides of deep roadways and damage to the support system, which has to be continuously expanded and repaired to ensure roadway functions and maintenance costs. A substantial increase. The method of the present invention is to arrange large-scale pressure relief holes parallel to the axial direction of the roadway in the deep area of the two sides of the roadway, so that the deformation energy of the surrounding rock can be partially released and the peak value of the supporting stress of the two sides can be greatly transferred to the deep part. The space movement of the roadway provides a large compensation space; the pressure relief holes are arranged on both sides of the roadway to drill holes in different numbers and methods, and holes with different diameters are realized by means of radial hydraulic jet or mechanical reaming. The force and deformation monitoring system is installed on the two sides of the roadway. When the force and deformation increase, that is, the hole group is closed, the pressure relief hole group is implemented again to realize the long-term effective monitoring and control of the surrounding rock in the deep coal roadway, which greatly reduces the roadway maintenance. Work volume and cost.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

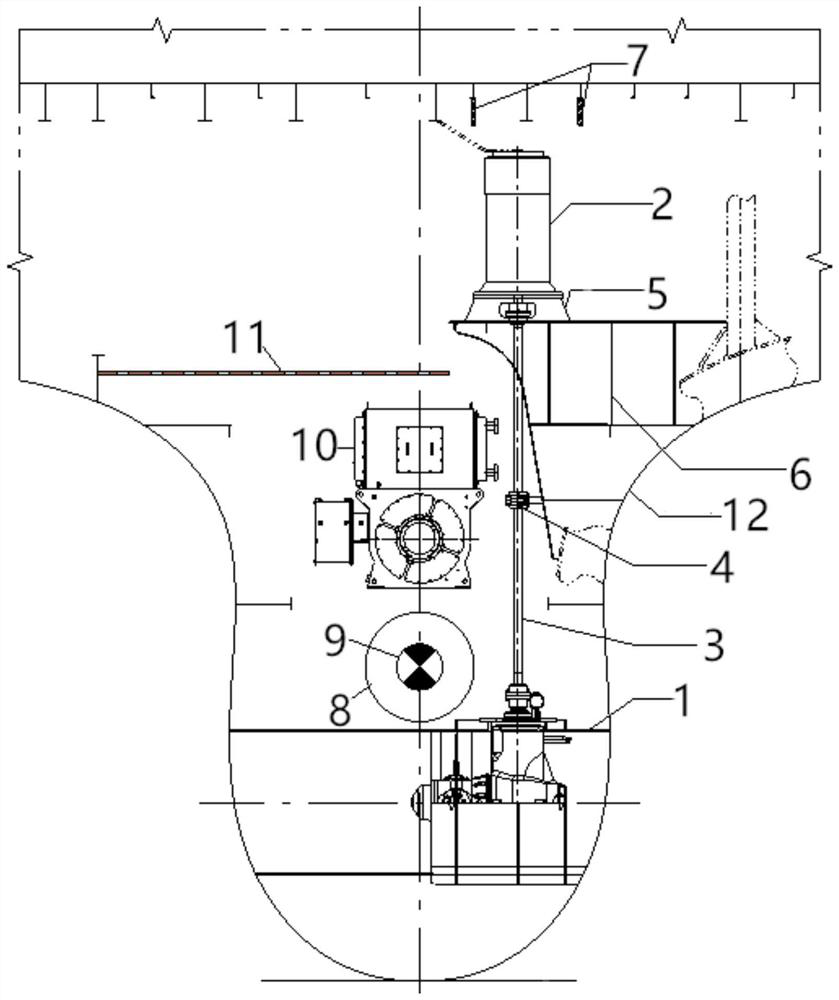

Ship stern thrust arrangement structure

PendingCN112278219AAvoid confictEasy maintenancePropulsion power plantsPropulsive elementsDrive shaftElectric machinery

The invention discloses a ship tail side thrust arrangement structure which comprises a drive motor and a tail side thrust body, the installation position of the drive motor is higher than that of a shaft generator, the output end of the drive motor is in transmission connection with a drive shaft extending downwards, and the lower end of the drive shaft is in transmission connection with the tailside thrust body. The split type design and supply are adopted between the tail side pushing body and the driving motor, the tail side pushing body and the driving motor are installed in a separatedmode and connected through the driving shaft, a tail shaft area with narrow space and numerous devices is avoided, conflict between the tail side pushing body and other devices is avoided, and optimalarrangement of the devices in the tail shaft area is facilitated.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

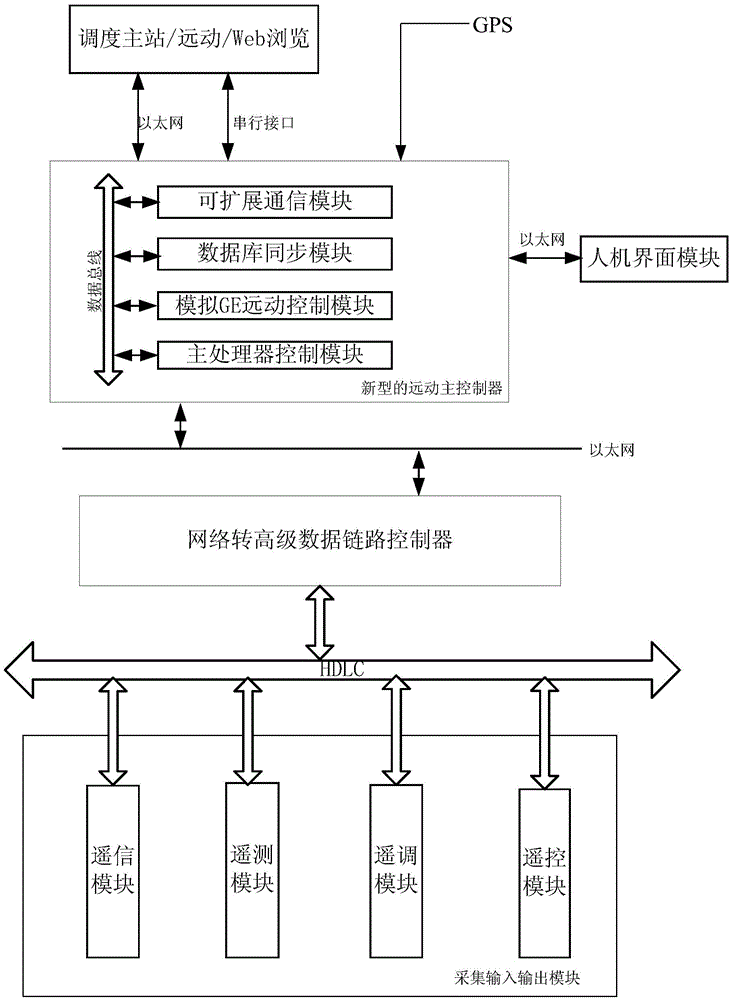

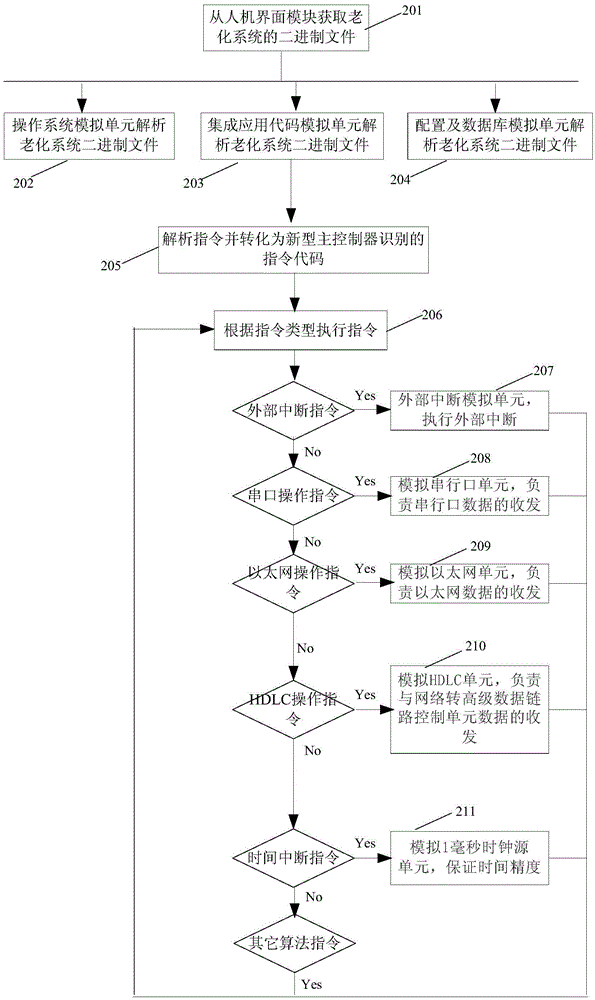

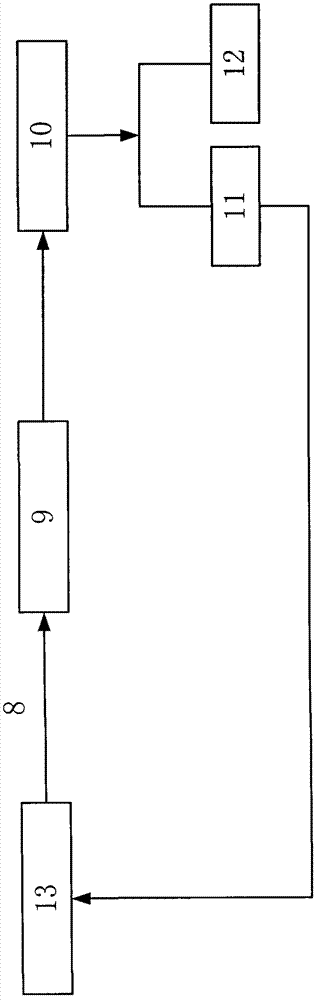

A simulation system for replacing ge remote control device

ActiveCN103941682BImprove securityReduce on-site commissioningProgramme total factory controlHuman–machine interfaceHigh-Level Data Link Control

The invention discloses a simulation system used for replacing a GE remote control device. The simulation system used for replacing the GE remote control device comprises a novel main remote controller, a human-computer interface module, a network conversion advanced data link controller and an input and output module for acquisition, wherein the input and output module for acquisition is connected with the network conversion advanced data link controller through an HDLC bus, the network conversion advanced data link controller is connected with the novel main remote controller through an Ethernet cable, and the novel main remote controller is connected with the human-computer interface module through an Ethernet cable. According to the simulation system used for replacing the GE remote control device, the network conversion advanced data link controller is additionally arranged in the system, an original GE remote control device module is simulated in the novel main remote controller, in this way, a plug-and-play replacement system is obtained, the field debugging workload and the maintenance workload are relieved, the construction cost, the installation space and the number of dispatching channel are all reduced, and the safety of network data is improved; the number of cooperation manufacturers is reduced, debugging difficulty is lowered, and installation time is shortened.

Owner:上海惠安系统控制有限公司

Integrated multi-flow-state odorless domestic sewage treatment equipment

PendingCN111453939AGood processing effectSmall footprintSpecific water treatment objectivesWater contaminantsSewage treatmentWater treatment

The invention provides integrated multi-flow-state odorless domestic sewage treatment equipment, and belongs to the technical field of sewage treatment. The integrated multi-flow-state odorless domestic sewage treatment equipment comprises a shell, a biochemical treatment area, a denitrification filtering area, an equipment operation chamber and a biological deodorization area, wherein the biochemical treatment area, the denitrification filtering area, the equipment operation chamber and the biological deodorization area are arranged in the shell, the biochemical treatment area is connected with the denitrification filtering area, and the equipment operation chamber is connected with the denitrification filtering area and the biological deodorization area. The integrated multi-flow-state odorless domestic sewage treatment equipment disclosed by the invention has the characteristics of odorless operation, good treatment effect, small occupied area, simplicity and convenience in field installation, convenience in later-period operation management, basically no secondary pollution and the like.

Owner:中建生态环境集团有限公司

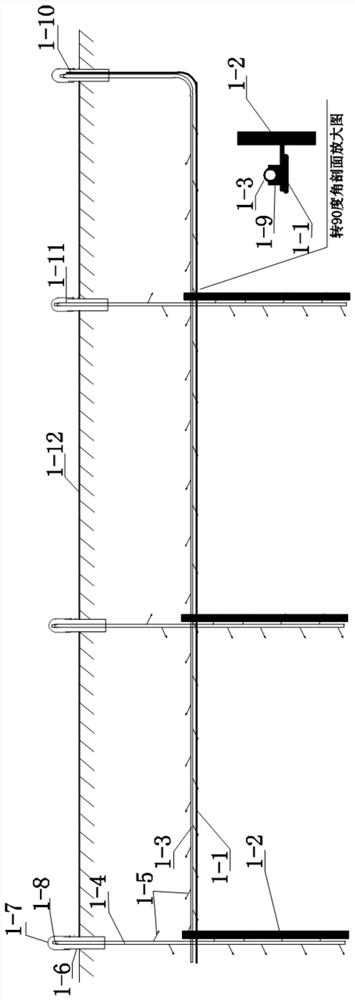

Lightning protection and grounding construction method for sustainable maintenance without secondary trenching

ActiveCN110277661BLow costReduce construction costsLine/current collector detailsExcavationsArchitectural engineeringConstruction design

Owner:张昱 +1

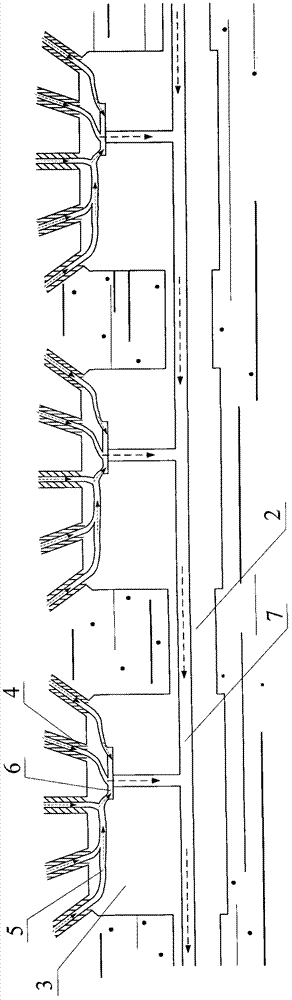

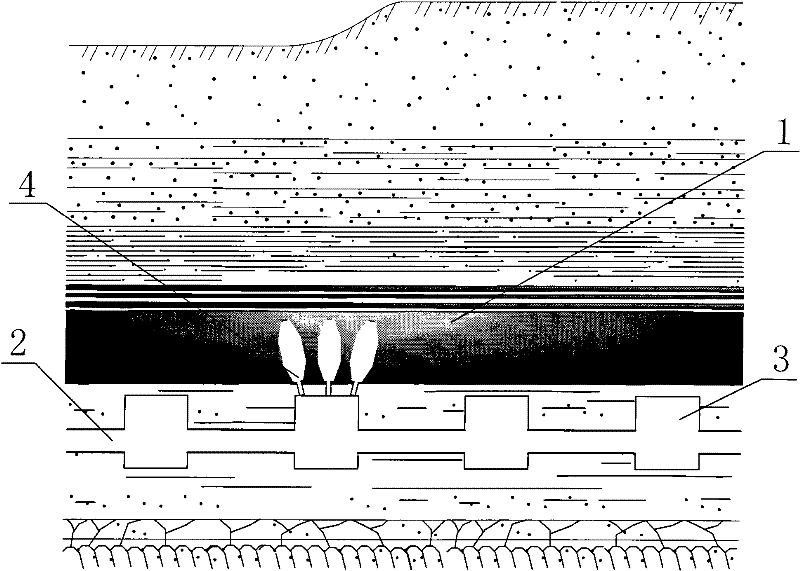

Method for mining coalbed methane through regional underground high-pressure hydraulic drilling and pressure relief

The invention discloses a method for mining coalbed methane through regional underground high-pressure hydraulic drilling and pressure relief, which comprises the following steps: putting a jet device, a filtering device and a drill stem connected with the filtering device into a drill hole (4); starting a high-pressure pump; carrying out rotating impact drilling on the wall of the drill hole (4) of a coalbed (1) by using the jet device so as to form a pressure relief space; and after the drilling operation meets the design requirements, carrying out coalbed methane drainage operation on the coalbed (1) subjected to drilling according to the conventional method, and then, emitting the obtained coalbed methane by a coalbed drainage pipe (7). A coal-water mixture (8) produced in the process of drilling operation (13) is fed into a swirler (10) so as to realize the separation of coal and water, and the obtained liquid supernatant (11) is directly recycled in the drilling operation (13). By using the method disclosed by the invention, the number of drill holes (3) can be greatly reduced, the pressure relief space (6) of the protruded coalbed (1) can be expanded, and the coalbed methane drainage efficiency can be improved; and meanwhile, the injection of high pressure water can effectively suppress dust, thereby reducing the risk of the protruded coalbed and improving the underground operating environment.

Owner:ZHENGZHOU UNIV

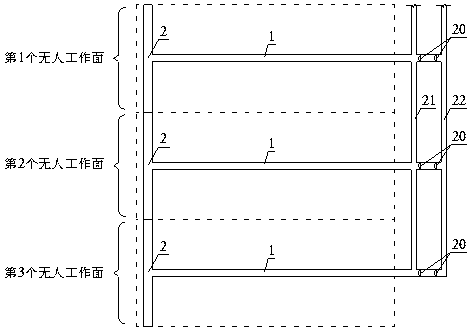

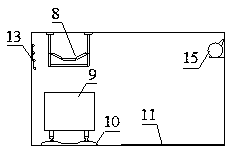

A t-shaped roadway layout suitable for intelligent unmanned working face

ActiveCN108979658BReduce the amount of maintenance workTake advantage ofTunnel/mines ventillationTunnelsTransit systemMechanical engineering

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Regional gas underground high-pressure jet hole digging, pressure relief and outburst prevention method

InactiveCN102022133BIncrease the exposed areaImprove breathabilityFluid removalGas removalWater flowEngineering

Owner:ZHENGZHOU UNIV

Combustion-supporting air conduit and stainless steel hood-type annealing furnace with same

ActiveCN104726685AExtended service lifeReduce the amount of maintenance workBell type furnacesHeat treatment furnacesCombustionMaterials science

The invention discloses a combustion-supporting air conduit and a stainless steel hood-type annealing furnace with the same. The combustion-supporting air conduit disclosed by the invention is characterized by comprising an upper combustion-supporting air conduit, a lower combustion-supporting air conduit, an upper combustion-supporting air conduit sleeve and a lower combustion-supporting air conduit sleeve, wherein one end of the lower combustion-supporting air conduit sleeve is hermetically connected with one end of the lower combustion-supporting air conduit; the other end of the lower combustion-supporting air conduit sleeve is nested with one end of the upper combustion-supporting air conduit; on end of the upper combustion-supporting air conduit sleeve is hermetically connected with one end of the upper combustion-supporting air conduit; the other end of the upper combustion-supporting air conduit sleeve is hermetically connected with the outer wall of the lower combustion-supporting air conduit sleeve; and free extension of one end of the upper combustion-supporting air conduit and one end of the lower combustion-supporting air conduit caused by combustion-supporting air is not affected by length setting of the upper combustion-supporting air conduit sleeve and the lower combustion-supporting air conduit sleeve.

Owner:NINGBO BAOXIN STAINLESS STEEL

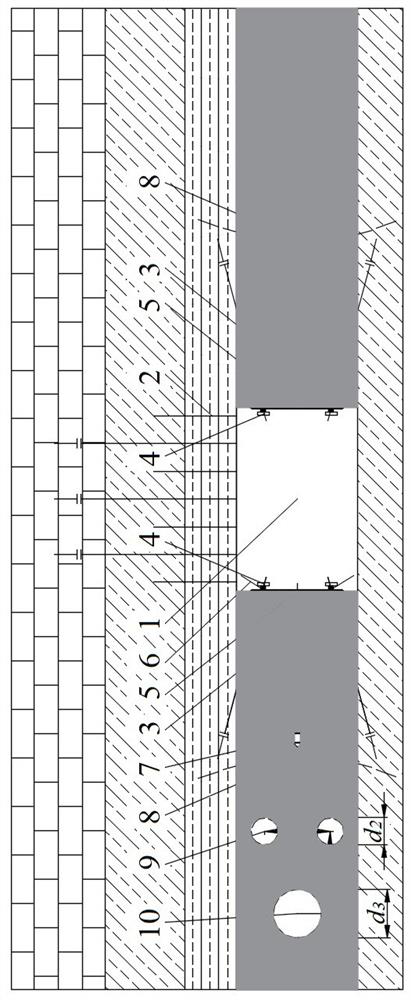

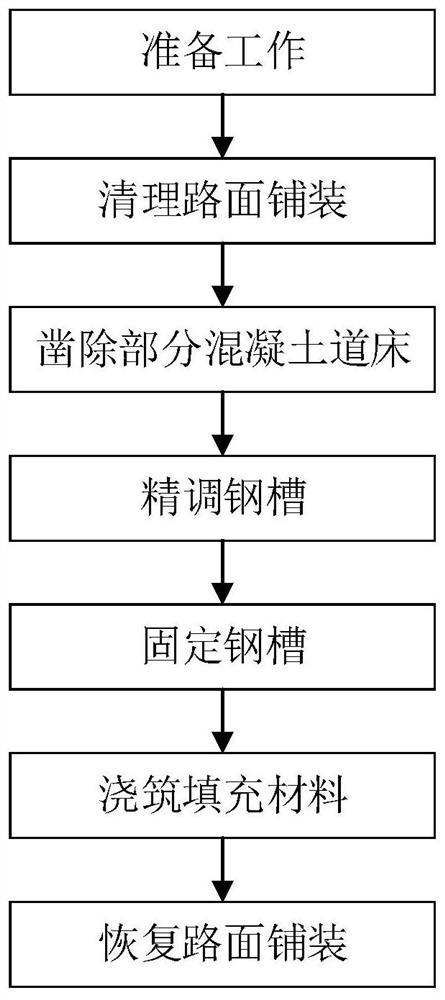

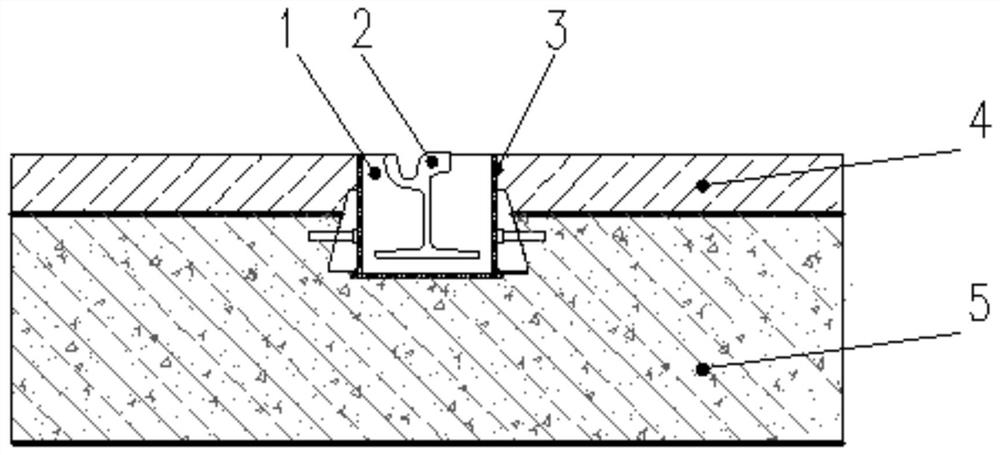

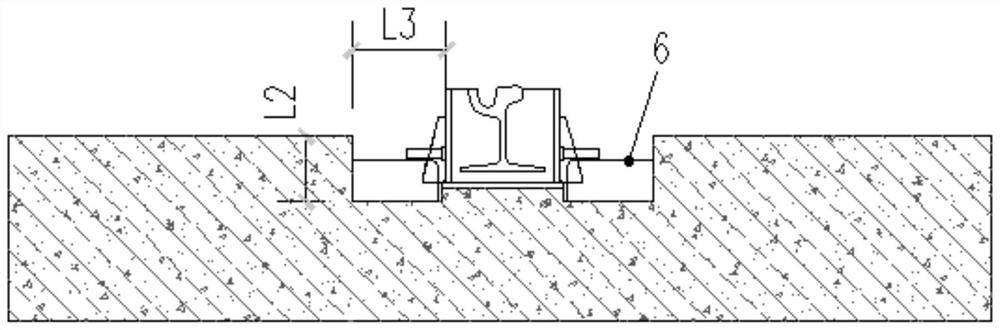

A Maintenance Method for Uneven Settlement of Embedded Track Steel Channel Ballast Subgrade

ActiveCN111074703BAvoid damageGuaranteed integrityTrack maintainenceArchitectural engineeringEngineering

The invention discloses a maintenance method for the uneven settlement of embedded track steel channel type roadbed, comprising: step 1: preparation work; step 2: cleaning road surface pavement; step 3: chiseling away the concrete ballast bed on both sides of the steel channel; Step 4: Fine adjustment of the steel channel: Cut the ballast bed reinforcement connected to the steel channel, use the steel channel connection device, the reaction frame and the jack to lift the steel channel; place the height-adjusting pad on the bottom of the steel channel and adjust the tooling to complete Steel channel geometry adjustment; Step 5: Fixing the steel channel: planting steel bars at a distance in the ballast bed on both sides of the steel channel, and fixing the implanted steel bars with the steel channel; Step 6: Pouring filling materials; Step 7: Restoring Paving. The present invention realizes rail precision restoration by finely adjusting the steel groove, has large adjustment amount and low operation difficulty, minimizes damage to the ballast bed, greatly reduces maintenance engineering quantity, and shortens maintenance period. This method is also applicable to the reconstruction of existing lines with embedded tracks.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

Method for improving metallurgy solution crystallization deposition in air cooling course and air cooling column

InactiveCN101498557BImproved crystalline depositionImprove operational efficiencyCellsTrickle coolersCooling towerUltrasonic radiation

The invention relates to an air cooling tower and a method for improving the crystallization and the sedimentation of metallurgical solution during air cooling process. Metallurgical solution cooled by the air cooling tower is conveyed to the inner upper part of the air cooling tower by a conveyer and then downwards flows along the surface of the inner wall of a tower cylinder to form a liquid film covering the surface of the inner wall of the tower cylinder so that temperature reducing droplets sprayed to the inner wall of the tower cylinder fall into the liquid film on the surface of the inner wall of the tower cylinder but not directly fall to the surface of the tower cylinder so as to prevent droplets from crystallizing and being sedimentated on the inner wall of the tower cylinder; meanwhile, ultrasonic radiation can also be carried out on metallurgical solution cooled by the air cooling tower to refine crystal grains in the air-cooled metallurgical solution; the treated metallurgical solution is conveyed to the inner upper part of air cooling tower and downwards flows along the surface of the inner wall of the tower cylinder to form a liquid film with refined crystal grains, and the liquid film is covered on the surface of the inner wall of the tower cylinder to prevent crystal grains in the liquid film from being sedimentated on the surface of the inner wall of the tower cylinder.

Owner:佛山市兴民科技有限公司

Electric power telemechanical device RTU and method for implementing automatic voltage control of generating plant

InactiveCN101299587BEnsure consistencyGuaranteed operating accuracyComputer controlSingle network parallel feeding arrangementsAutomatic controlPower station

The invention discloses an electric power telemechanical apparatus RTU and a method for realizing the automatic voltage control of the power plant. The inventive electric power telemechanical apparatus includes a central control module, a remote signalling module, a telemetering module, a remote regulating module and a remote control module, wherein the central control module includes a communication submodule, a data bank submodule and an automatic voltage control submodule, which generates the control signal for adjusting the wattless production output of the generating set, based on the data stored in the data bank submodule, and transmits the control signals to the remote regulating module or the remote control module through the communication submodule, then transmits to the generating set which participates in the voltage control through the remote regulating module or the remote control module, realizes the automatic voltage control. The invention gives full play to the function of the electric power telemechanical apparatus, reduces the amount of the situ hardware units, increases the operational precision of the data in the AVC adjusting process.

Owner:上海惠安系统控制有限公司

A double-tower double-circulation desulfurization system and method that cancels the accident slurry system

ActiveCN112058028BSmall amount of workReduce corrosionGas treatmentDispersed particle separationProcess engineeringSlurry

The disclosure provides a double-tower double-circulation desulfurization system and method that cancels the accident slurry system, including: a primary absorption tower and a secondary absorption tower, the primary absorption tower is connected to the gypsum discharge pump of the primary tower through the first pipeline, and the secondary absorption tower The first-stage absorption tower is connected to the second-stage gypsum discharge pump through the second pipeline; the first-stage tower gypsum discharge pump and the second-stage gypsum discharge pump are both connected to the desulfurization system through the third pipeline; The first-level absorption tower is connected to the second-level absorption tower; the design of the accident slurry system is canceled, which effectively avoids the extension of the construction period caused by the construction of a separate configuration of the accident slurry system, and reduces the increase in construction on site while ensuring the construction period and project quality , making the regional planning of wet desulfurization more standardized, and the fire maintenance road smoother; reducing the corrosion, scaling, and maintenance workload in the desulfurization system, reducing the maintenance workload of equipment, and reducing the energy consumption of the desulfurization system.

Owner:SHANDONG GUOSHUN CONSTR GRP

On-line pouring molding method for burner nozzle of heating furnace

The invention discloses an online pouring molding method for the burner nozzle of a heating furnace. Firstly, the nozzle mold on the burner brick is made, and the nozzle mold is set at the position of the burner on the furnace wall during maintenance, and then the burner nozzle of the regenerator is installed. The damaged furnace wall and the surrounding area are poured with corundum mullite casting material, and at the same time, the closing part of the top and the tail is closed with high alumina bricks, and the partition plate in the heat storage box is covered with formwork. Make repairs. Finally, after the poured slurry is solidified and meets the strength standard requirements, the nozzle mold on the burner brick is removed, and the burner nozzle is formed. In the case of damage to the burner of the heating furnace, based on the requirement that the nozzle of the burner brick remains unchanged, the present invention firstly makes a mold according to the size of the nozzle of the burner, and then repairs it by casting the nozzle with a refractory material. The burner repaired by the invention is not easy to deform and collapse, effectively prolongs the service life of the burner on the heating furnace, and further shortens the construction time and maintenance engineering amount.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com