Coal Mining Method Without Coal Pillar and Gobside Entry in the Whole Underground Section

A coal mining method and a technology without coal pillars, which are applied in ground mining, earthwork drilling, underground mining, etc., can solve problems such as easy roof collapse of the roadway surrounding rock, large loss of coal, and difficulty in roadway support. The effect of reducing the amount of excavation and maintenance, reducing the consumption of wind power, and improving the recovery rate of coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

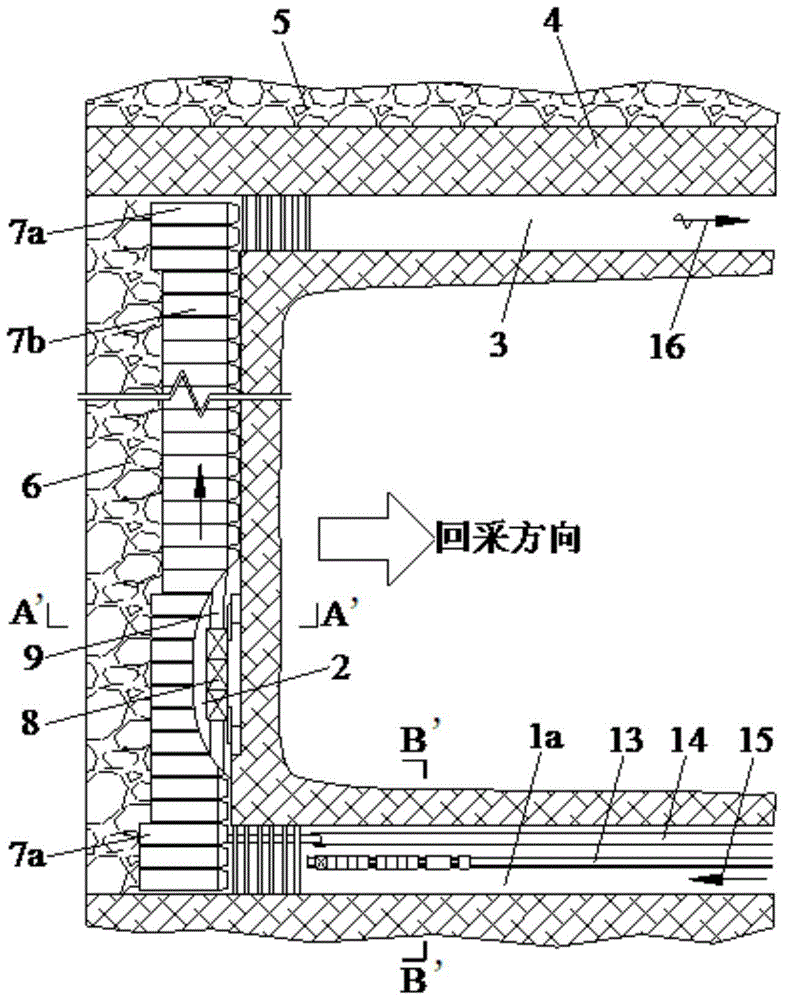

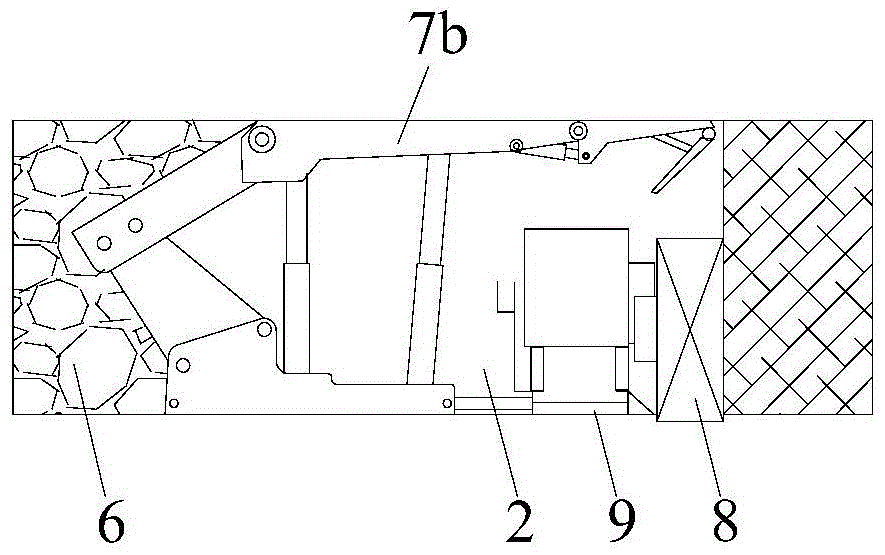

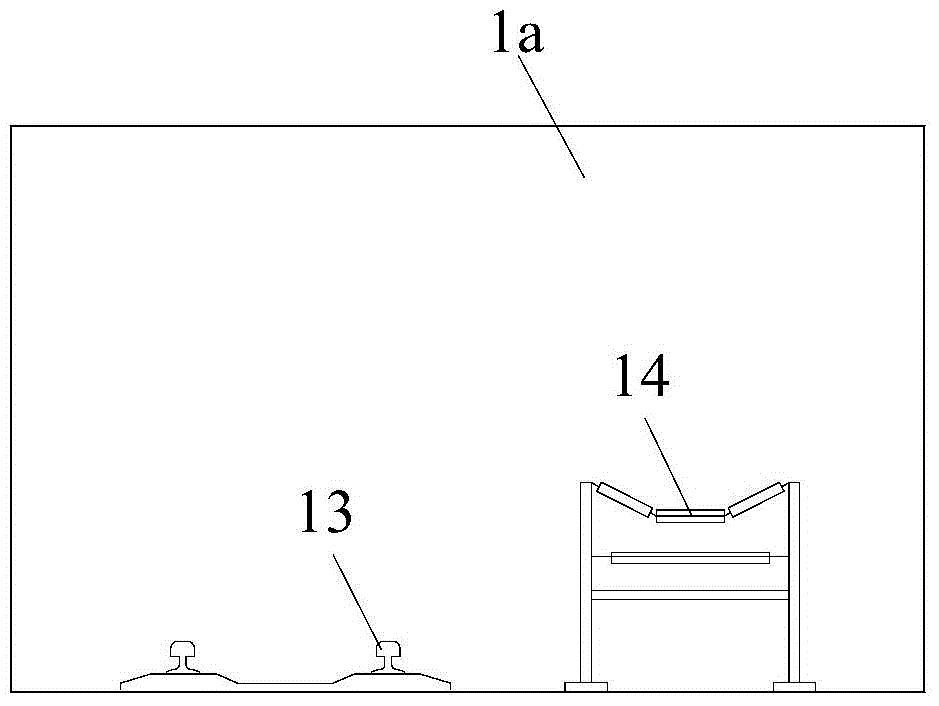

[0044] like Figure 4 As shown, it is a layout diagram of the coal mining method without coal pillars and gob-side entry in the whole underground section provided by the present invention. It can be seen from the figure that the coal mining roadway of the present invention has a two-stage roadway with a single knuckle.

[0045] Specifically, such as Figure 4~6 As shown, the coal mining method of the present invention includes a single-corner two-section roadway that is only composed of the section transportation entryway 1b and the coal mining face 2, wherein the front end of the section transportation entryway 1b and the mining face The lower end of the coal face 2 is connected to form a single knuckle, while the upper end of the coal mining face 2 extends to the coal-rock boundary area at the edge of the goaf in the adjacent section, that is, the layout of the single knuckle two-section roadway has no Sectional isolation of coal pillars and gob-side entry. In addition to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com