A pressure relief and monitoring method for continuous large deformation of coal sides in deep roadways

A technology of large deformation and roadway, which is used in earth-moving drilling, ground mining, mining equipment and other directions, can solve the problems of large deformation of coal gang, and achieve the effect of reducing engineering volume and cost, realizing monitoring and control, and ensuring normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

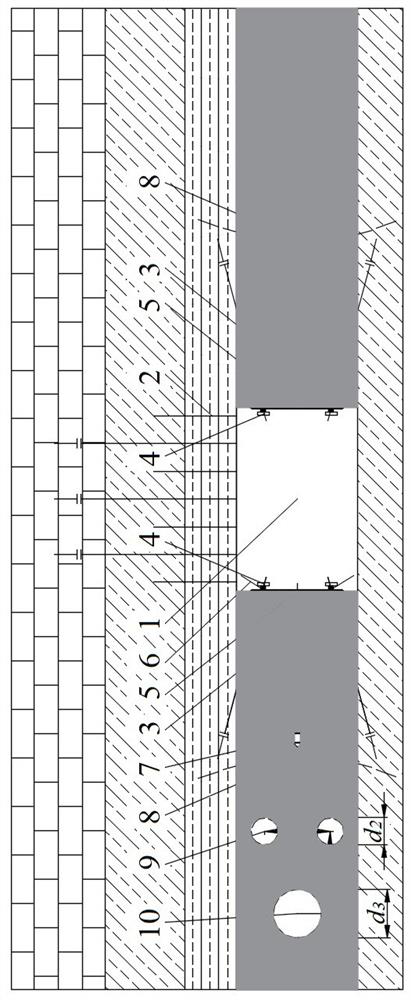

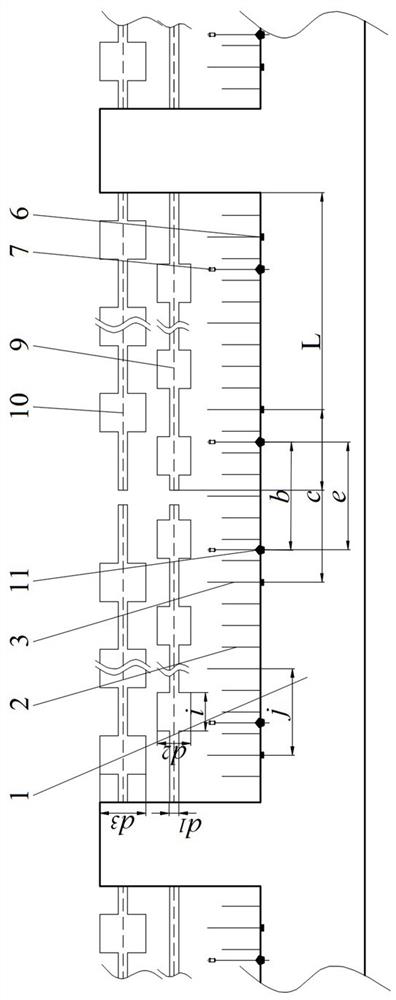

[0059] A continuous large deformation of coal walls in deep roadways Utilizes a pressure relief and monitoring method for continuous large deformation of coal walls in deep roadways according to the present invention, such as figure 1 , 2 As shown, the long-term effective monitoring and control of surrounding rock in deep coal roadway is realized.

[0060] The specific implementation methods and steps are:

[0061] (1) Step 1: Install the borehole stress gauge 7 on a vertical coal wall in the deep roadway, and the length of the installed borehole stress gauge 7 is a , the distance between the borehole stress gauges 7 is b , the borehole stress gauge 7 covers the entire deep roadway 1, and a borehole stress monitoring system is constructed through a plurality of borehole stress gauges 7 to effectively monitor the stress state of the roadway anchorage boundary 8 for a long time. The length of the borehole stress gauge 7 is a 5m, drilling stress gauge 7 spacing b 60m;

[00...

Embodiment 2

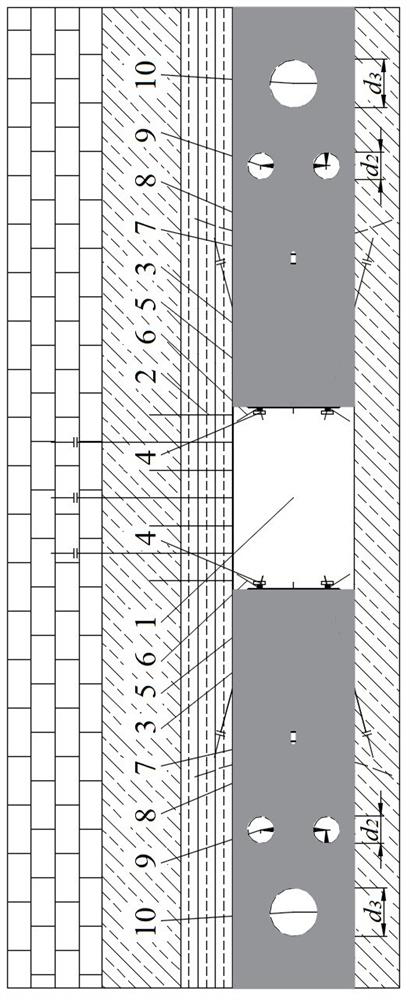

[0067] The continuous large deformation of the two sides of the coal wall in a deep roadway utilizes a pressure relief and monitoring method for the continuous large deformation of the deep roadway coal side of the present invention, such as image 3 , 4 As shown, the long-term effective monitoring and control of surrounding rock in deep coal roadway is realized.

[0068] By comparing the diagrams of Example 1 and Example 2, it can be seen that the arrangement of the pressure relief hole groups in Example 2 and Example 1 is an isosceles triangle arrangement, and the pressure relief holes 10 with large diameter interval differences are located at small diameter interval differences. On the outside of the pressure relief holes 10, the pressure relief holes 10 with large diameter intervals and differences are located at the top corners. The difference between the two is that in embodiment 2, large pressure relief hole groups are arranged on both sides of the roadway side, and it...

Embodiment 3

[0070] A continuous large deformation of coal walls in deep roadways Utilizes a pressure relief and monitoring method for continuous large deformation of coal walls in deep roadways according to the present invention, such as Figure 5 , 6 As shown, the long-term effective monitoring and control of surrounding rock in deep coal roadway is realized.

[0071] The specific implementation methods and steps are:

[0072] (1) Step 1: Install the borehole stress gauge 7 on a vertical coal wall in the deep roadway, and the length of the installed borehole stress gauge 7 is a , the distance between the borehole stress gauges 7 is b , the borehole stress gauge 7 covers the entire deep roadway 1, and a borehole stress monitoring system is constructed through a plurality of borehole stress gauges 7 to effectively monitor the stress state of the roadway anchorage boundary 8 for a long time. The length of the borehole stress gauge 7 is a 5m, drilling stress gauge 7 spacing b 60m;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com