High-speed particle impact test apparatus

A technology of impact testing and high-speed particles, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem that the quality of glasses, goggles, and masks cannot be reliably guaranteed, and the impact speed cannot meet the standard requirements and cannot meet the standard requirements, etc. problems, to achieve the effect of reliable impact measurement results, low manufacturing cost, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

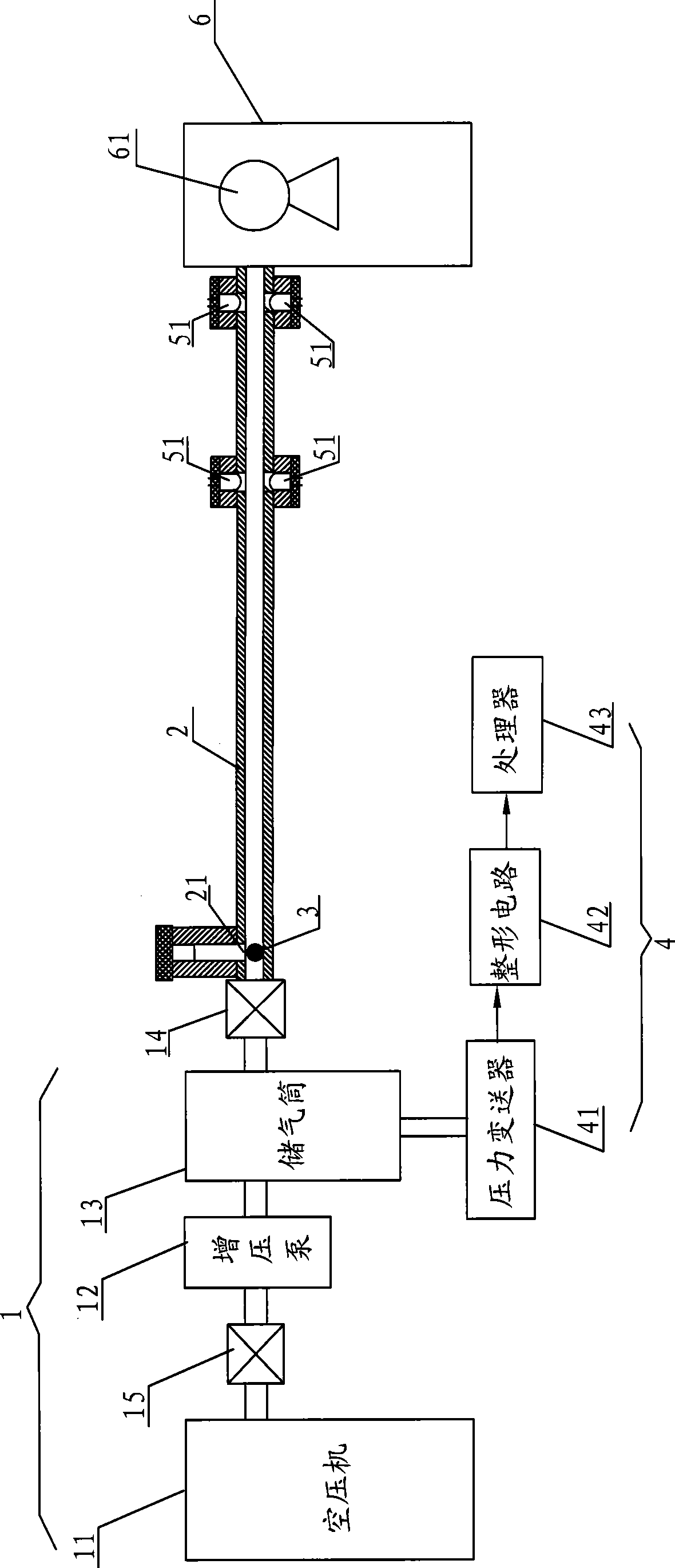

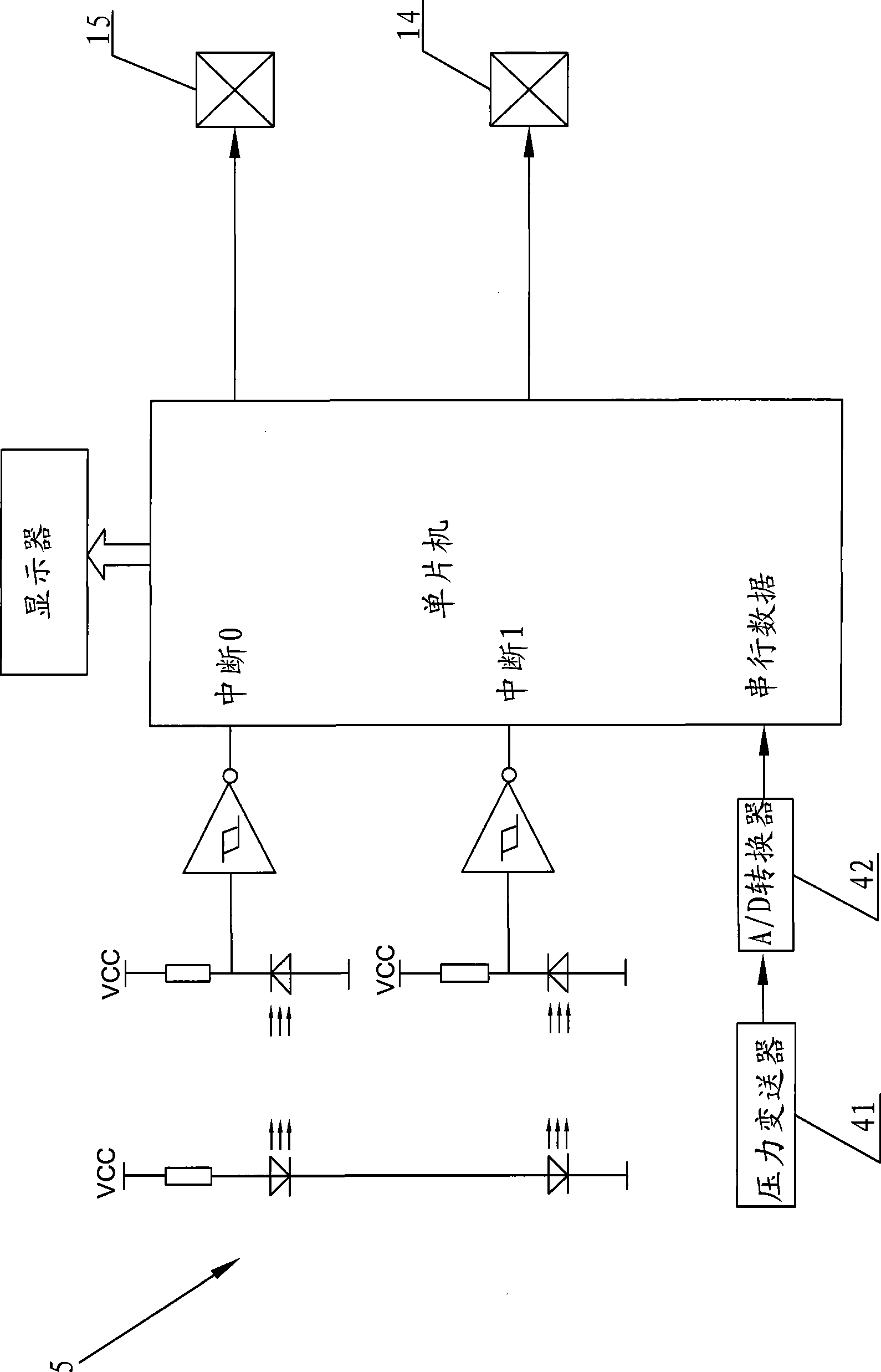

[0022] Such as figure 1 and figure 2 As shown, the high-speed particle impact test device of the present invention includes two parts, one is a mechanical part, and the other is an electric control part. The mechanical part is mainly composed of a pressure excitation unit 1, a guide tube 2 and a particle 3. To generate the high-voltage driving force that drives the particles to move at high speed in the guide tube 2; the electronic control part is mainly formed by a core processor and peripheral circuit units, and the cooperative work of the electronic control part and the mechanical part realizes the high-voltage value of the pressure excitation unit 1 To measure and measure the impact velocity of particles 3, each functional unit is now explained one by one:

[0023] The pressure excitation unit 1 includes an air compressor 11, a booster p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com