Blade edge breakage monitoring device of aerogenerator

A wind turbine and monitoring device technology, which is applied to wind turbine components, wind engine monitoring, wind engines, etc., can solve the problems of unreliable reliability, time-consuming and laborious operation, and low efficiency, and achieve good real-time performance and reduce Small loss of power generation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

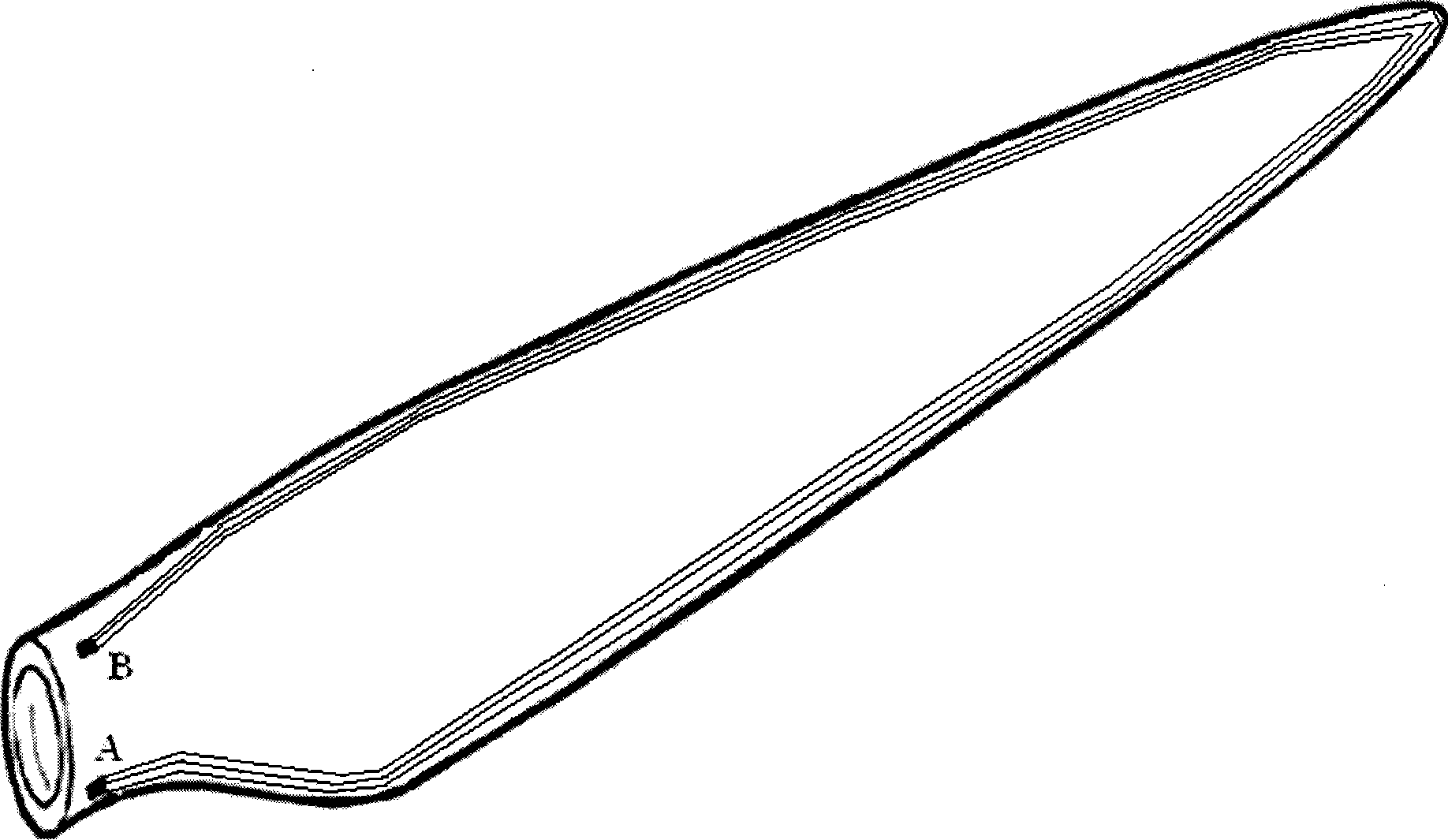

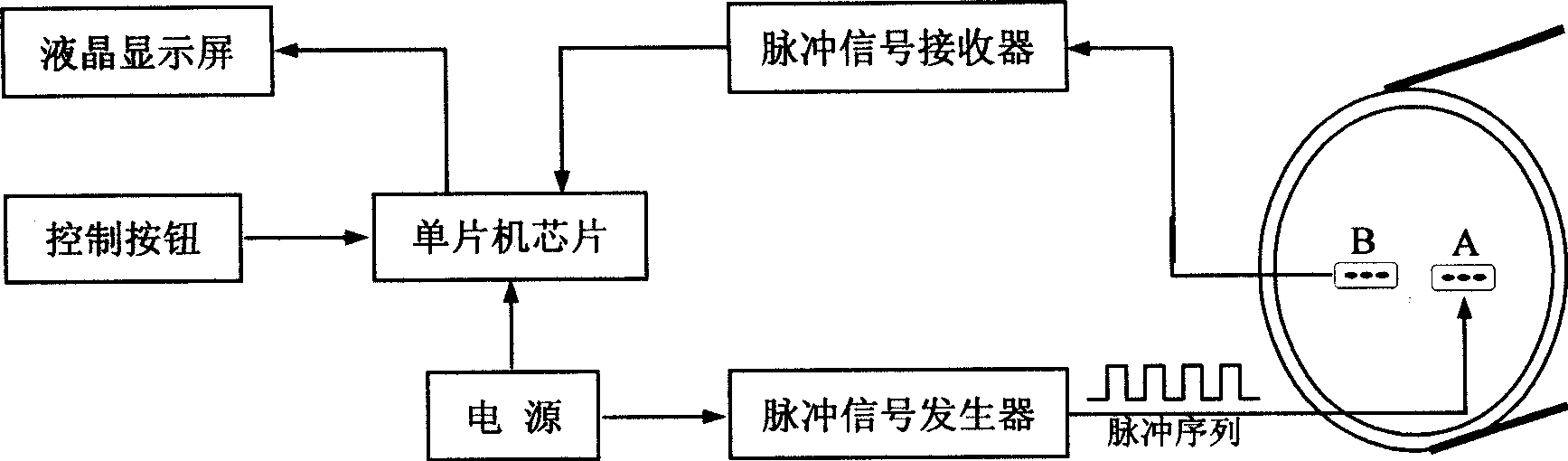

[0017] Such as figure 1 and figure 2 As shown, three optical fibers are implanted inside the fan blade according to the pre-calculated and designed blade edge loss contour trend. Each level of optical fiber enters from its own inlet port A, and the outlet port B is led out to form a conduction loop.

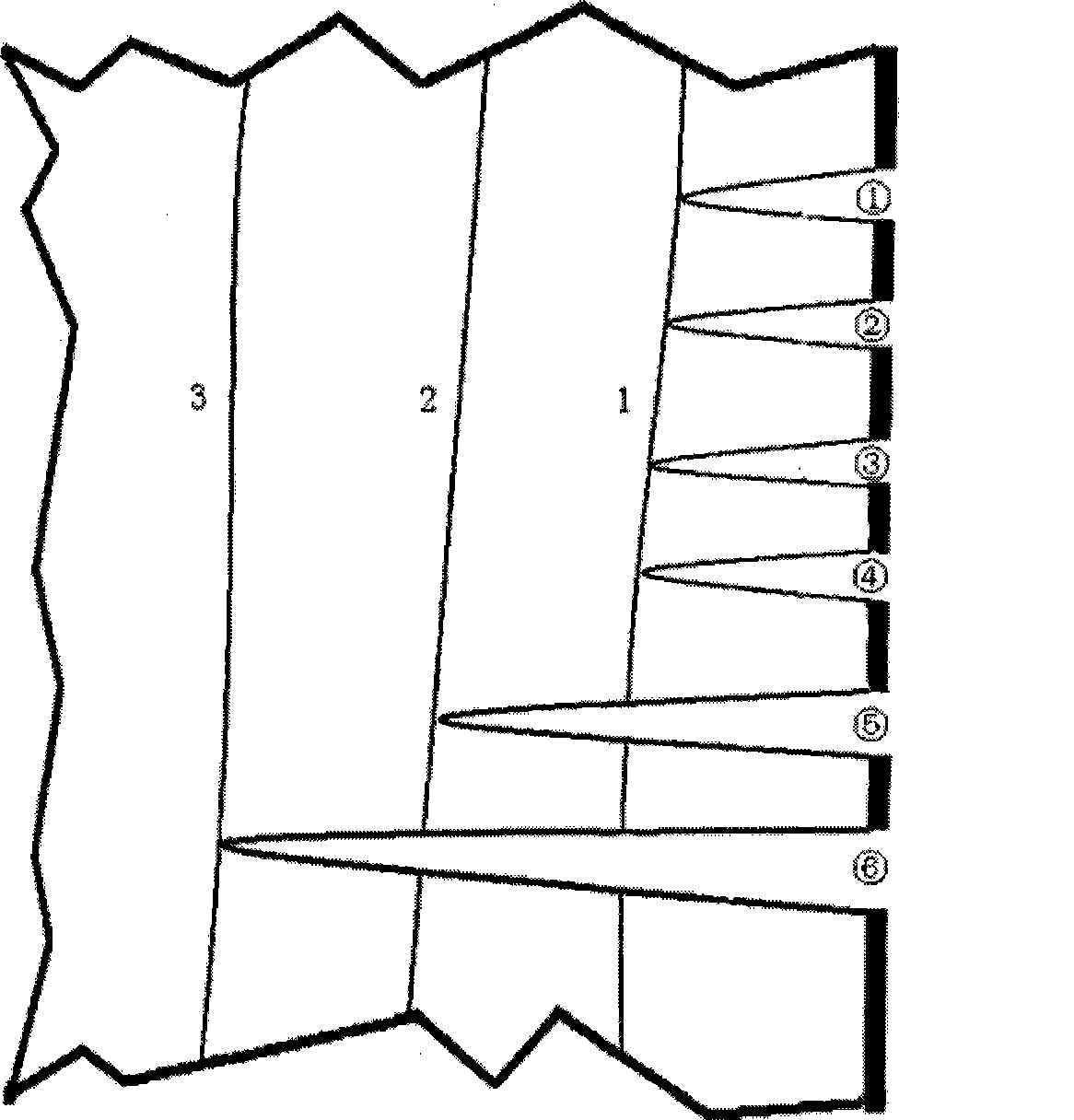

[0018] Such as figure 2 As shown, the interval of different loss levels at the edge of the blade is the blade damage contour line, that is, the apex of the blade edge loss depression corresponding to the same failure risk level after the failure risk level is determined through stress analysis and load calculation.

[0019] Among them, the contour line 1 is based on the loss point ①②③④ calculated by stress analysis when the edge of the blade is lost. In the case of a wind speed of 80 m / s, the blade may have a hidden danger of breaking, and all the loss points that meet this condition are smoothly connected. The drawn contour trend lines, contour line 2 and contour line 3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com