Optical fiber connector

A technology of optical fiber connectors and fiber grooves, which is applied in the coupling of optical waveguides, etc., to achieve the effects of simple structure, reliable connection, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

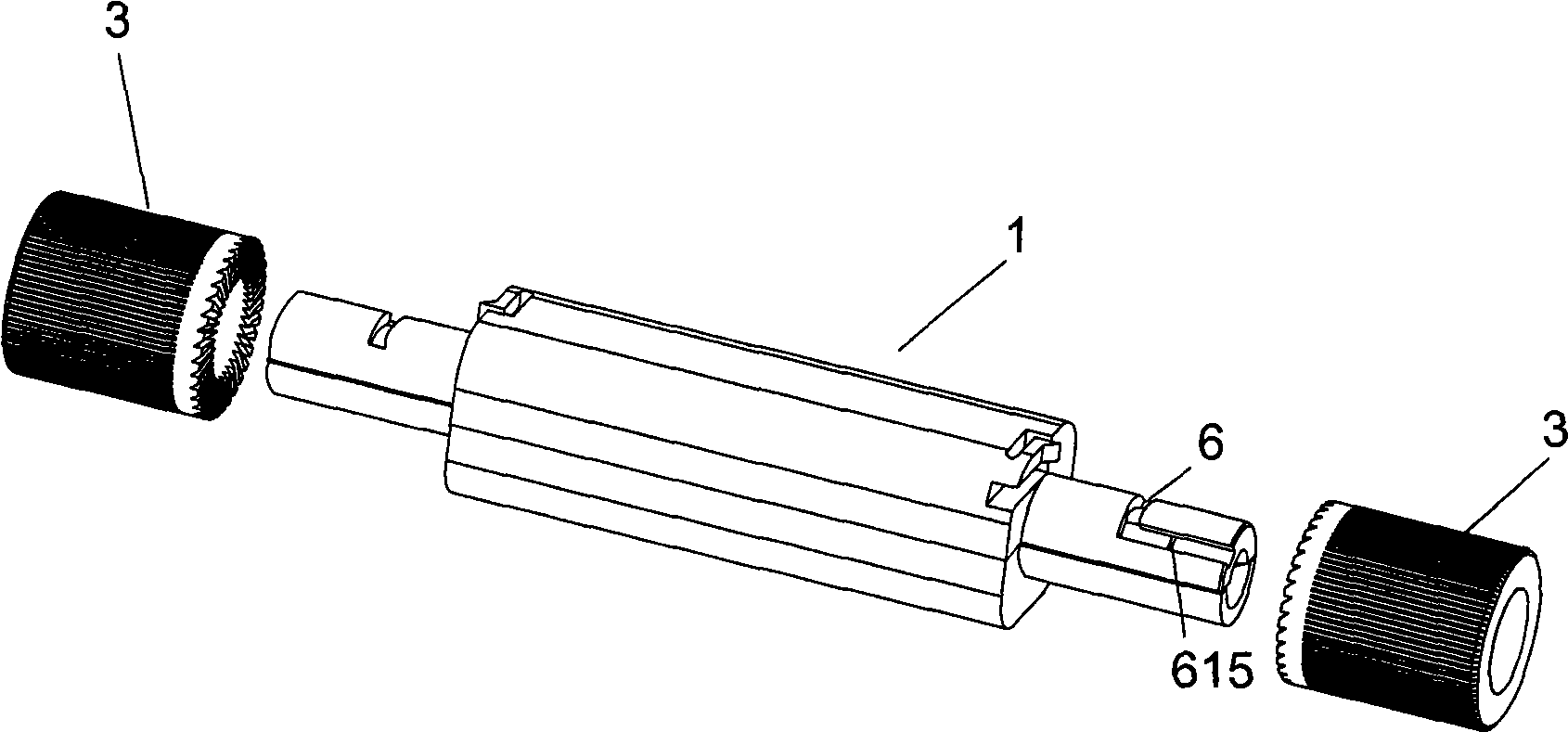

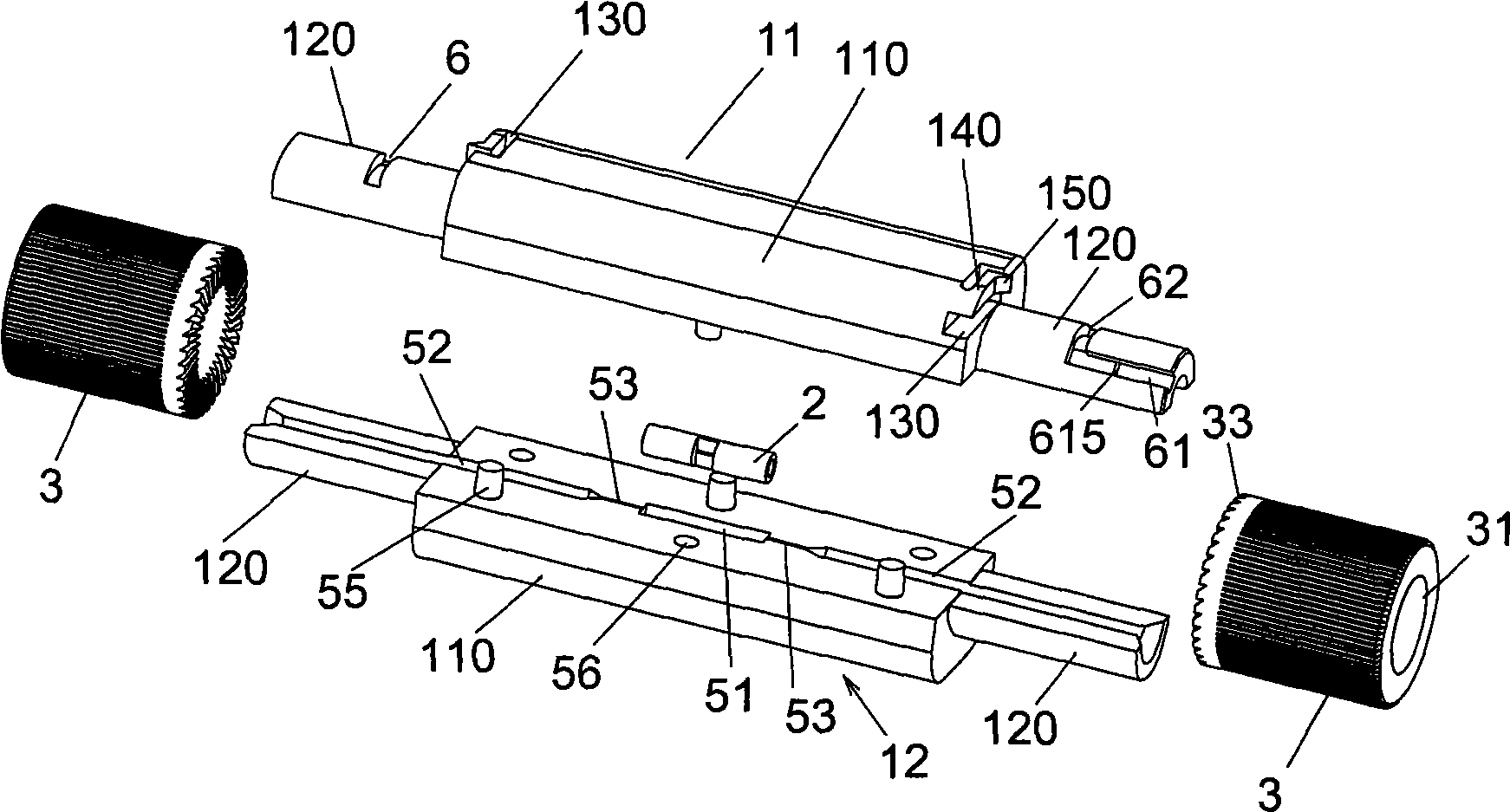

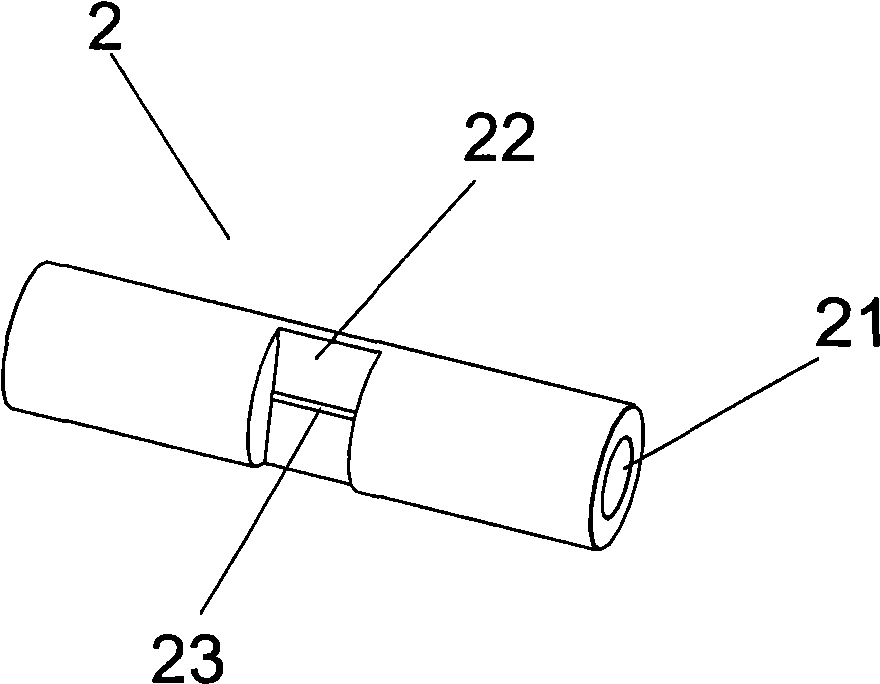

[0027] figure 1 and 2 The structure of the optical fiber splice according to the first embodiment of the present invention is shown. As shown in the figure, the optical fiber connector of the present invention includes a housing 1 , an optical fiber sleeve 2 and fixing sleeves 3 sleeved on both sides of the housing. The casing 1 includes an upper casing 11 and a lower casing 12, and the upper casing 11 and the lower casing 12 are superimposed on each other. The upper housing 11 and the lower housing 12 are symmetrically composed of a main body 110 and clamping parts 120 located on both sides of the main body 110, on the opposite sides of the main body 110 and the clamping part 120 of the upper and lower housings Fiber slots for accommodating optical fibers are arranged symmetrically. Figure 5 A schematic structural view of an optical fiber is shown, and the optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com