Combustion controller for stoker type incinerator

A control device and technology for incinerators, applied in incinerators, combustion methods, combustion types, etc., can solve problems such as undisclosed mixing ratio control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

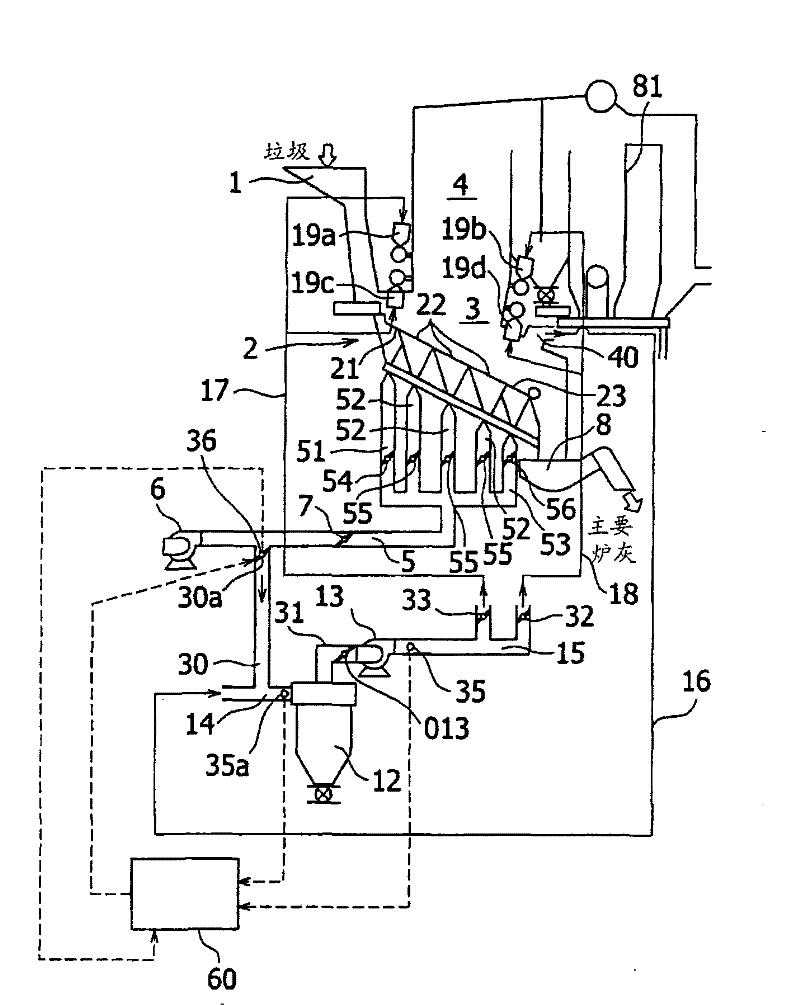

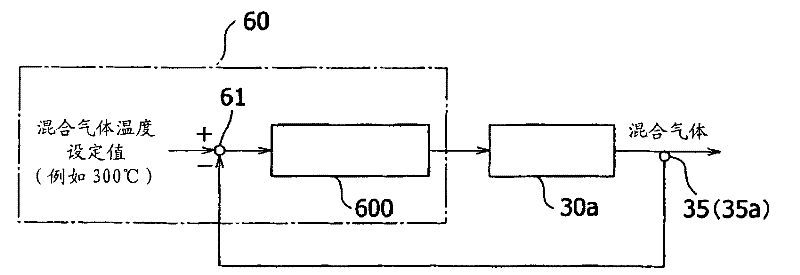

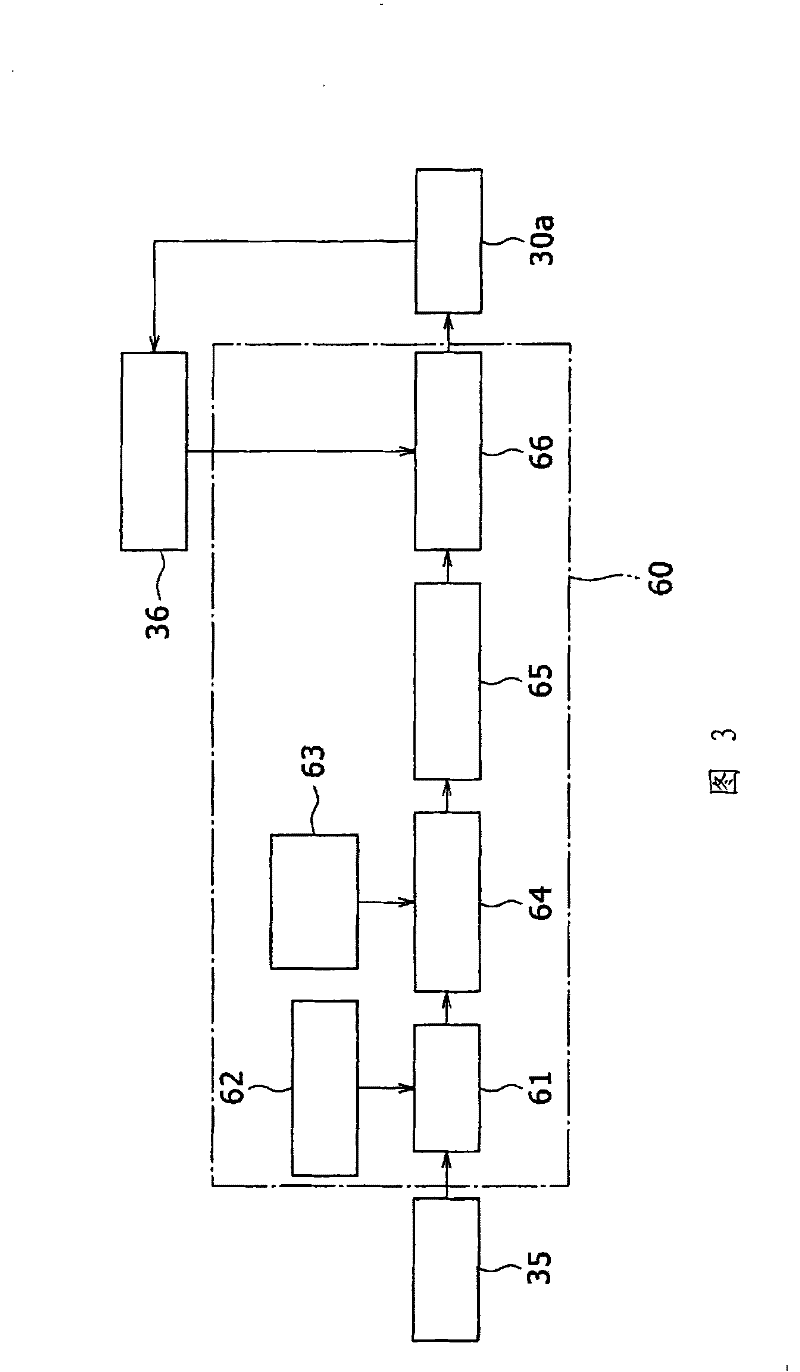

[0043] figure 1 It is a block diagram showing the charging type incinerator according to the first embodiment of the present invention, figure 2 is a schematic configuration diagram showing the combustion control device of the above-mentioned first embodiment, image 3 It is a combustion control block diagram of the above-mentioned first embodiment.

[0044] figure 1 In the figure, reference numeral 1 is a garbage hopper into which to-be-incinerated materials such as garbage and industrial waste are thrown, and reference numeral 2 is a charging type incinerator. The charging type incinerator 2 is laid with: a drying area feeder 21 mainly constituting the drying area at the bottom of the furnace from the input port of the garbage hopper 1, a main combustion area feeder 22 mainly constituting the combustion area, and an ember mainly constituting Ember combustion zone feeder 23 in the combustion zone. The feeder 21 in the drying zone is located on the most upstream side, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com