Spray irrigation equipment for row crop and arrangement mode of the spray irrigation equipment in field

A technology for crops and equipment, applied in the field of sprinkler irrigation equipment and water spray irrigation, can solve problems such as insufficient mobility, uneven spraying, inconvenient use, etc., to reduce food production costs, reduce the impact of wind force and wind direction, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

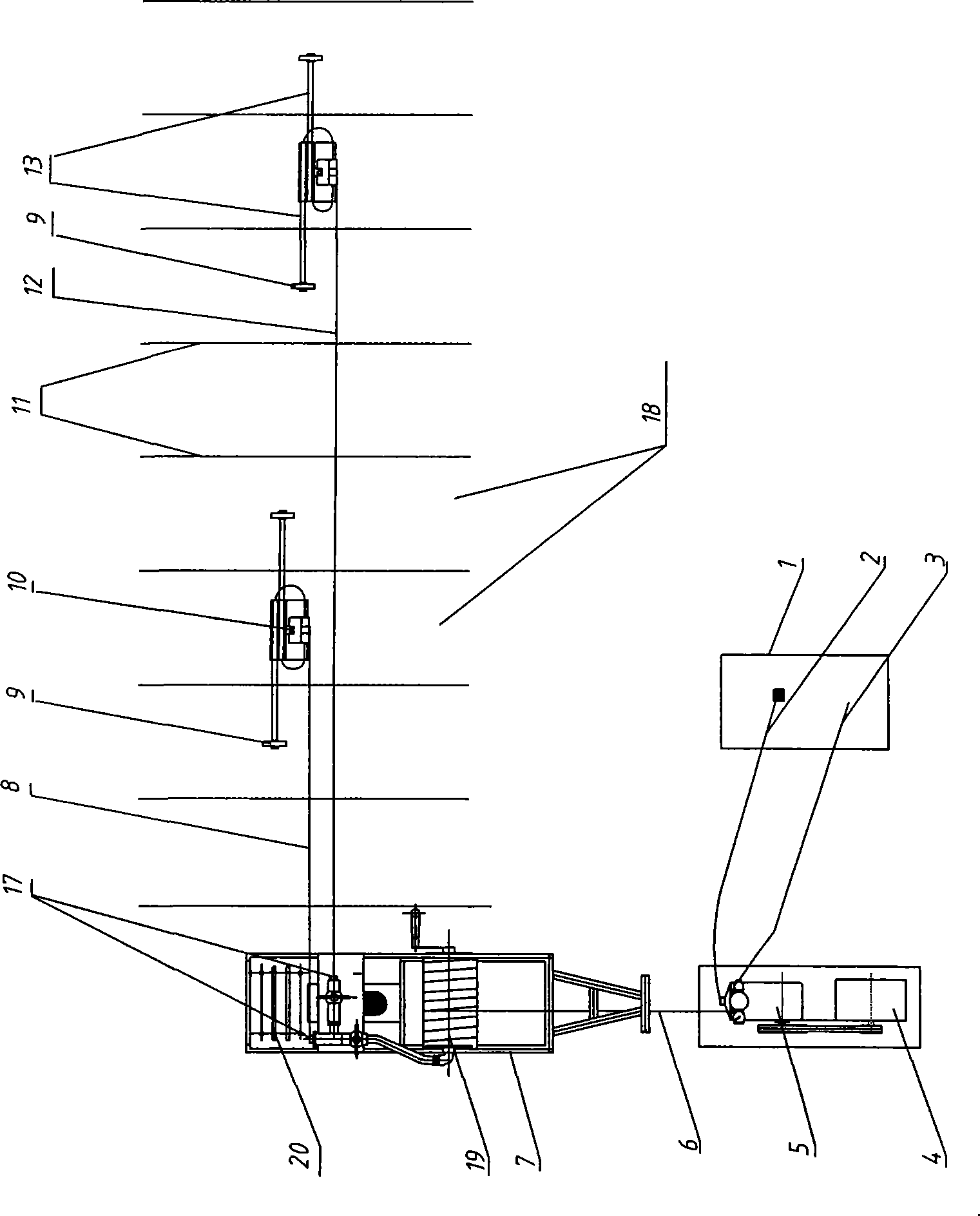

[0028] Embodiment 1 Water-powered strip sprinkler sprinkler combined sprinkler irrigation index field measurement test conditions: sprinkler irrigation time 10min, average wind speed 1.5-2.0m / s, nozzle pressure 0.25MPa, spray elevation angle 21°, blade inclination angle 43°, sprinkler installation height 0.4m, the spraying direction of the nozzle is parallel to the main wind direction, and the rotation of the impeller is consistent, so as to ensure that the spraying direction of the main branch flow remains unchanged during the test.

[0029] The field measurement test results of the sprinkler irrigation index of the hydraulic drive strip sprinkler show that the effective range of the Φ2.5mm single nozzle downwind side is 8m, the maximum range is 9.5m, the effective range of the upwind side is 6m, the maximum range is 7.5m, and the average sprinkler intensity of the downwind side of the single nozzle is 24.36mm / h, the average sprinkler irrigation intensity on the upwind side i...

Embodiment 2

[0031] Example 2 Spray irrigation time is 10 minutes, average wind speed is 1.5-2.0m / s, nozzle water pressure is 0.5MPa, spray elevation angle is 18°, blade inclination angle is 43°, nozzle installation height is 0.5m, nozzle spraying direction is parallel to main wind direction, and impeller turns in the same direction , to ensure that the injection direction of the main branch flow remains unchanged during the test. The diameter of the spray hole is 3.0mm, and the number of blades is 8. Test the irrigation indicators meet the standards.

Embodiment 3

[0032] Example 3 Spray irrigation time is 10 minutes, average wind speed is 1.5-2.0m / s, nozzle water pressure is 0.2MPa, spray elevation angle is 22°, blade inclination angle is 43°, nozzle installation height is 0.4m, nozzle spraying direction is parallel to main wind direction, and impeller rotation is consistent , to ensure that the injection direction of the main branch flow remains unchanged during the test. The diameter of the spray hole is 2.5mm, and the number of blades is 6. Test the irrigation indicators meet the standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com