High-efficiency evaporation type radiator

An evaporative cooling and high-efficiency technology, applied in the direction of heat exchanger types, indirect heat exchangers, fixed duct components, etc., can solve the problem of flushing finned tubes, low heat exchange efficiency of finned tubes, and restricting the cooling efficiency of evaporative coolers. and other problems, to achieve the effect of reducing air flow resistance, good air cooling effect, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

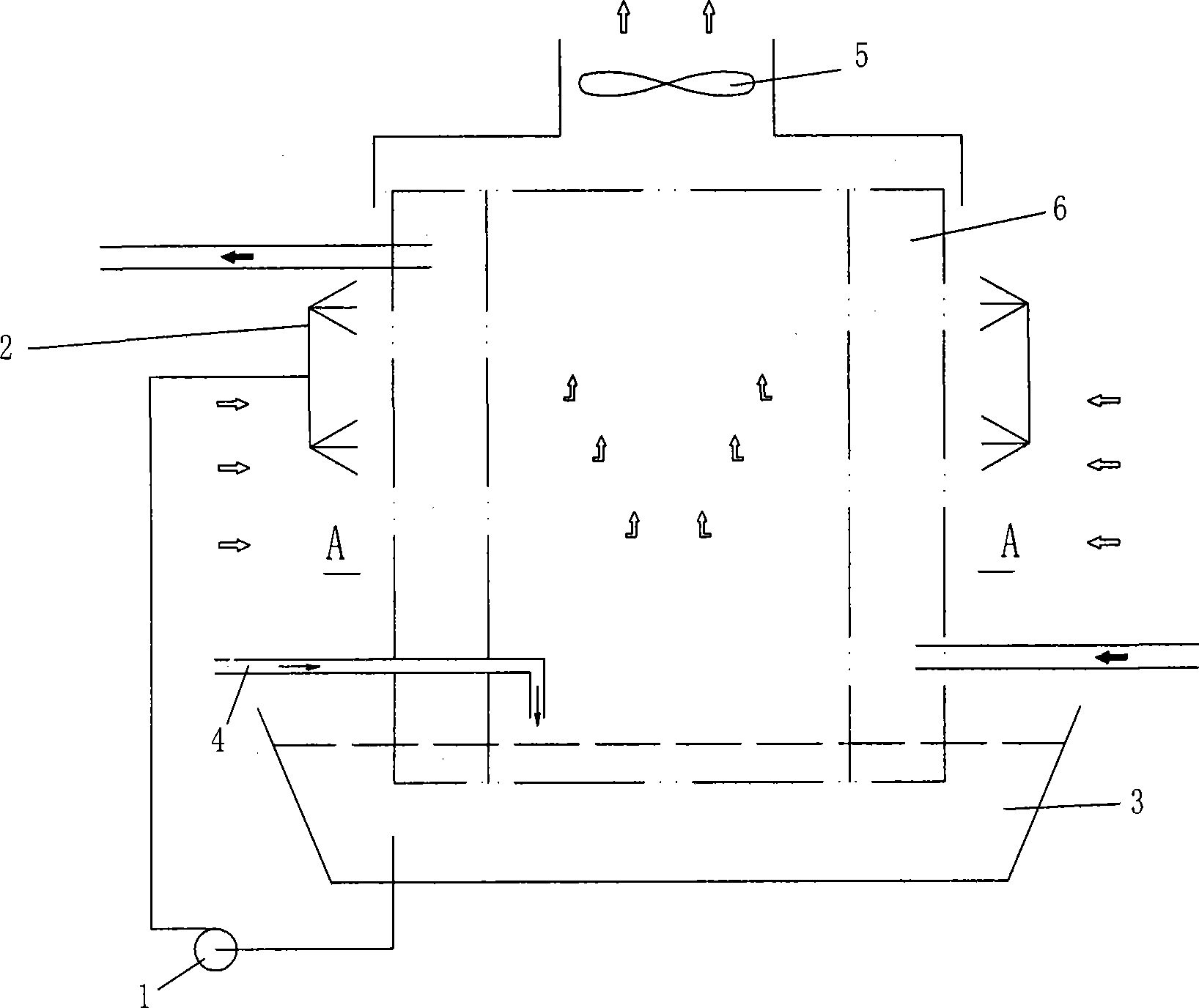

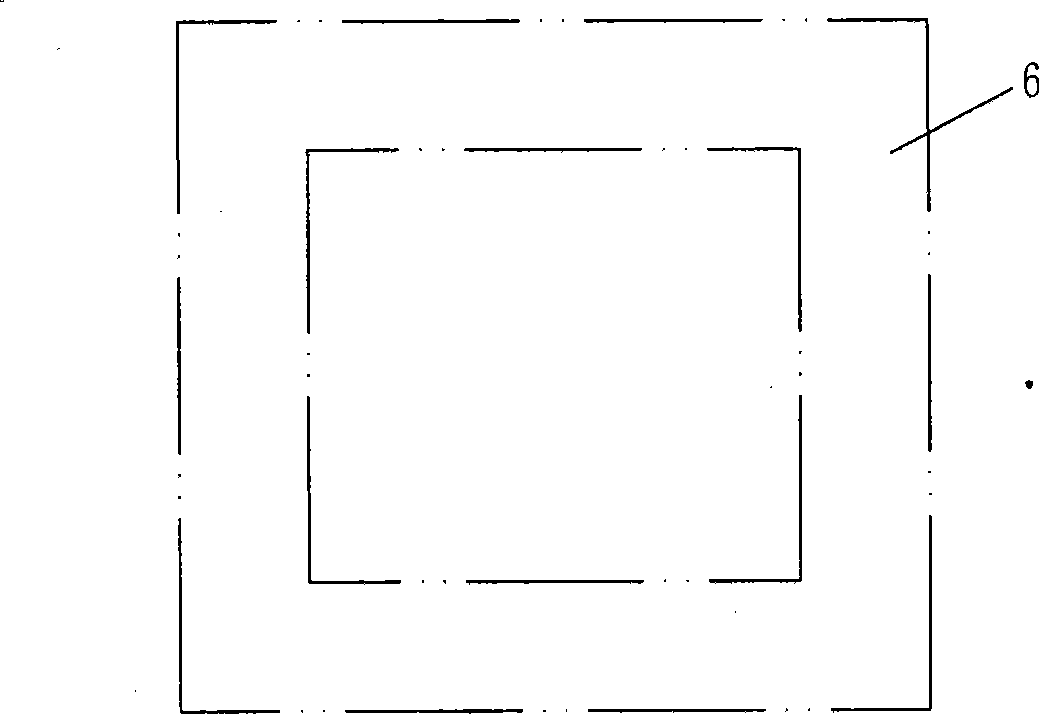

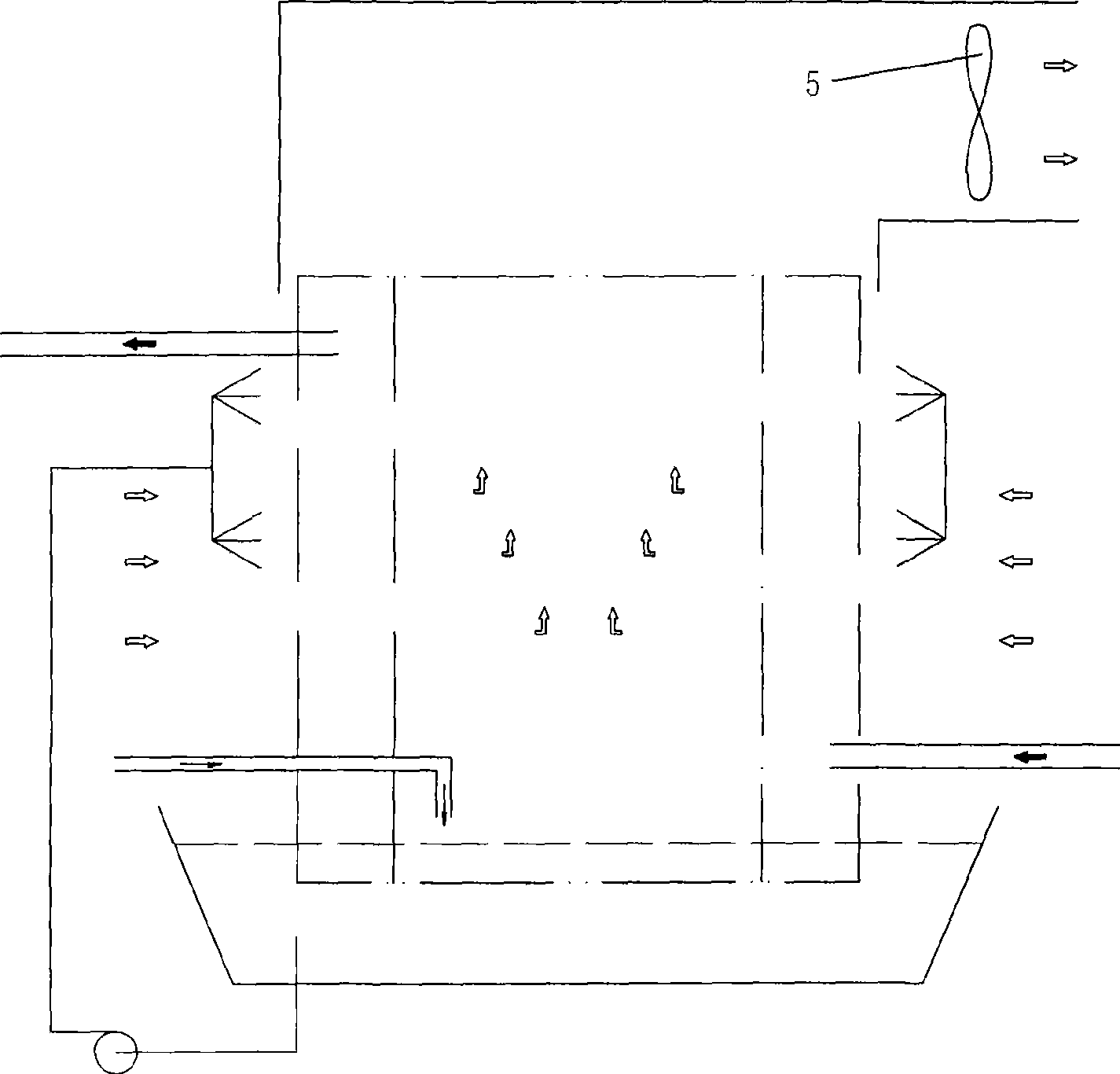

[0017] see figure 1 , the high-efficiency evaporative cooler of the present invention includes a water spray device made up of a water pump 1, a water spray nozzle 2, and a water reservoir 3, and a supplementary water pipe 4 for replenishing cooling water to the reservoir, for driving air flow Induced fan 5. The finned tubes surround a hollow vertical cylinder 6 . Since the specific arrangement structure of finned tubes can be flexibly designed, so figure 1 The specific arrangement structure of the finned tubes is not drawn, but the overall longitudinal cross-sectional shape of the cylinder 6 surrounded by the finned tubes is abstractly drawn with double-dotted lines, figure 2 Only the overall transverse cross-sectional shape of the cylinder body 6 is abstractly drawn with double-dot-dash lines, and the shape of the cylinder body 6 is also abstractly draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com