Vibration preventing automobile instrument motor

A technology for automotive instruments and motors, applied in the field of vibration reduction and vibration isolation, to achieve the effects of reducing structural costs, stable operation, and small magnetic circuit reluctance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

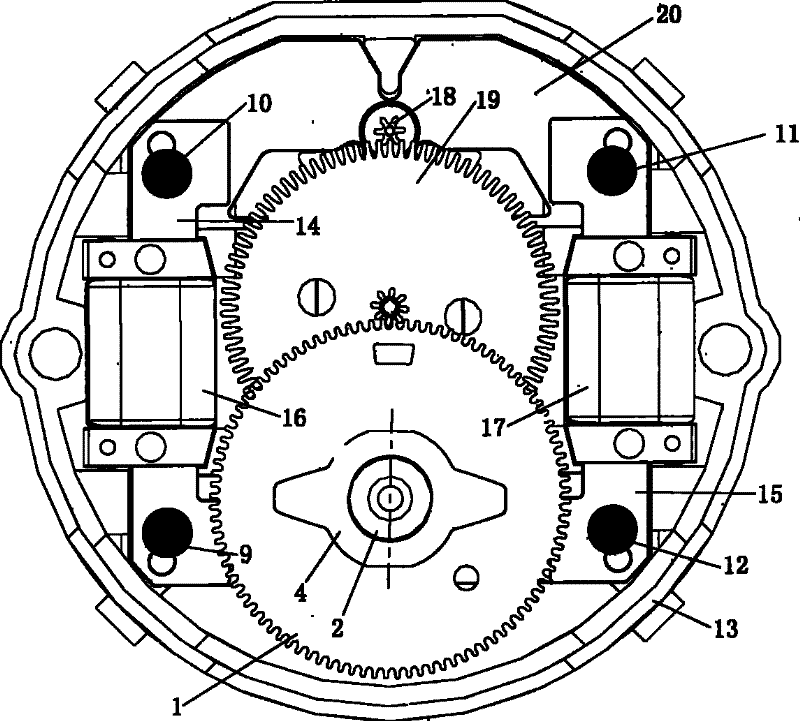

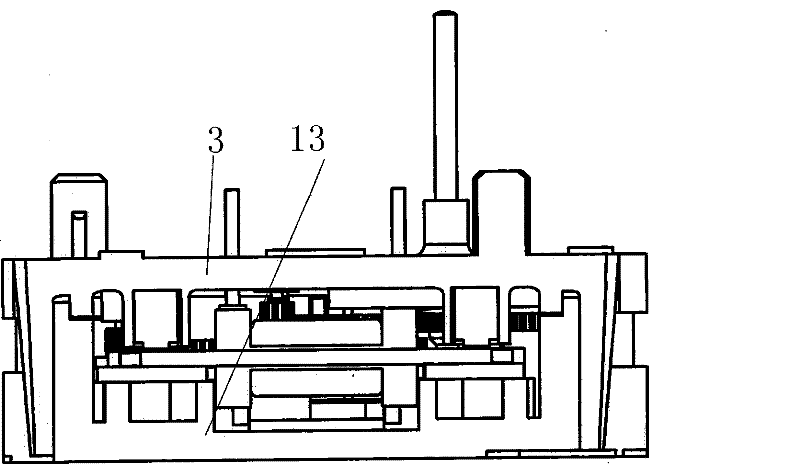

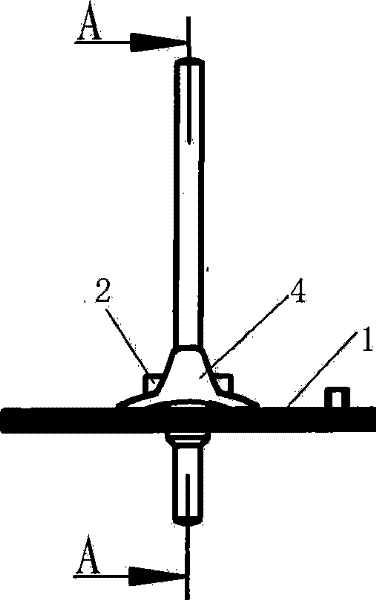

[0021] combine figure 1 and figure 2 , the anti-vibration automotive instrument motor of the present invention includes motor left and right drive coils 16, 17, left and right drive coil iron cores 14, 15, stator sheet 20, motor drive gear 18, intermediate gear 19, output shaft gear 1, upper cover 3 and lower Cover 13. A boss 2 integrated with the gear 1 is arranged on the upper surface of the output shaft gear 1, the boss 2 is a circular boss, and the diameter of the boss 2 is 3-5 mm. A stainless steel spring piece 4 is set between the inner surface of the gear 1 and the upper cover 3, the middle hole of the stainless steel spring piece 4 is matched with the boss 2, and the convex surface of the stainless steel spring piece 4 is in contact with the surface of the gear 1, as image 3 and Figure 4 . The inner diameter R1 of the stainless steel spring piece 4 is equal to the diameter of the boss 2 plus 0.3mm, the forming radius R of the stainless steel spring piece 4 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com