Servobrake

A technology of amplifier and braking force, which is applied in the direction of brakes, braking transmissions, transportation and packaging, etc., and can solve problems such as annoying noise, response of brake force amplifier and adverse effects on release time dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

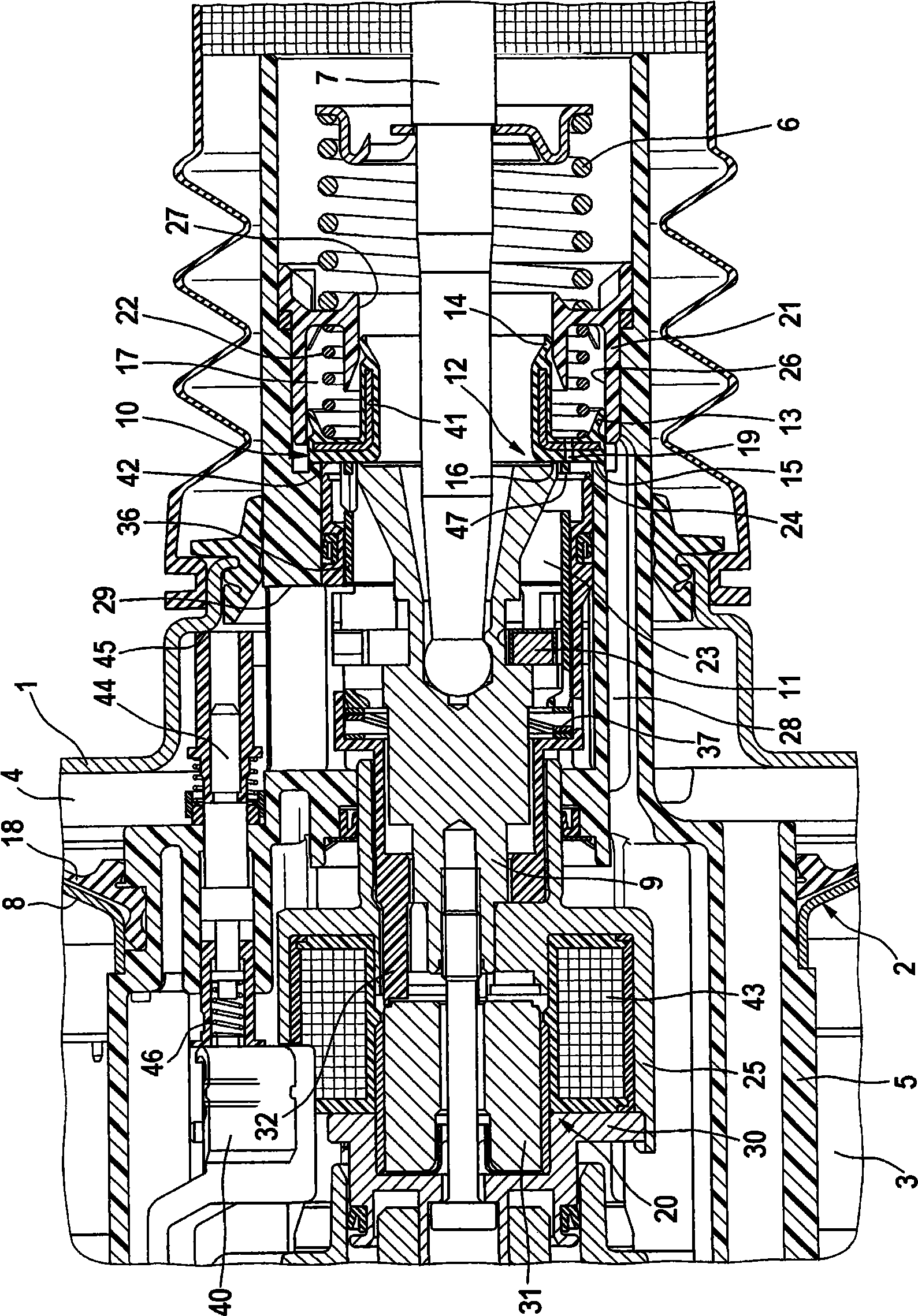

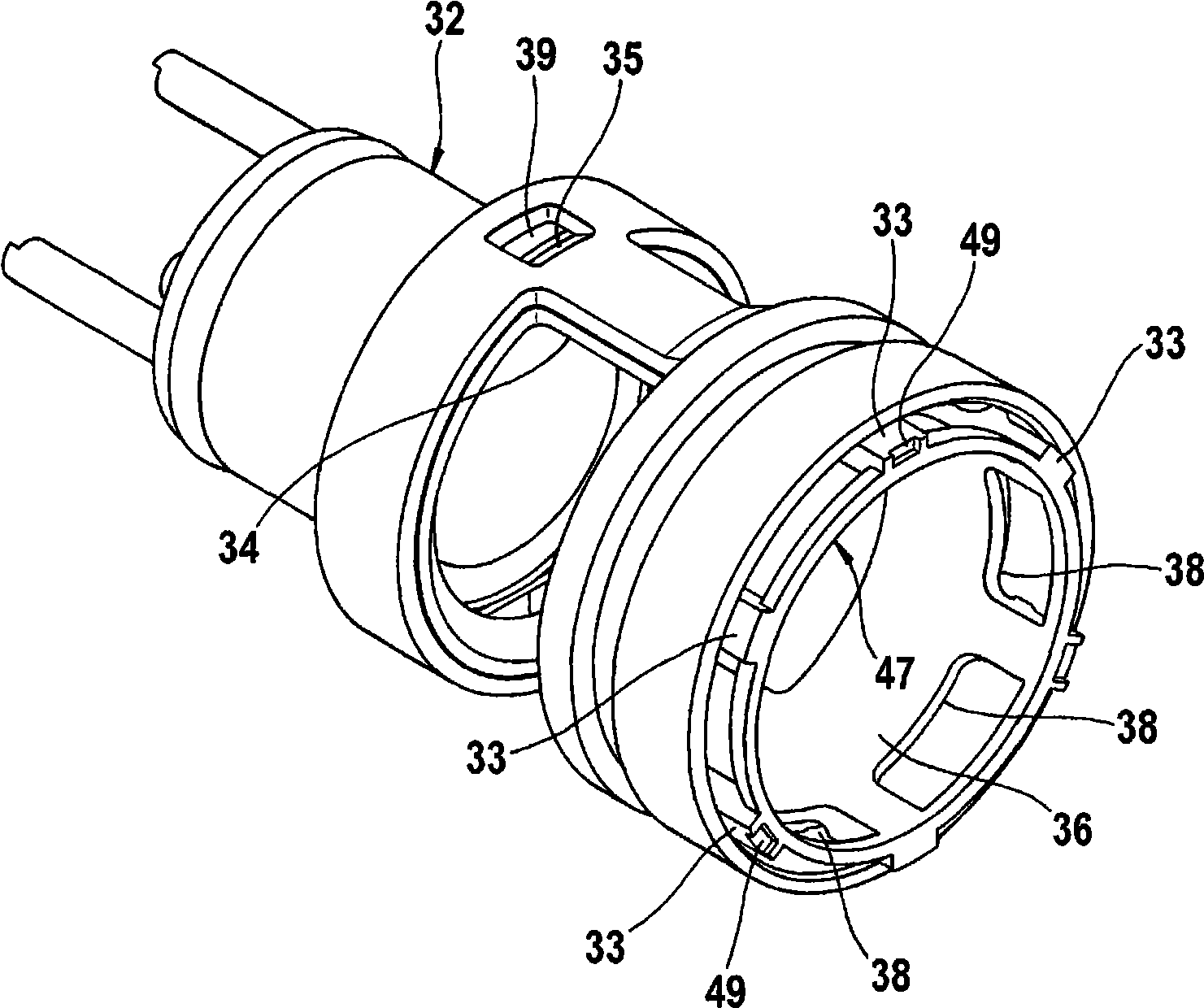

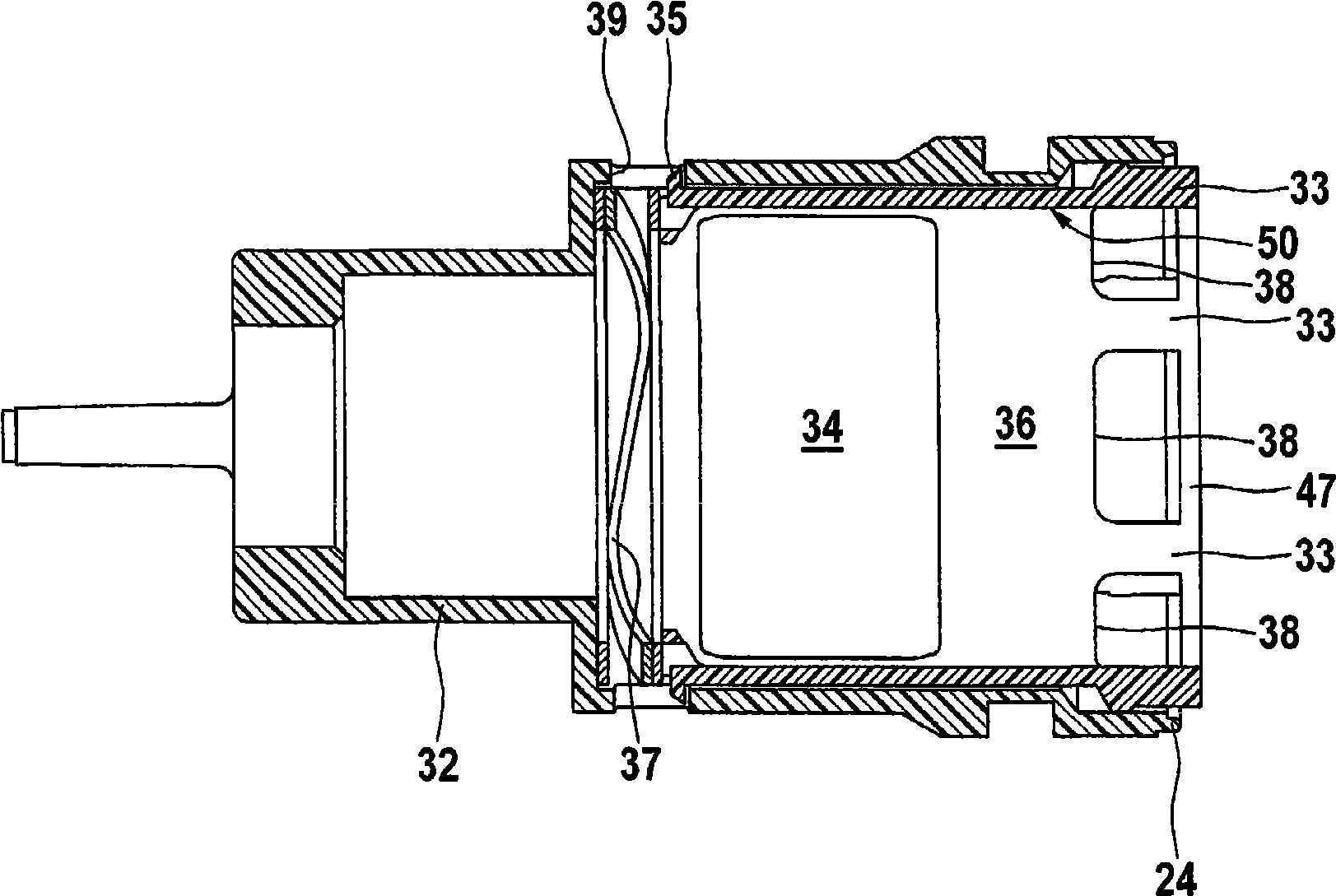

[0016] The only schematically indicated booster housing 1 of the brake booster according to the invention is divided by an axially movable wall 2 into a low-pressure chamber 3 and a working chamber 4 . The axially movable wall 2 comprises a disc-shaped diaphragm 8 made of deep-drawn sheet material and a flexible diaphragm 18 adhering to it. A diaphragm roll acts as a seal between the amplifier housings 1 .

[0017] A control valve 12 operable by means of a joystick 7 is mounted in a controller housing 5 which moves sealingly within the amplifier housing 1 and supports the movable wall 2, said control valve comprising a A first sealing seat 15 formed on the device housing 5, a second sealing seat 16 formed on the valve piston 9 connected to the operating rod 7, and a cooperating with the two sealing seats 15, 16 and on the guide 21 The valve body 10 that moves inside, the guide member is sealed and immovably installed in the controller housing 5, said valve body has an L-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com