Push-and-pull type die turning-over device

A technology of push-pull and mold machine, which is applied in metal processing and other directions, can solve the problems of easily smashing the workshop floor, impact tension of cranes, safety accidents, etc., and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

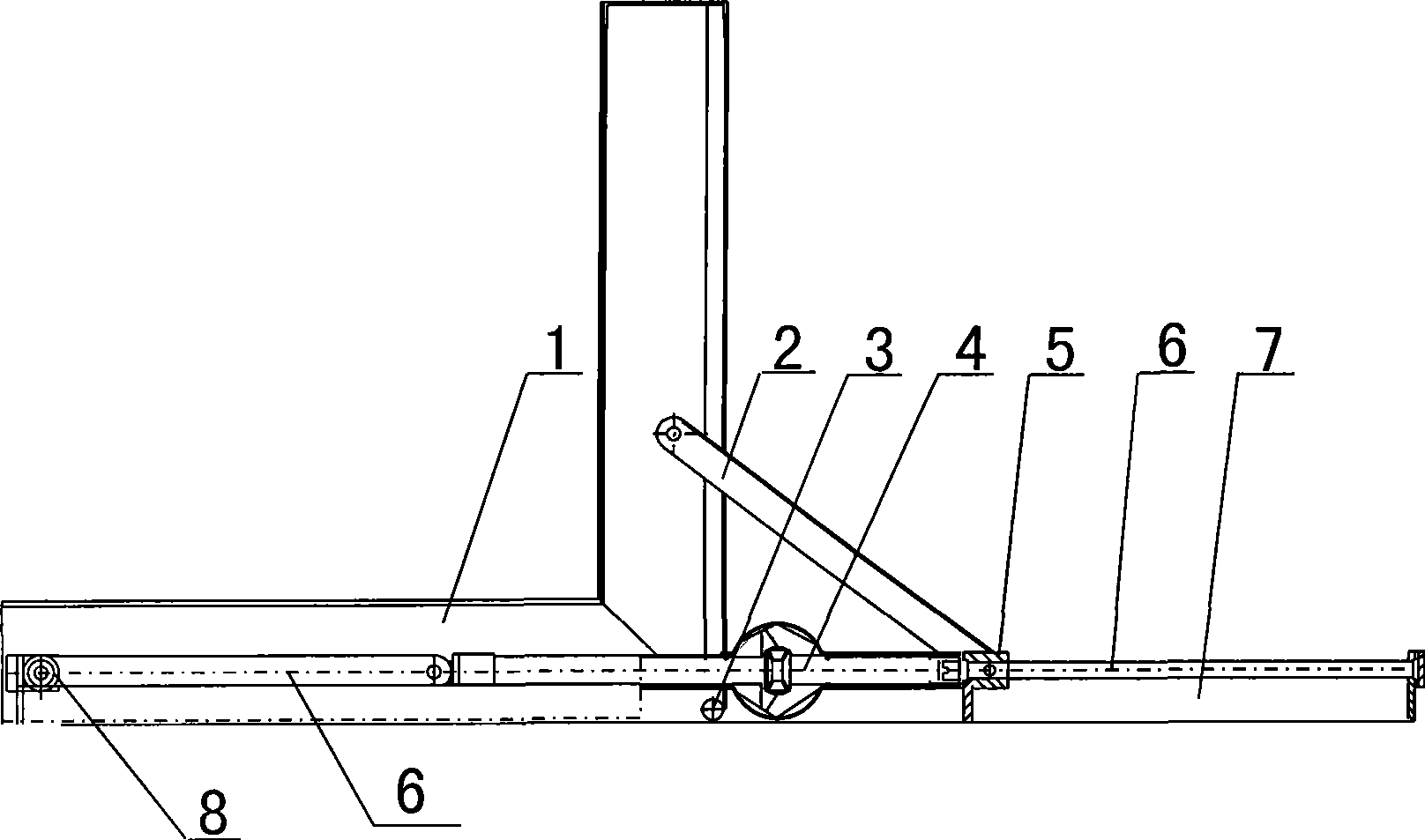

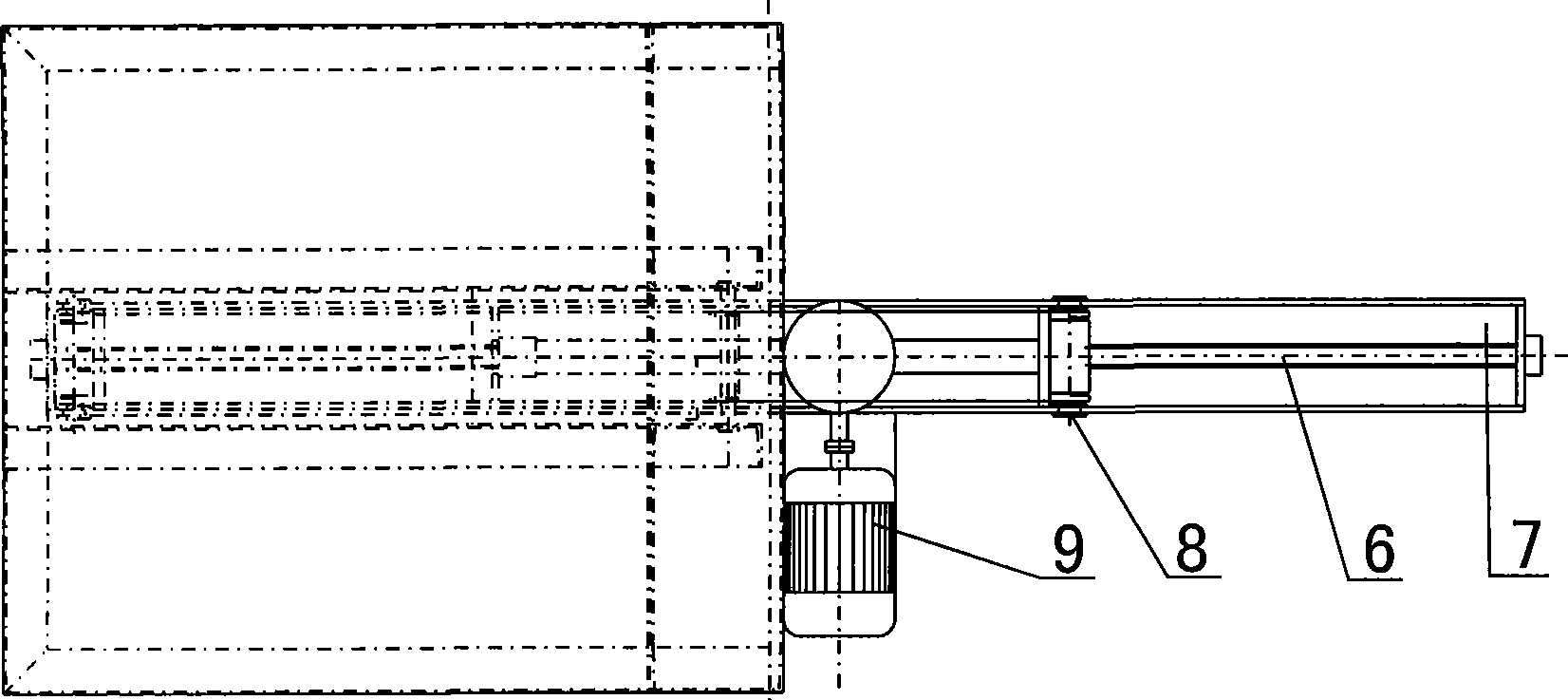

[0014] Embodiment 1: described push-pull type overturning machine comprises the overturning table body 1, chassis 7 that is used for placing and overturning mould, motor and differential gear are set on underframe 7, over underframe 7 and overturn mold Push-pull rods 2 are respectively arranged between the two sides of the table body 1, one end of the push-pull rod 2 is hinged with the turning table body 1, and the other end is connected with the nut 5, the nut 5 is arranged on the lead screw 6, and the lead screw 6 is horizontally arranged on the bottom On the frame 7, the leading screw 6 is connected with the differential 4. Load bearing wheels 8 are arranged on both sides of the nut 5. The load bearing wheels 8 are used to directly bear the weight of the mold on the chassis, so that the screw only bears the axial driving force to the nut and does not bear the weight pressure of the mold. Because the push-pull point of the push-pull rod 2 is closer to the rotating shaft and ...

Embodiment 2

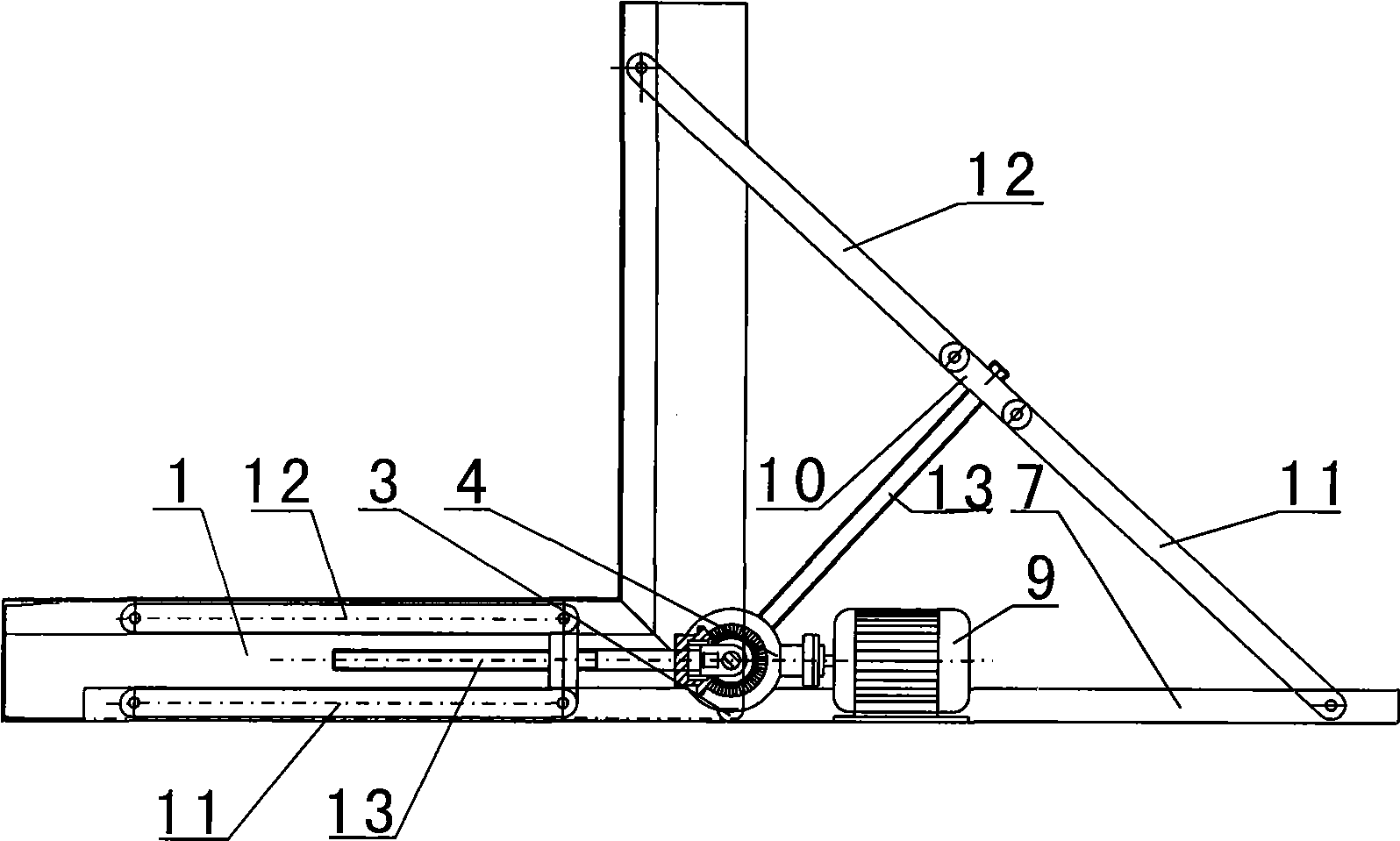

[0015] Embodiment 2: It is basically the same as the main body structure in the embodiment, the difference lies in the structure of the lead screw and the push-pull rod. The screw rod is a swing screw rod 13, which can move up and down along with the movement of the push-pull rod. The push-pull rod includes an upper pull rod 12 and a lower pull rod 11, and a hinge nut 10 is arranged between the upper and lower pull rods. One end of the leading screw 6 is connected to the hinge nut 10, the other end is connected to the differential 4, the upper end of the upper pull rod 12 is hinged to the turning table body 1, the other end is hinged to the hinge nut 10, and the upper end of the pull rod 11 is hinged to the hinge nut 10. The lower end and the chassis 7 are hinged. Because the push-pull point of the push-pull rod is far away from the rotating shaft and the push-pull force is relatively large, it is suitable for turning over heavy molds, but its structure is slightly more compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com