Silent saw blade matrix

A base and saw blade technology, which is applied in the field of sound-absorbing saw blade base, can solve the problems of long production cycle, difficulty in ensuring operation safety, and reducing the performance of saw blades, so as to achieve the effect of reducing noise and reducing the probability of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

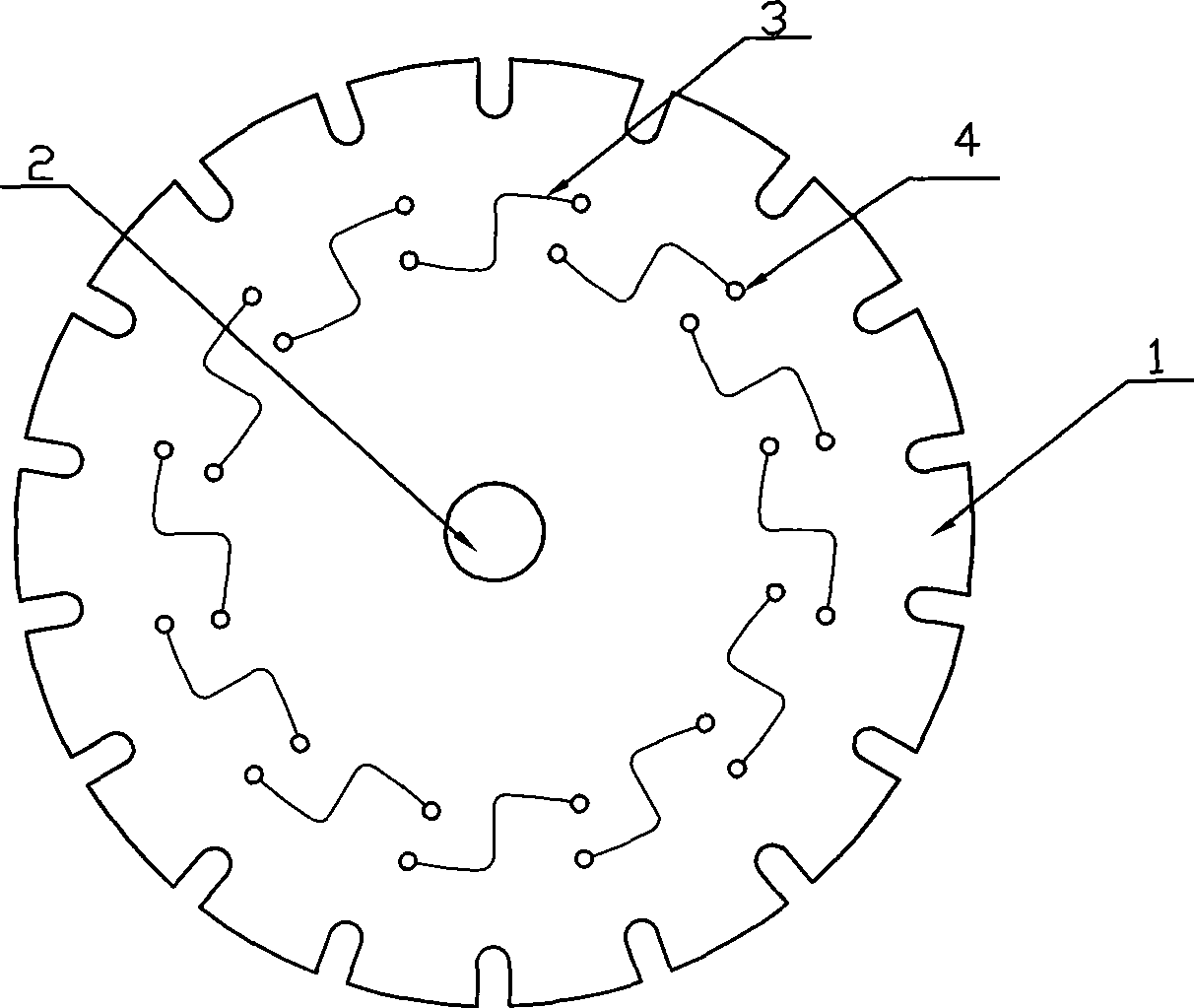

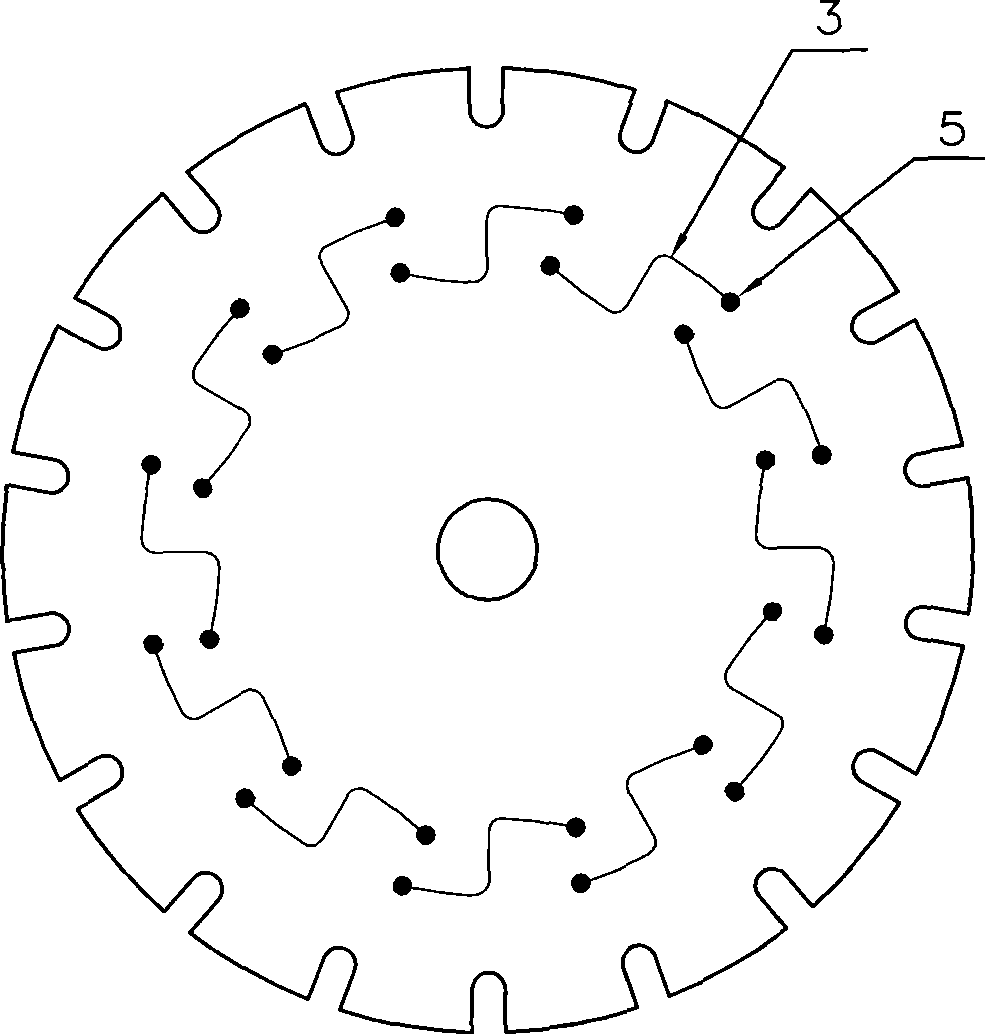

[0009] like figure 1 As shown, the present invention includes a saw blade base body 1, a central hole 2 is opened in the center of the saw blade base body 1, and noise-absorbing seams 3 are symmetrically distributed along the center hole 2 on the saw blade base body 1, and stoppers 4 are arranged at the ends of the sound-absorbing seams 3. A copper nail 5 is embedded in the crack relief hole 4 .

[0010] The environment-friendly sound-absorbing saw blade produced according to this plan, taking the Φ350mm saw blade as an example, compared with the traditional laser kerf saw blade, the noise is reduced by about 3dB(A), and compared with the "sandwich" compound saw blade, the processing difficulty is much greater reduced without cracks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com