Flat parsion shaping mechanism of plastic hollow shaping device

A technology of flat blanks and forming mechanisms, which is applied in the direction of hollow objects, flat products, household appliances, etc. It can solve the problems of prolonged processing time, large moving range, and high energy consumption of plastic hollow molding machines, so as to improve processing efficiency and reduce structure , the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

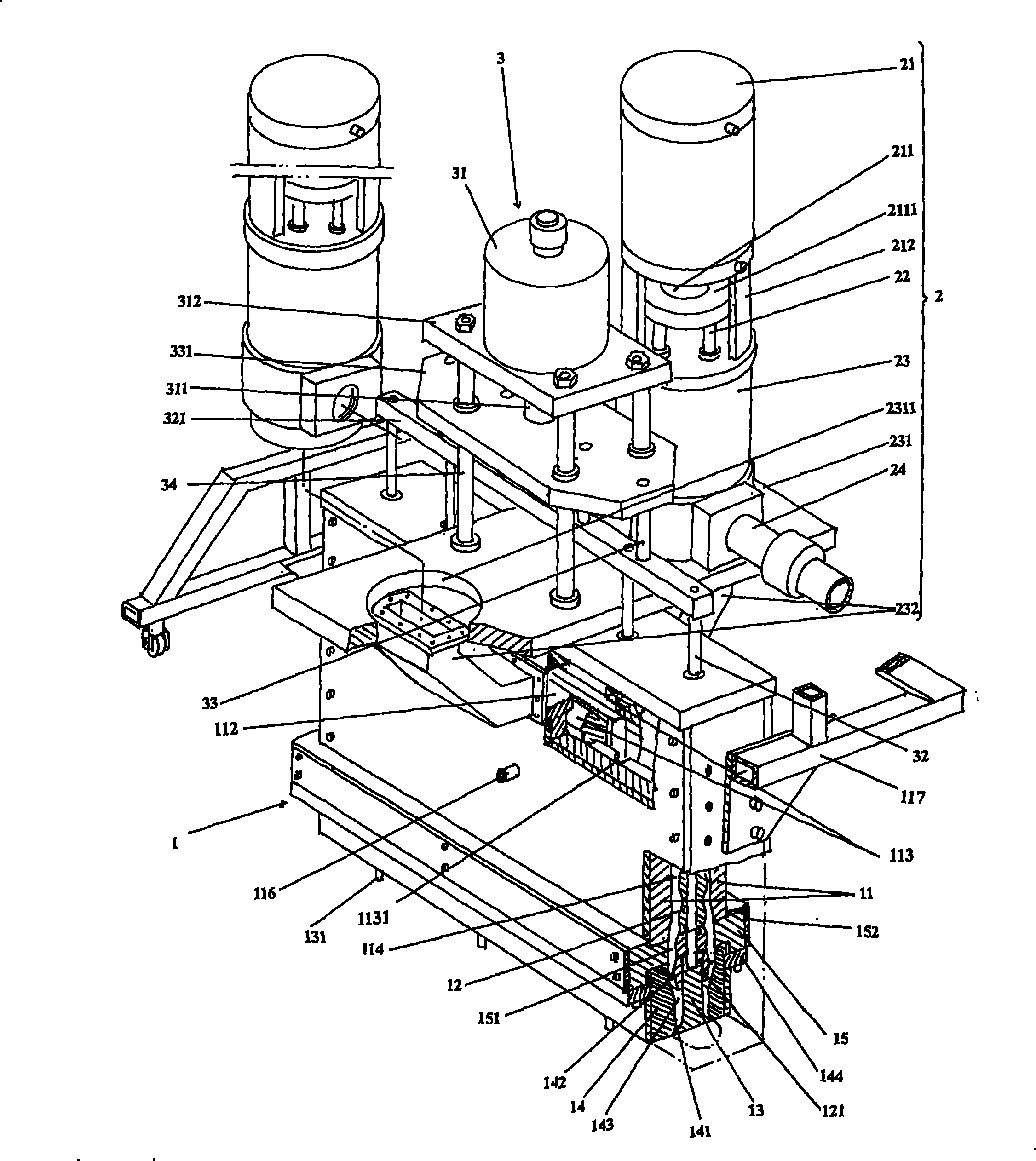

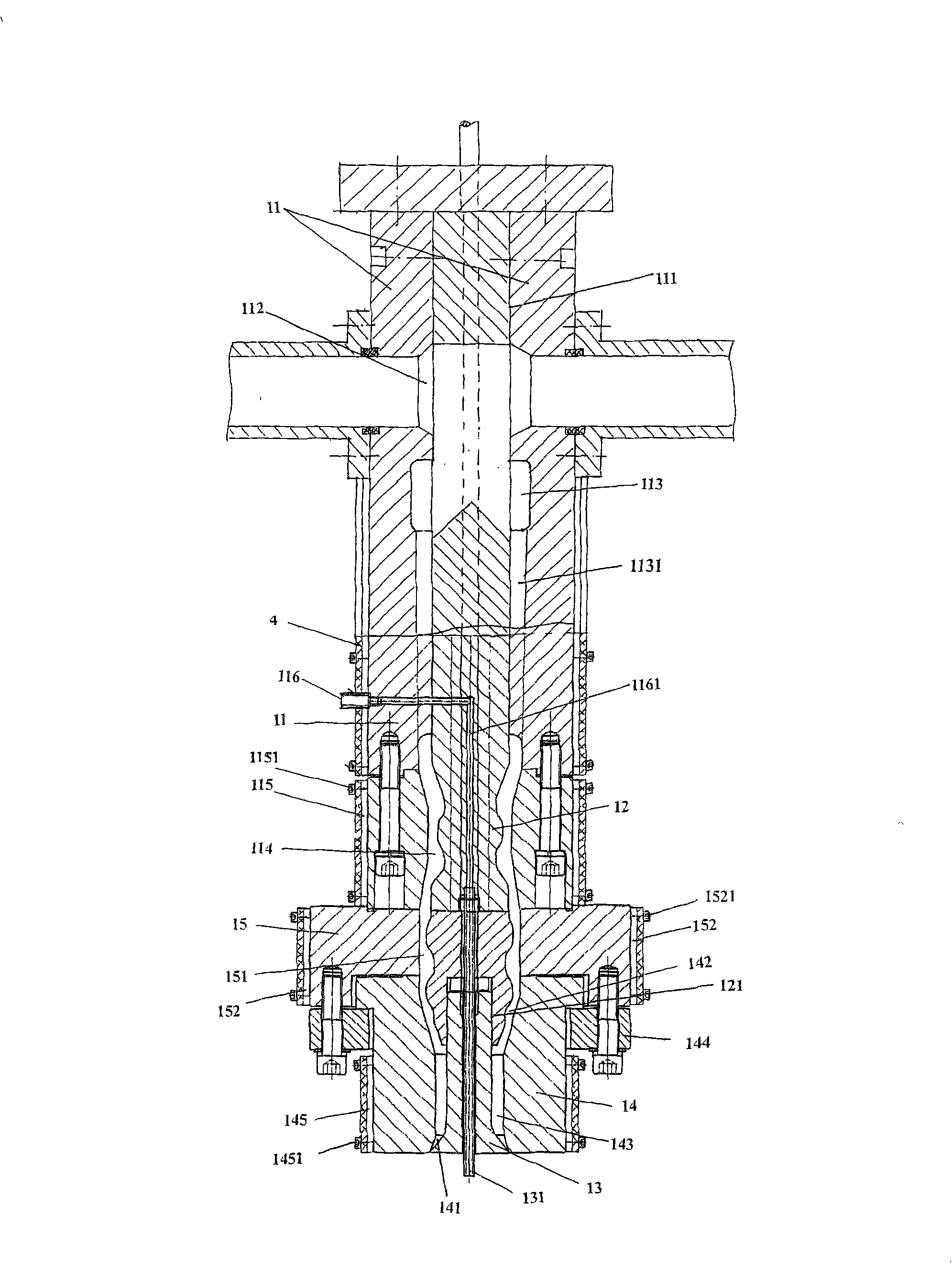

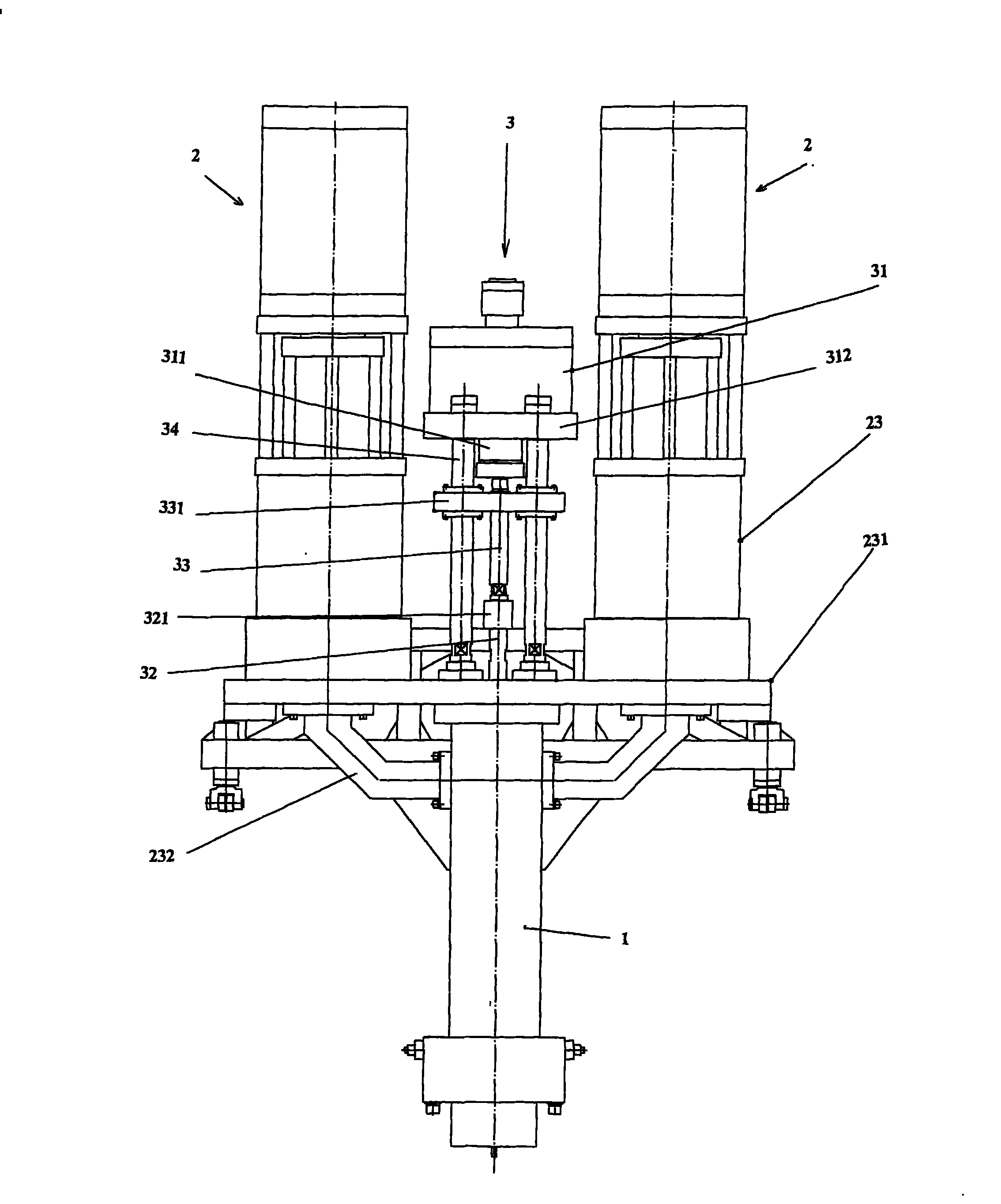

[0022] please see figure 1 and figure 2 , a molding head 1 with a rectangular shape and a flat structure is given. The length direction of the head body 11 is formed with a core body groove 111 toward the central part, and the shape of the flat die body 11 is formed by the existence of the core body groove 111. structure, preferably a flat mold core body 12 is fixed in the mold core body groove 111 with screws or in other similar ways, and the lower end of the mold core body 12 protrudes out of the mold core body groove 111 and extends through the connecting seat 15 to In the mold casing 14, a mold core groove 121 matching the mold core 13 is provided in the length direction of the lower end of the mold core body 12 located in the mold sleeve 14, and the upper part of the mold core 13 in the length direction is inserted into the mold core In the groove 121, the lower part of the length direction is accommodated in the die cover 14 and matches with the discharge port 141 (p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com