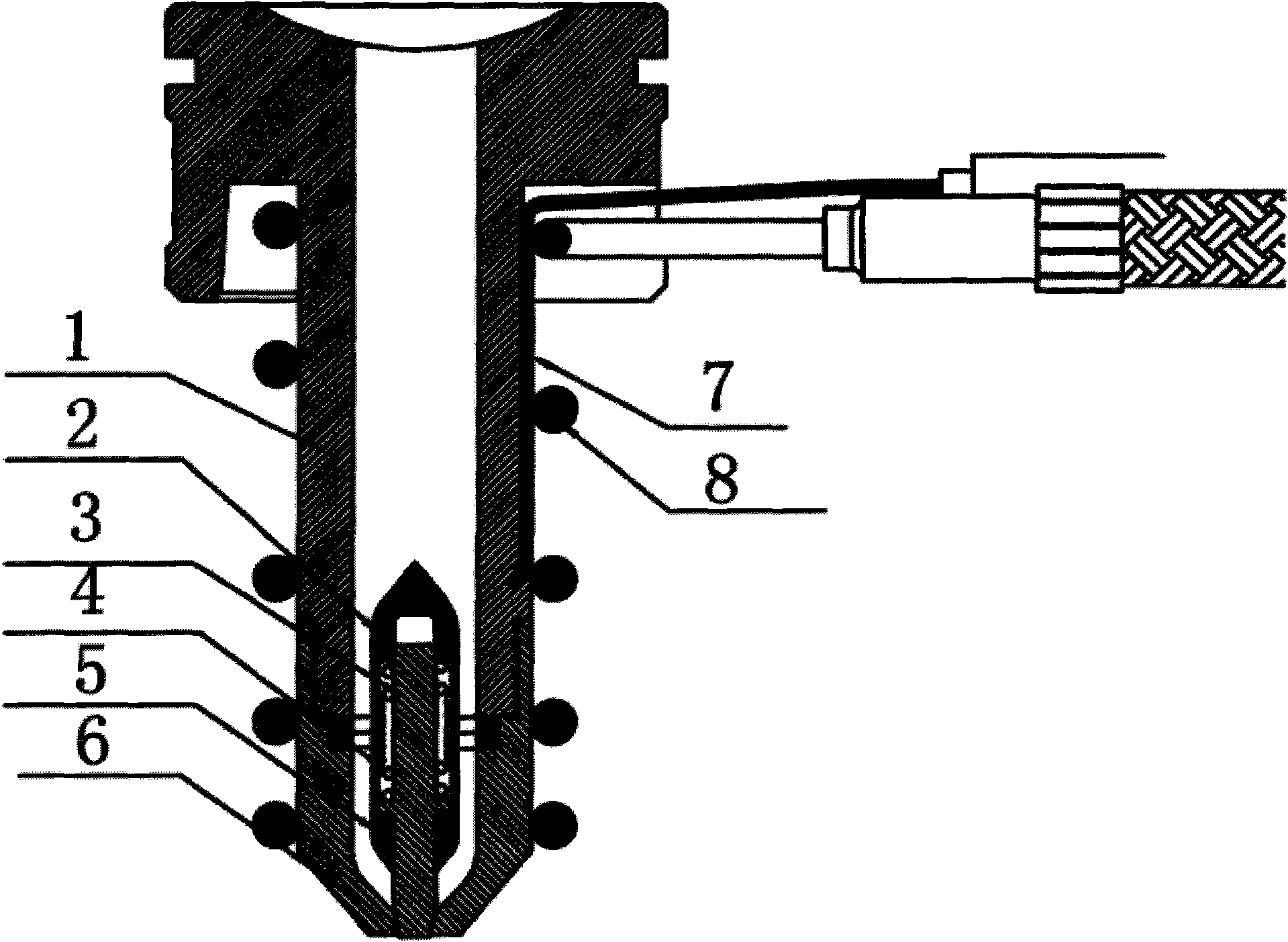

Hot runner system and gas spring type nozzle thereof

A hot nozzle and hot runner technology, applied in the field of hot runner system, can solve the problem of difficult analysis results, and achieve the effects of saving raw materials, improving product quality, and convenient setting of molding conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

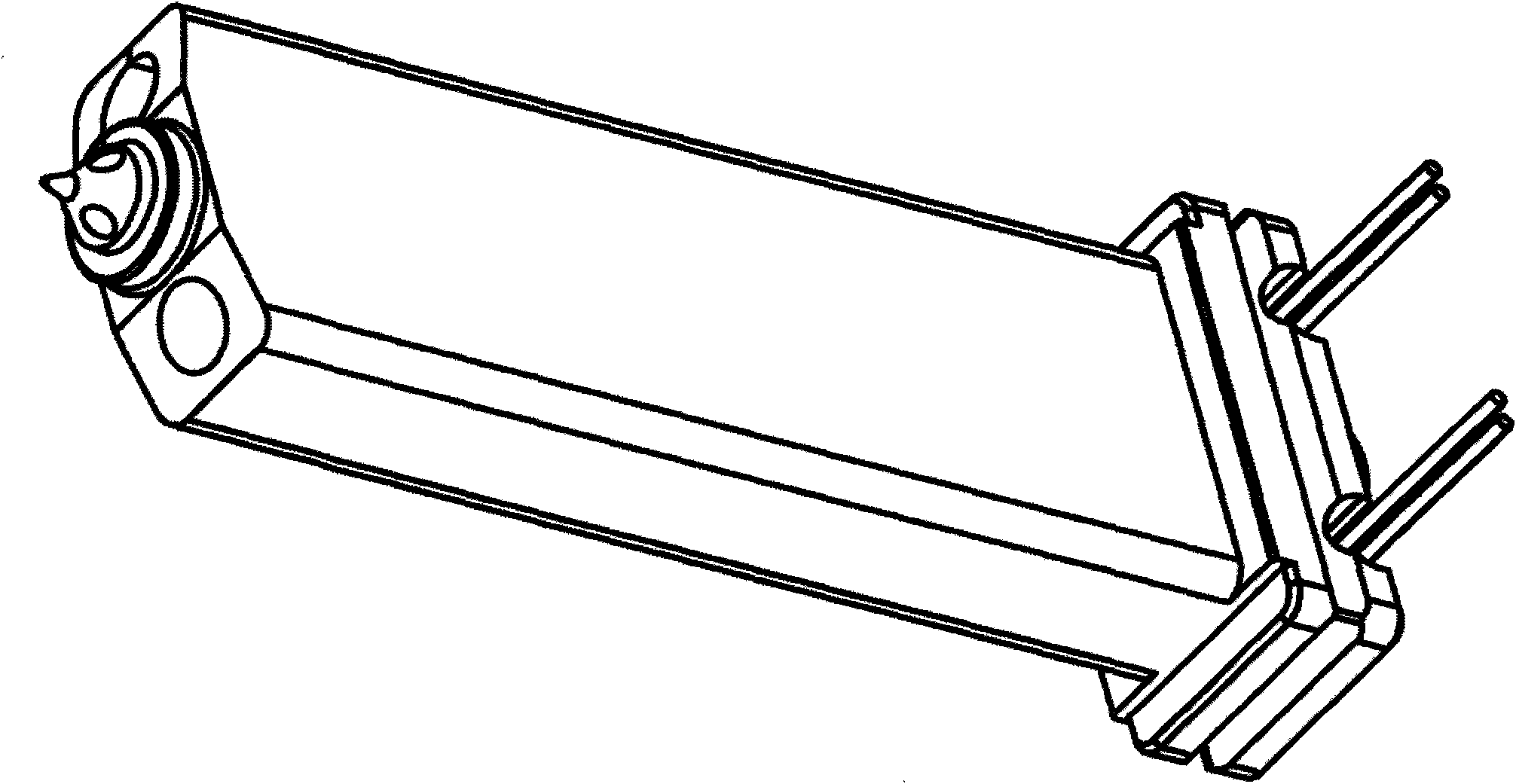

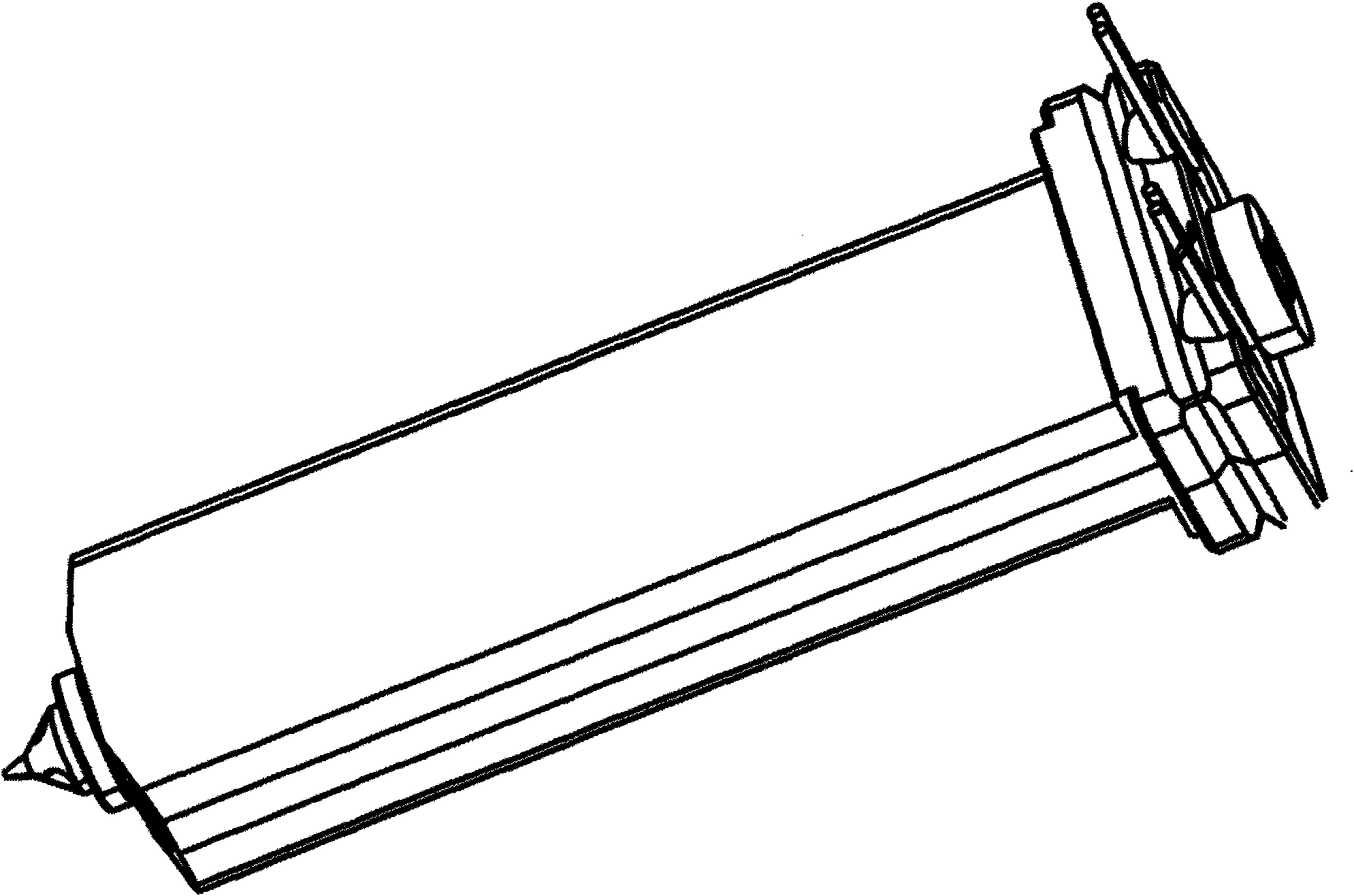

[0088] In order to have a further understanding and understanding of the structural features of the present invention and the effects achieved, the preferred embodiments and accompanying drawings are used in conjunction with detailed descriptions, and the descriptions are as follows:

[0089] Due to some defects in the current hot runner system, such as complex mold structure, easy damage of heater components, high manufacturing cost, need for more precise temperature control device, molding resin must be clean and free of debris, resin replacement and color change are difficult, maintenance More complex, etc., but these shortcomings are gradually being overcome. At present, the main development trends of hot runner molds at home and abroad can be summarized into the following aspects.

[0090] Miniaturization of components to achieve multi-cavity in one mold for small products and multi-gate filling for large products. By reducing the nozzle space, more cavities can be configu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com