Heavy duty car CAN control system flexible collocation method based on bussing technique

A heavy-duty vehicle and control system technology, applied to vehicle components, circuits or fluid pipelines, transportation and packaging, etc., can solve problems such as heavy workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

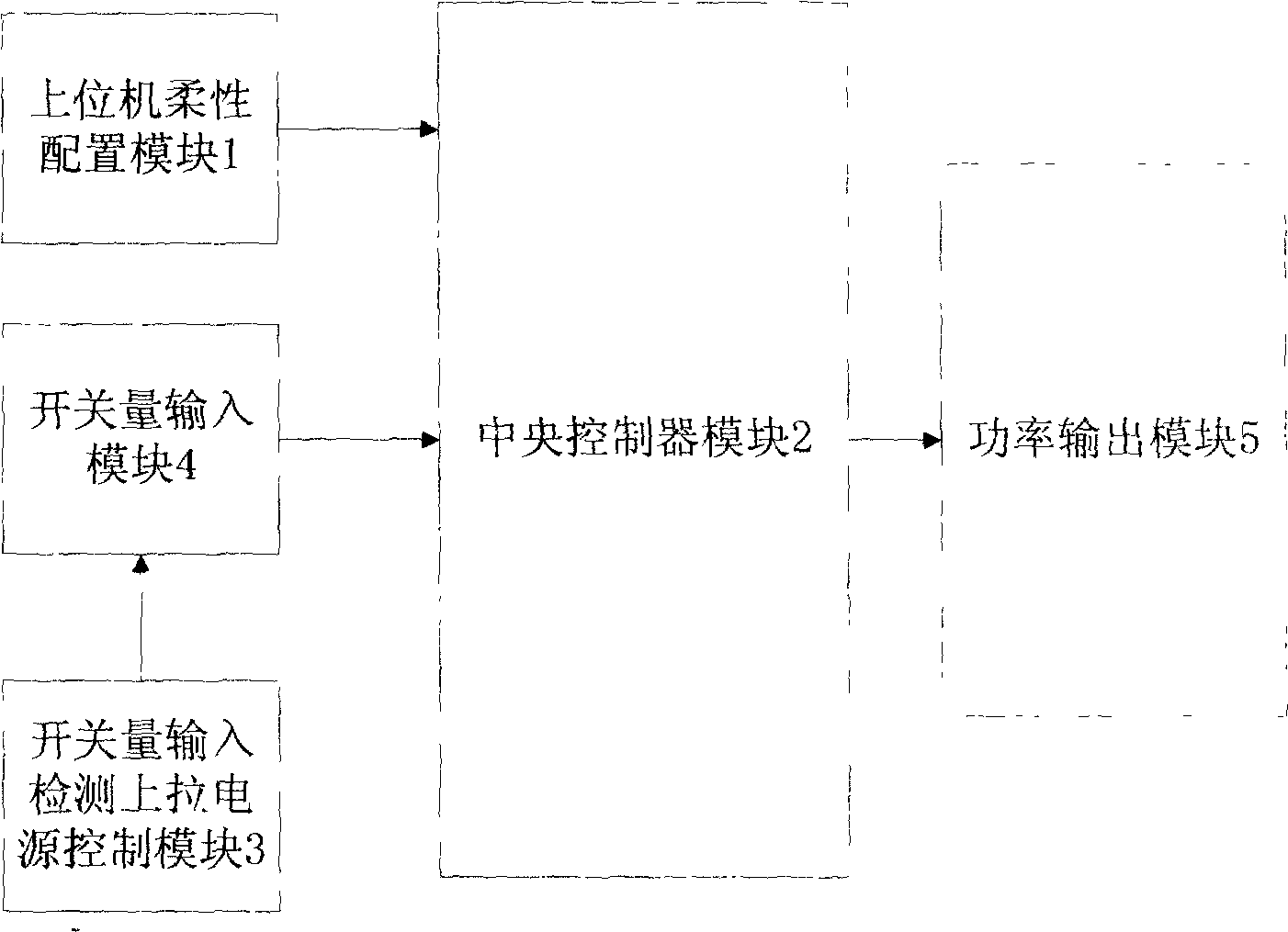

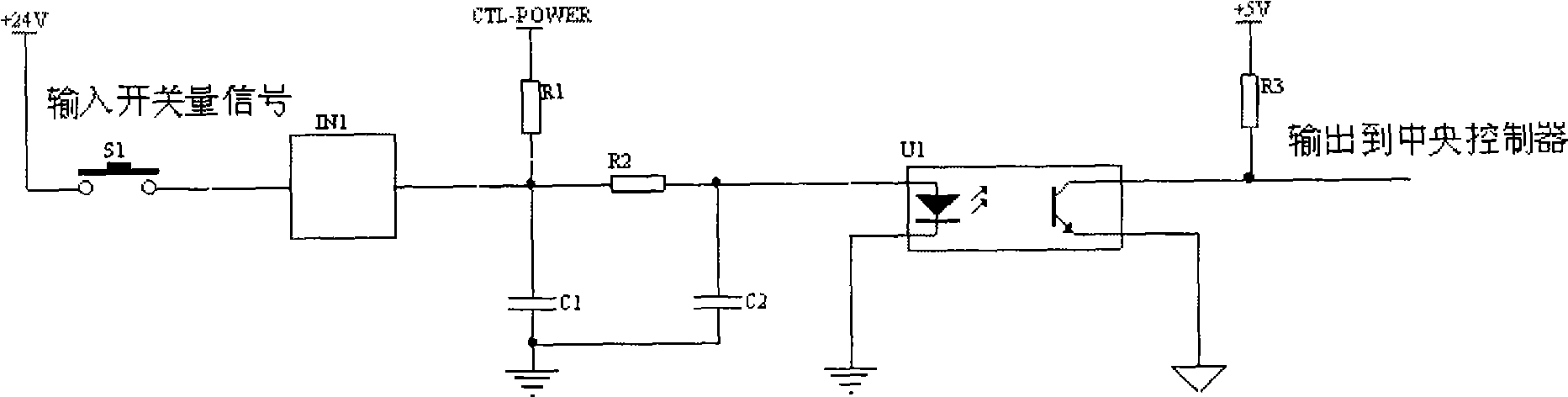

Method used

Image

Examples

specific Embodiment

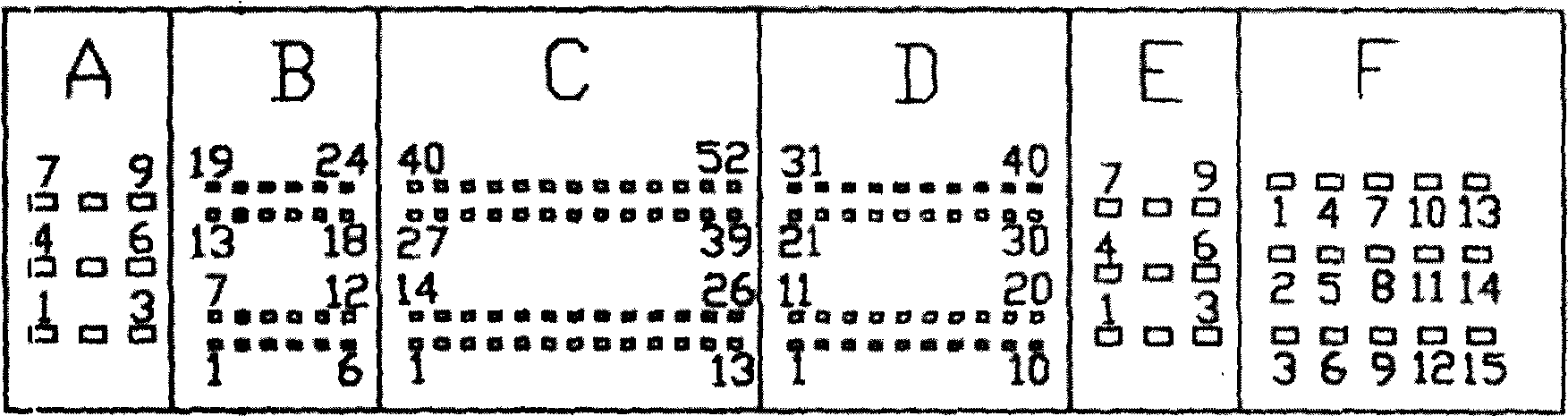

[0029] The reversing light circuit and the right turn signal circuit are selected to complete the circuit function design by using the flexible configuration method. Assuming that the reversing light switch is a high effective input switch value, the reversing light output needs to be driven by a low-side power output, and the output drive mode is normal high; the right steering switch is a low effective input switch value, and the right steering output needs a high-side power output drive , the output drive mode is blinking. Select terminal No. 2 on port B and terminal No. 4 on port C of the switch input module 4 as the input ports of the two switch signals, define their port numbers as 0x02 and 0x04 respectively, and select the high-side power output port Terminals 8 and 9 on A are driven as high-side outputs. Select terminals 11 and 13 on the low-side power output port F as low-side output drivers, and define their port numbers as 0x08, 0x09, 0x11, and 0x13, respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com