Method for producing nano-scale aluminum oxide particle with porous alumina film

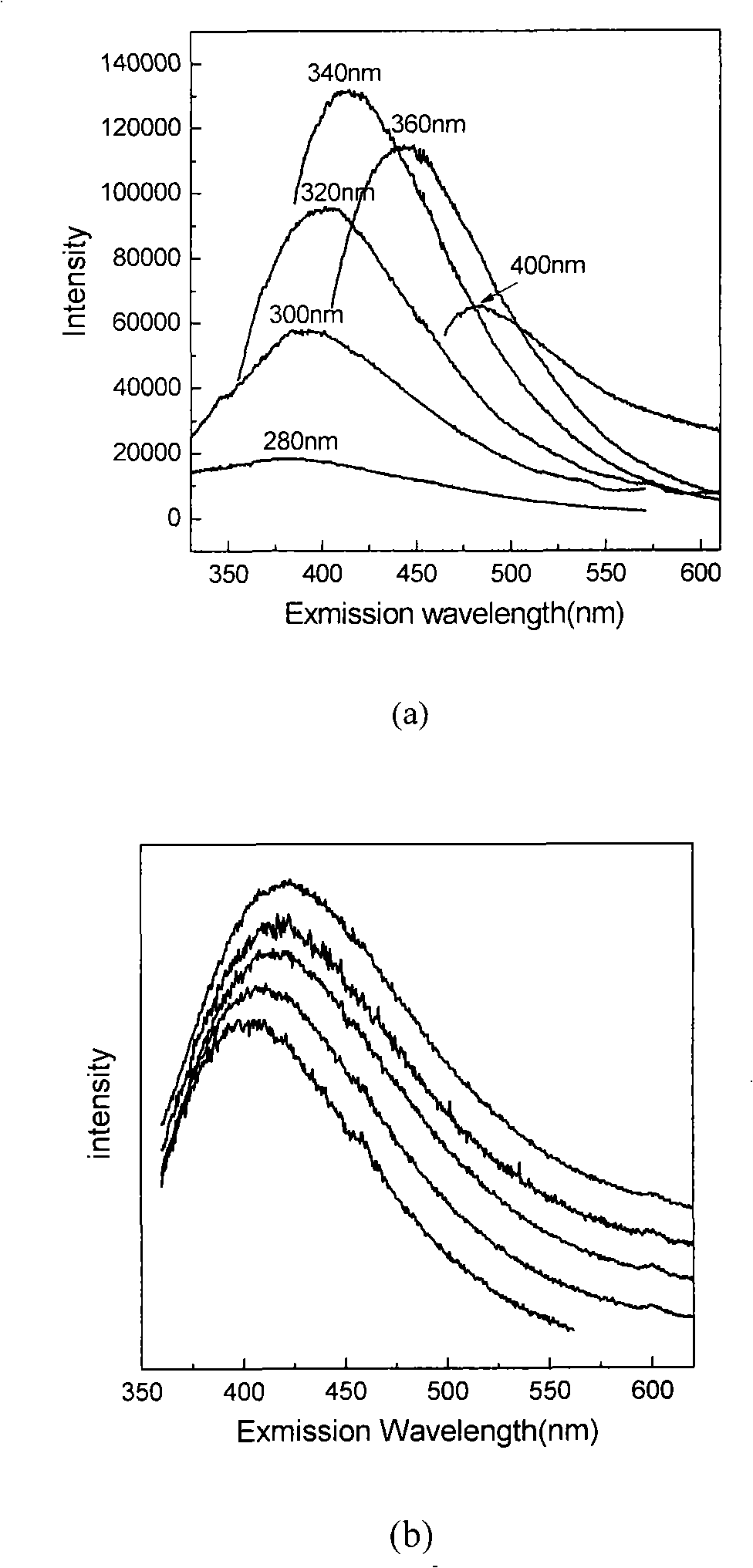

A technology of porous alumina and alumina particles, applied in alumina/aluminum hydroxide, chemical instruments and methods, luminescent materials, etc., can solve the problems of complex preparation process of alumina particles, unsatisfactory products, high cost, and achieve blue light The effect of emission, small size and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is illustrated below with specific examples.

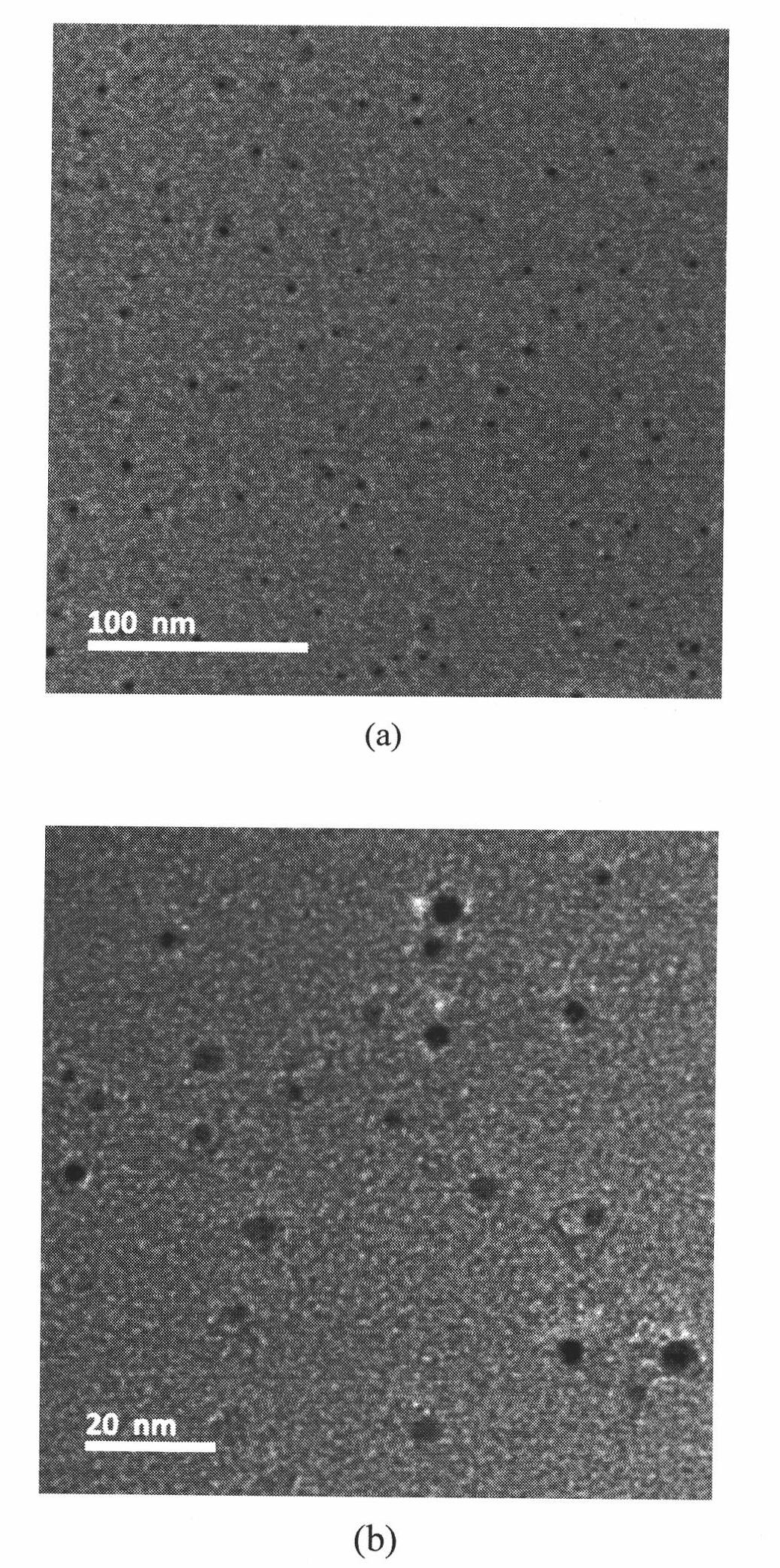

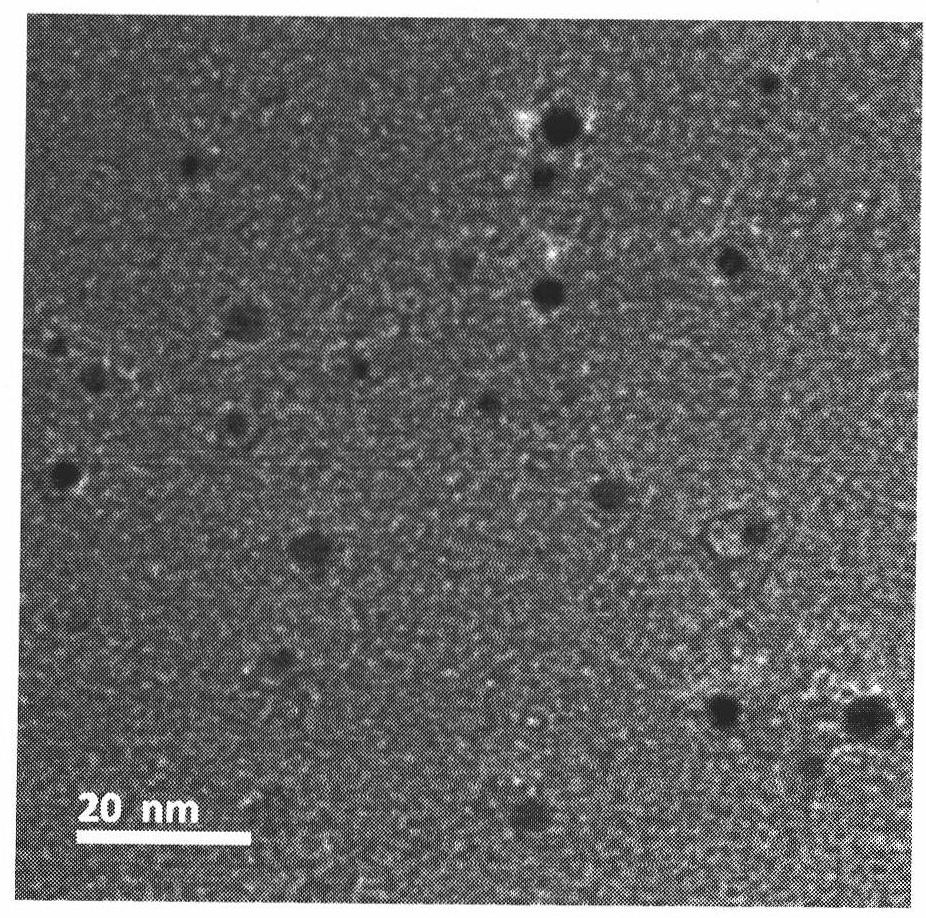

[0012] Use a 99.99% high-purity aluminum sheet with a thickness of 0.1mm, and electrochemically corrode it in an oxalic acid solution for 12 to 14 hours at a voltage of 40V to prepare a porous alumina film; place the porous alumina film in CuCl 2 In the saturated solution of porous anodized aluminum film, remove the remaining metal aluminum on the back of the porous anodized aluminum film, and then wash it repeatedly with deionized water, and after ultrasonic vibration treatment in a deionized water bath, remove the impurities on the surface of the film and in the pores, and dry it in the air , put the dried alumina film into a mortar and grind it into alumina powder; finally, place the collected alumina powder in deionized water and undergo ultrasonic vibration treatment for 1-2 hours to further crush the alumina powder , after standing and stratifying, the supernatant was taken to obtain a colloidal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com