Method for preparing monosaccharide by raw materials containing cellulose

A technology for cellulose and raw materials, applied in the field of monosaccharide preparation, can solve the problems of low monosaccharide yield and low enzymatic hydrolysis efficiency, and achieve the effects of improved enzymatic hydrolysis efficiency, uniform reaction and stable reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] This example is used to illustrate the method of the present invention for preparing monosaccharides from cellulose-containing raw materials.

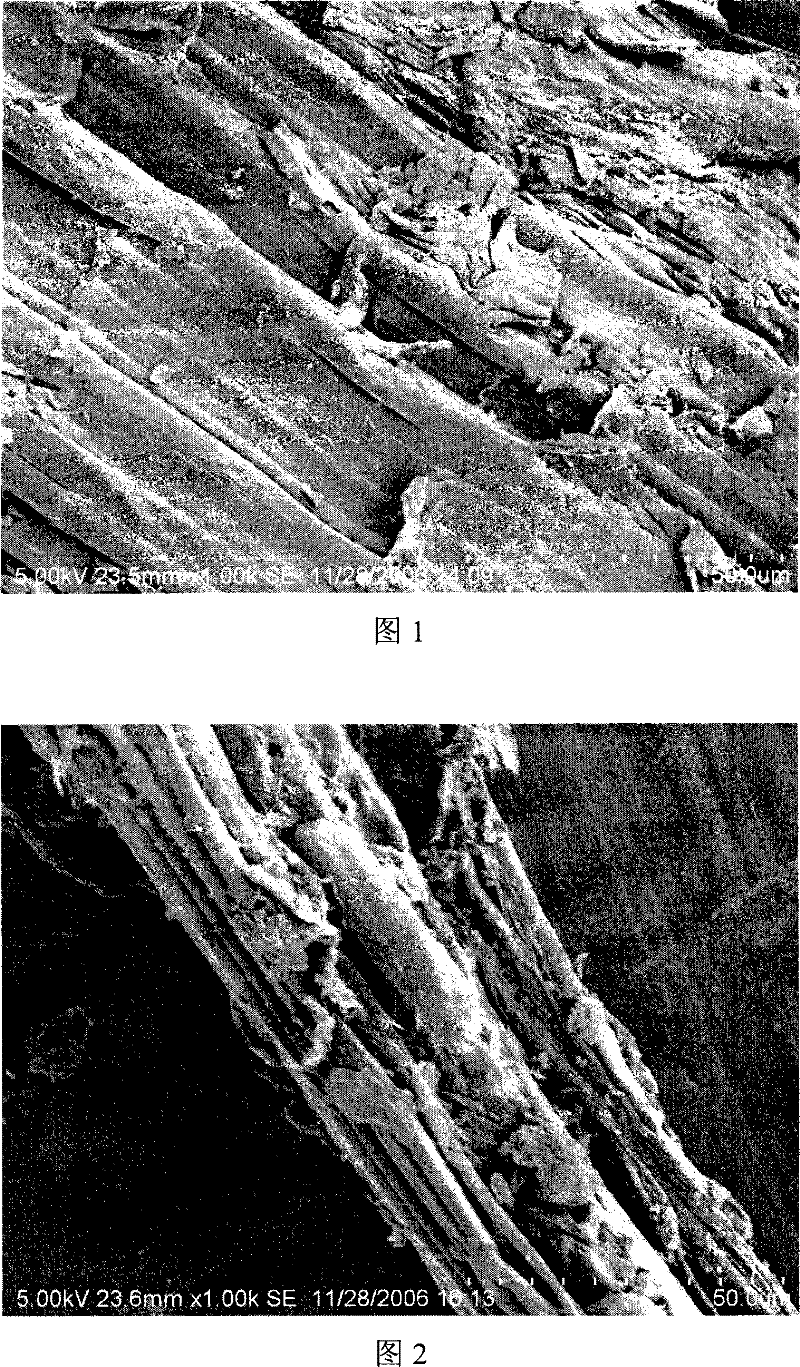

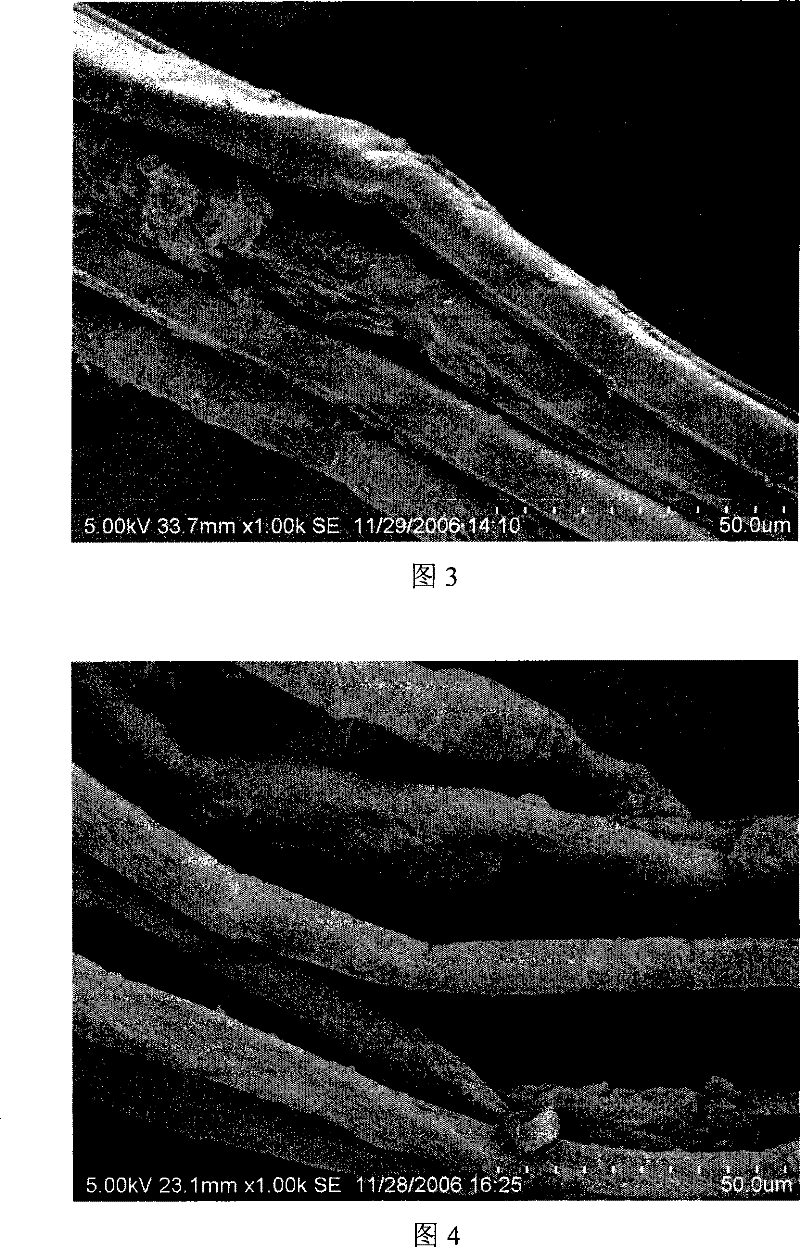

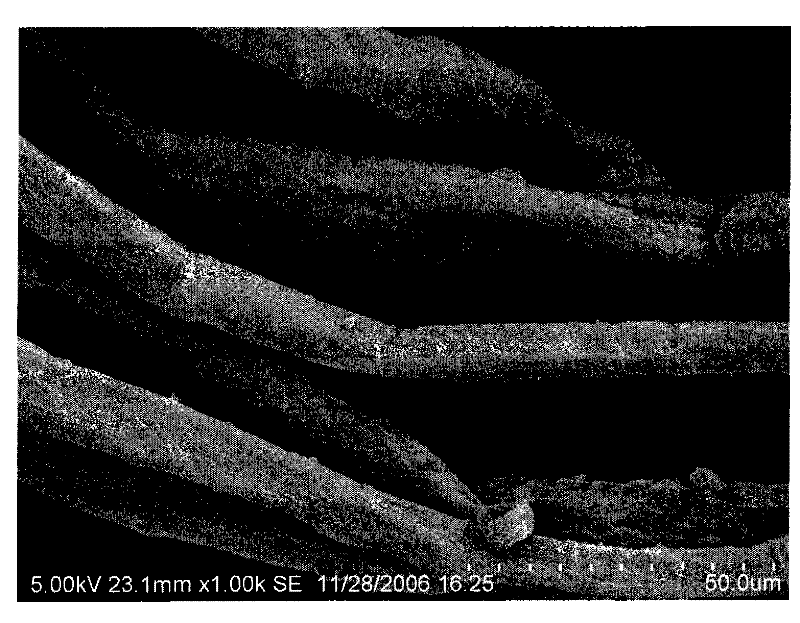

[0059] (1) Steam explosion

[0060] test as figure 1 For the corn stalk raw material shown, the water content of the corn stalk measured according to the above-mentioned method is 20% by weight, the raw material is cut into 1.5 cm × 0.2 cm × 0.5 cm segments, and the vertical impregnator (Shandong Wenrui Machinery Co., Ltd. ) mixed with water whose weight is one-third of the weight of the corn stalk raw material, corn stalks with a water content of 40% by weight can be obtained. Take 1000 grams of corn stalks with a water content of 40% by weight, maintain a pressure of 1.6 MPa at 195° C. for 5 minutes, and then release the pressure to complete steam explosion. The resulting steam explosion product and water at 70°C were stirred and mixed for 30 minutes at a weight ratio of 1:3, and then solid-liquid separation was carried out ...

Embodiment 2

[0076] This example is used to illustrate the method of the present invention for preparing monosaccharides from cellulose-containing raw materials. Monosaccharides were prepared according to the method of Example 1, except that 1000 grams of corn stalks with a moisture content of 50% by weight were cut into small sections of 1.3 cm × 0.4 cm × 0.8 cm, and the Maintain for 4 minutes, then release the pressure, complete the steam explosion, stir and mix the obtained steam explosion product with water at 65°C according to the mass ratio of 1:2 for 40 minutes, then use a centrifugal pump LW400 type decanter centrifuge (manufactured by Zhangjiagang Huada Centrifuge) Co., Ltd.) carried out solid-liquid separation at a rotating speed of 900 rev / min, and obtained 2000 grams of steam explosion waste (moisture content is 75% by weight) in total.

[0077] According to the method for the steam explosion product of sulfuric acid hydrolysis by HPLC analysis described in Example 1, it is rec...

Embodiment 3

[0080] This example is used to illustrate the method of the present invention for preparing monosaccharides from cellulose-containing raw materials.

[0081] Monosaccharides were prepared according to the method of Example 1, except that 1000 grams of corn stalks with a water content of 35% by weight were cut into small sections of 1.2 cm × 0.4 cm × 0.7 cm, and the mixture was heated at 200 ° C under a pressure of 1.7 MPa. Hold for 6 minutes, then release the pressure to complete the steam explosion. Gained steam explosion product and 75 DEG C of water were stirred and mixed for 50 minutes according to the weight ratio of 1: 2.5, and then solidified at 900 rpm with a centrifugal pump LW400 type decanter centrifuge (Zhangjiagang Huada Centrifuge Manufacturing Co., Ltd.). The liquid was separated to obtain a total of 2000 g of solid steam explosion product (water content: 67.5% by weight).

[0082] According to the method for the steam explosion waste product of sulfuric acid h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com