Method for producing ultra-fine grain by using repeated forging of large deformation

An ultra-fine grain, large deformation technology, applied in the field of preparing ultra-fine grains by upsetting and extrusion large deformation, can solve the problems of cracks, billet tensile stress, etc., to eliminate cracks, deform uniformly, and reduce tensile stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

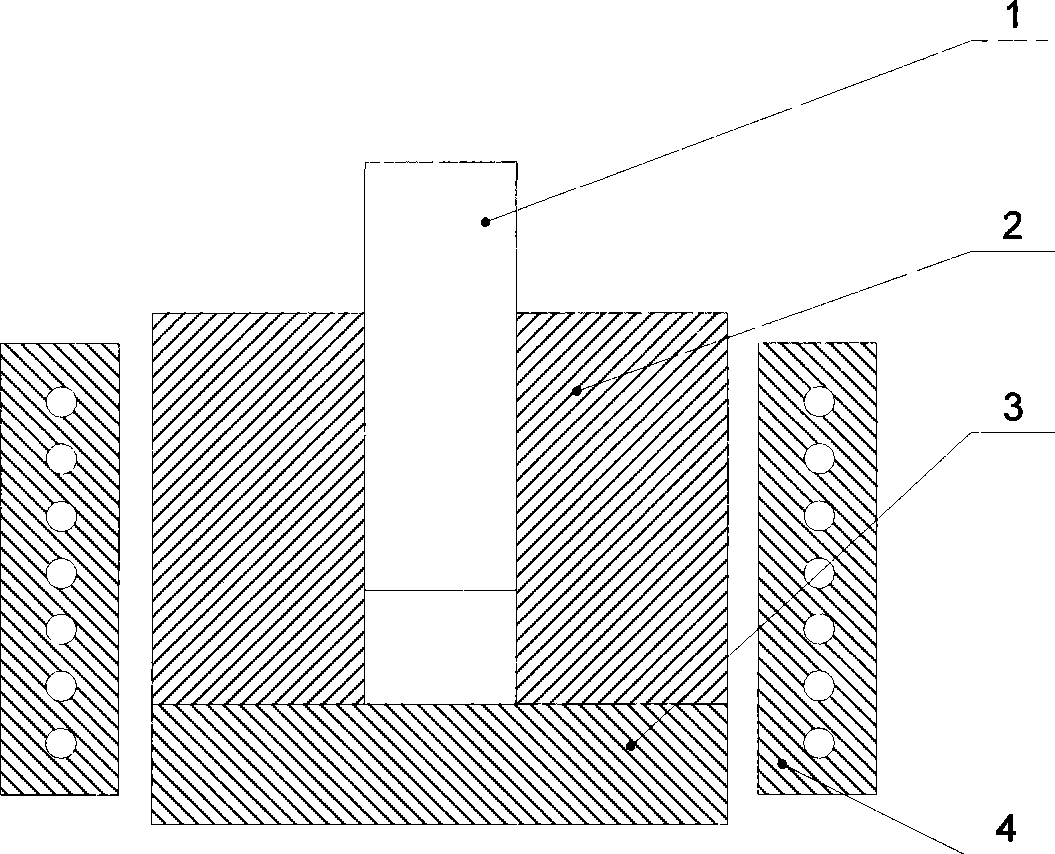

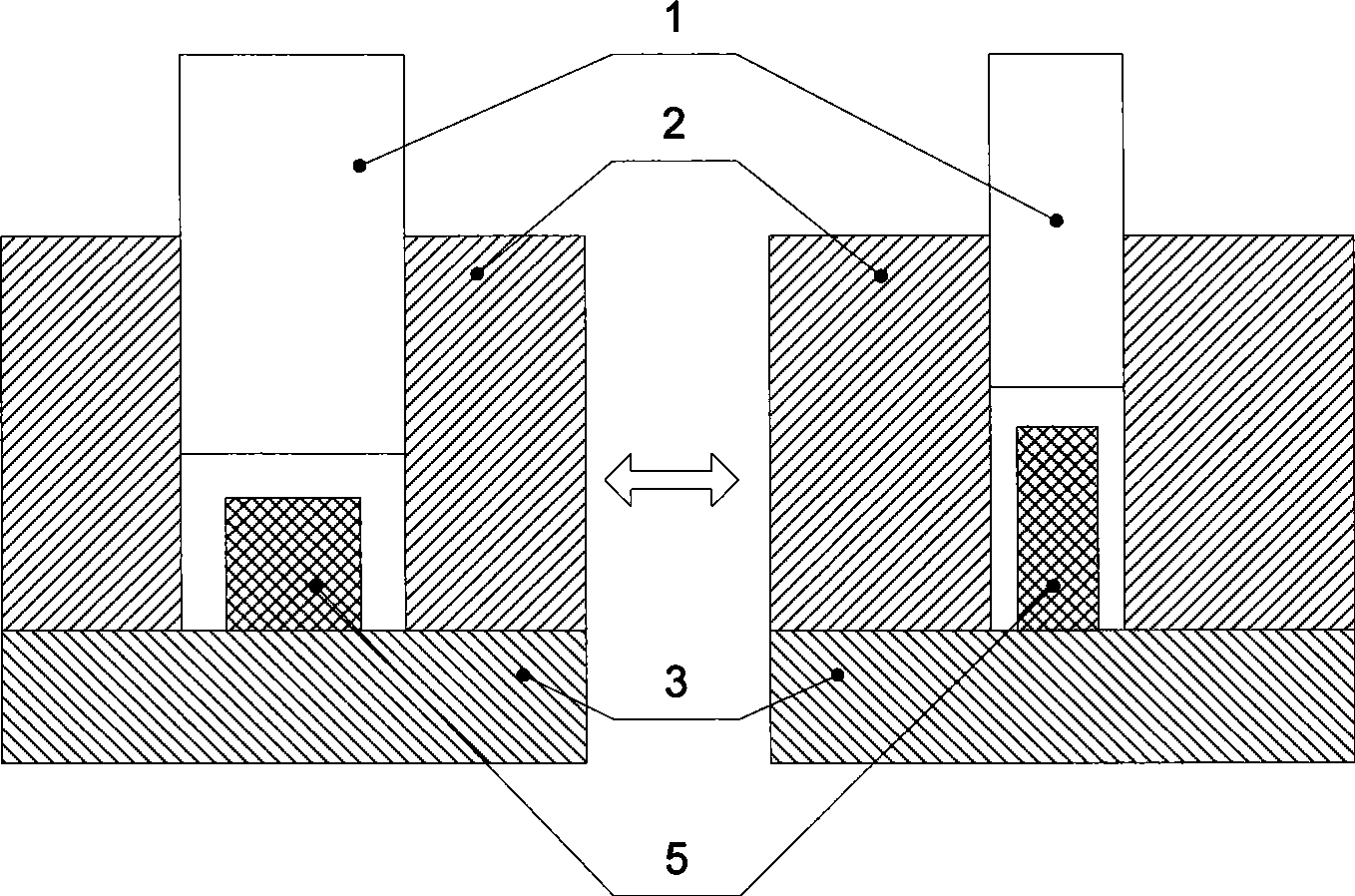

[0032] Example 1 Equipment for preparing ultra-fine grains using repeated upsetting and large deformation, including upsetting punch (1), upsetting die (2), upsetting punch (1) and upsetting die (2) connected Together, they are placed on the supporting pad (3). Combine two sets of molds with different cavity sizes, such as figure 2 As shown, two sets of molds are respectively fixed on the hydraulic press. The cross-sectional dimension of the mold 1 cavity is 10mm×13.3mm, and the cross-sectional dimension of the mold 2 cavity is 10mm×10mm.

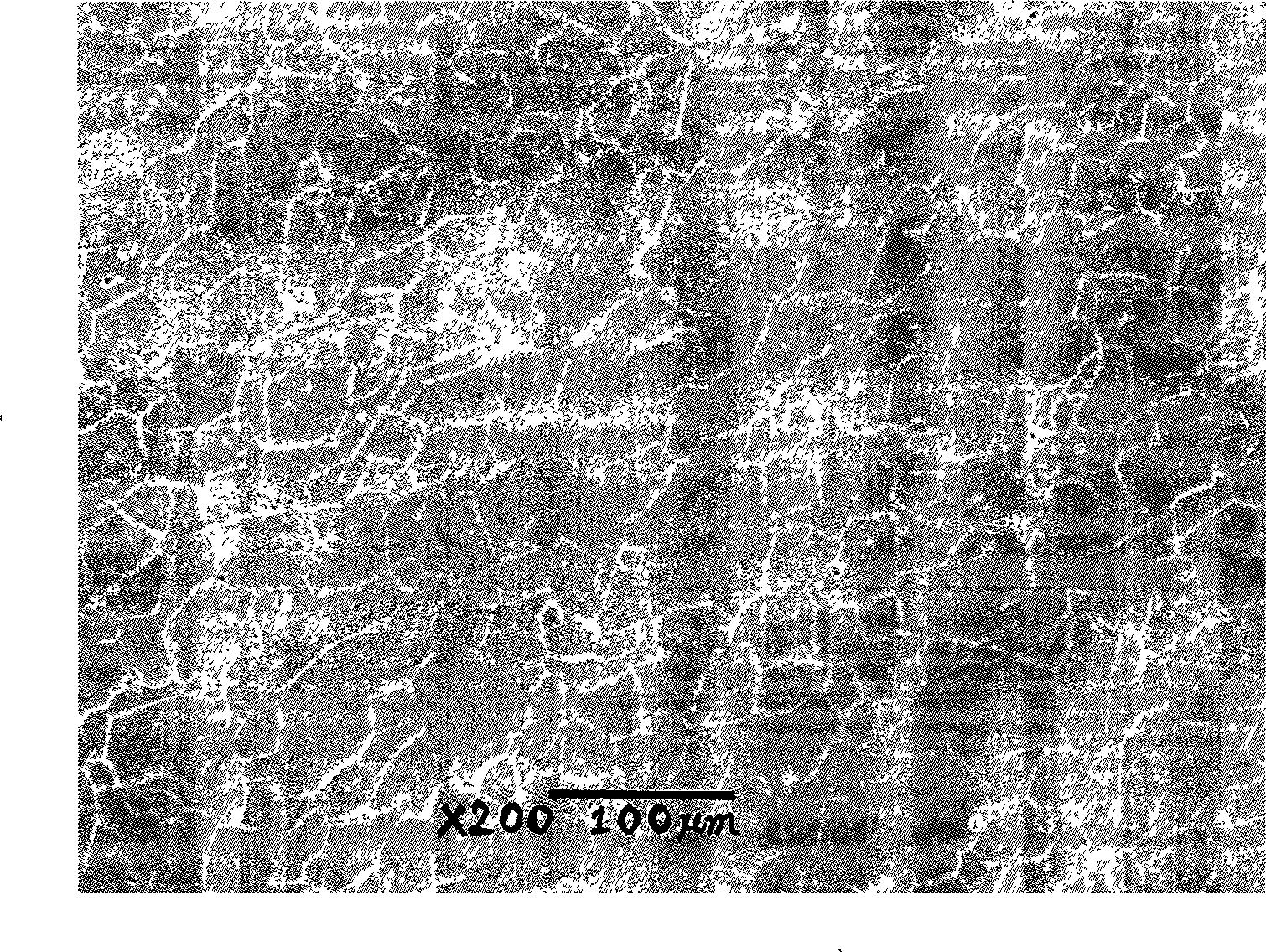

[0033] The pure copper blank (5) with an external dimension of 10mm×10mm×10mm is annealed in the heat treatment furnace to obtain a pure copper blank with a coarse-grained structure with a grain size of about 50-100 microns, as shown in Figure (3). Repeated upsetting process such as Figure 4 As shown, the blank (5) is placed in the upsetting die (2) of the first set of molds, and the upsetting punch (1) upsets the blank (5) downwards, so that ...

Embodiment 2

[0035] Example 2 The device for preparing ultra-fine grains by repeated upsetting and large deformation is fixed on a mechanical press to increase the pressing speed of the upsetting punch in order to increase the deformation rate of the blank.

[0036] The cross-sectional dimension of the mold 1 cavity is 10mm×11.1mm, and the cross-sectional dimension of the mold 2 cavity is 10mm×10mm. After annealing, the pure copper billet with an external dimension of 10mm×10mm×10mm is first placed in the upsetting die of the first set of molds, and the press of the upsetting punch is 1 mm, so that the blank fills the cavity of the upsetting die , The size of the blank after deformation is 10mm×11.1mm×9mm. After taking out the blank, rotate it 90 degrees, put it into the upsetting die of the second set of molds, press down 1.1 mm of the upsetting punch, so that the blank fills the upsetting cavity, the size of the blank after deformation is 10mm×10mm×10mm , And then rotate the deformed blank b...

Embodiment 3

[0037] Example 3 When the deformation temperature of the blank is relatively high, a correspondingly relatively high temperature of the upsetting die is used. The blank used in this embodiment is Q235, the size of the blank is 10mm×10mm×10mm, and the deformation is performed on a hydraulic press. The preheating temperature when the blank is first deformed is 600 degrees, and the heating temperature of the heating jacket is 400 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com