Dome sealing storage bunker

A coal storage bunker and dome technology, which is applied in the field of domed sealed coal storage bunkers, can solve the problems of heavy load on the central column, easy shaking, long cantilever, etc., achieve stable operation, avoid unsmooth operation, and improve the stress state Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

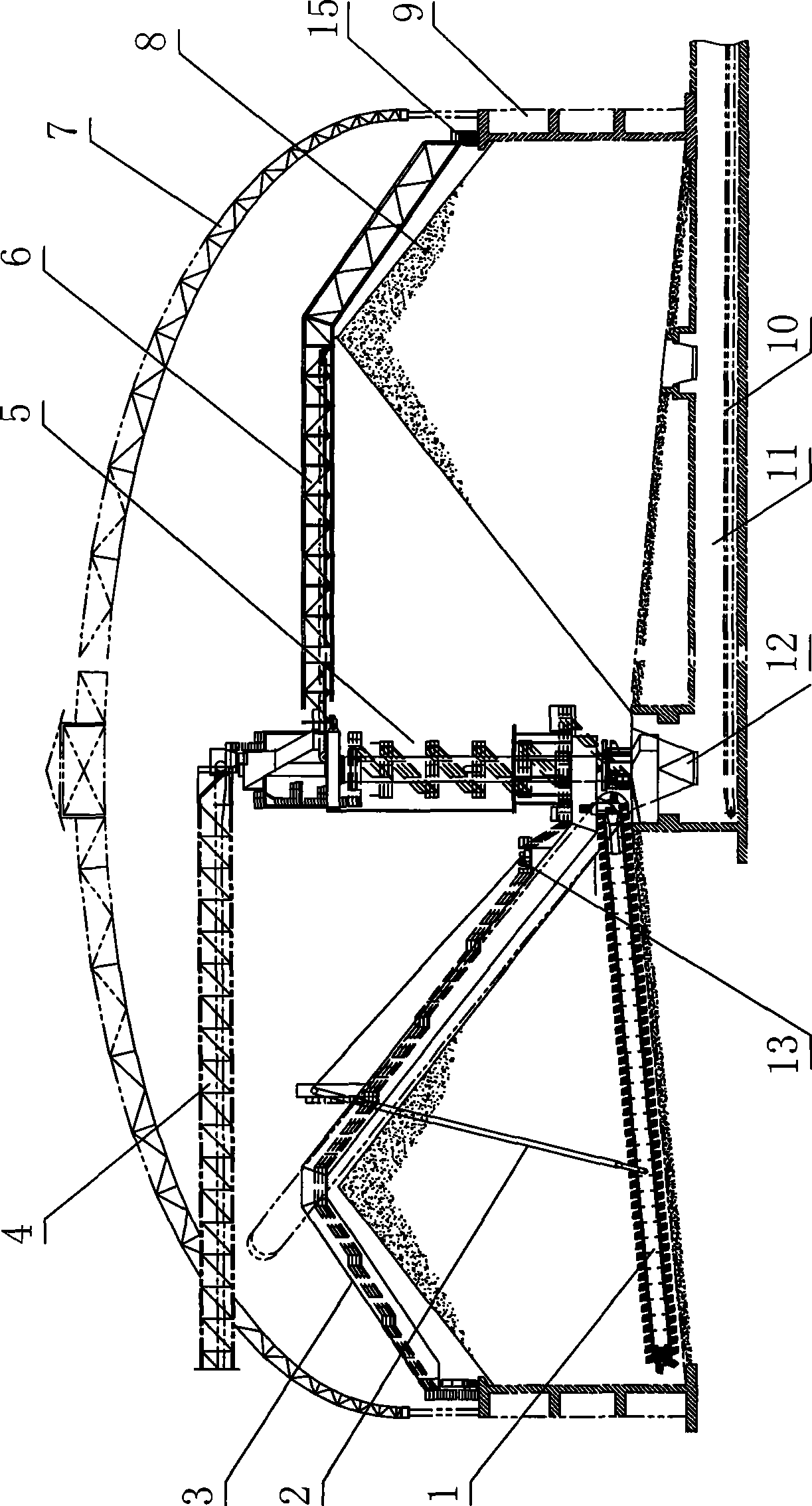

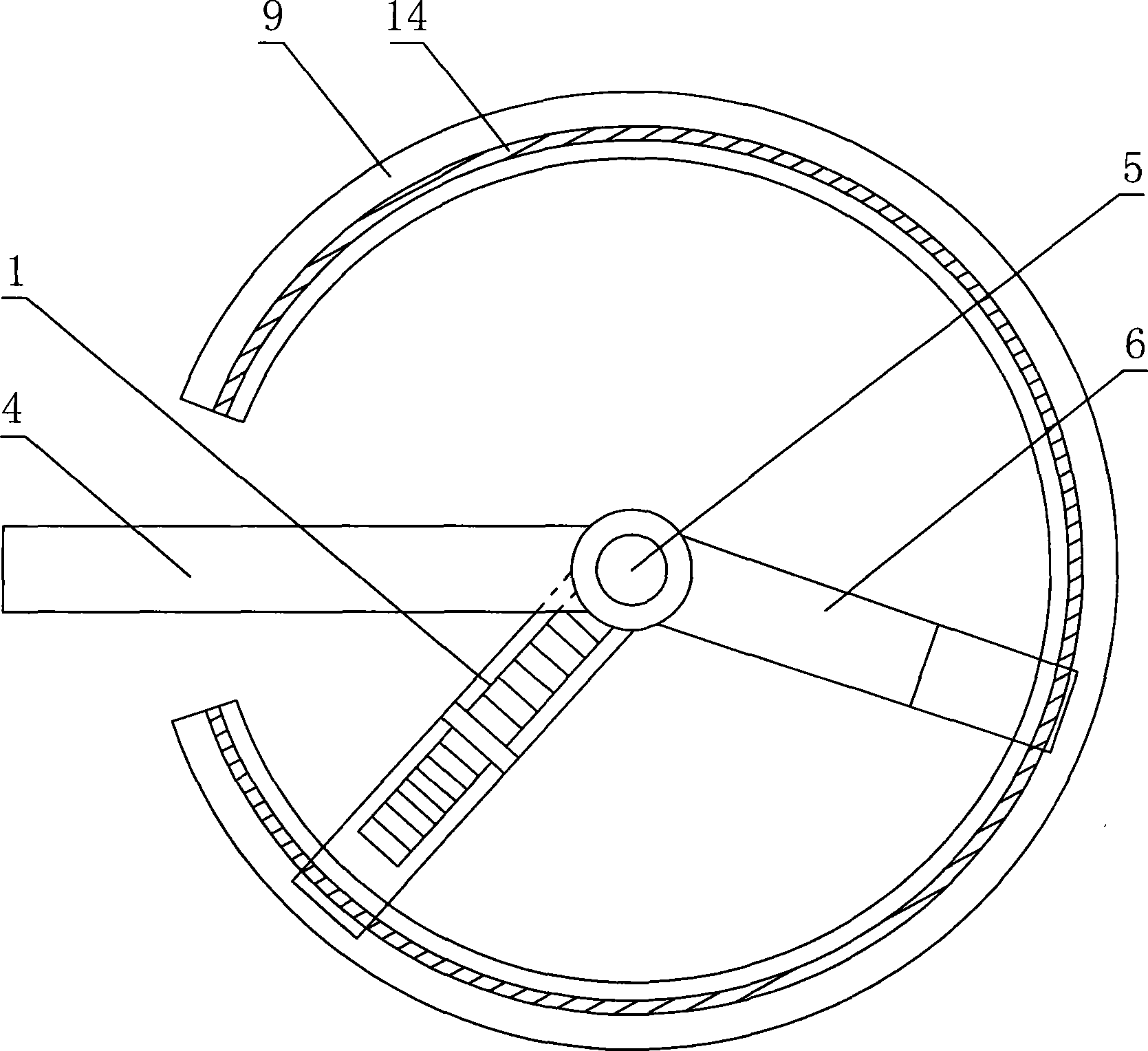

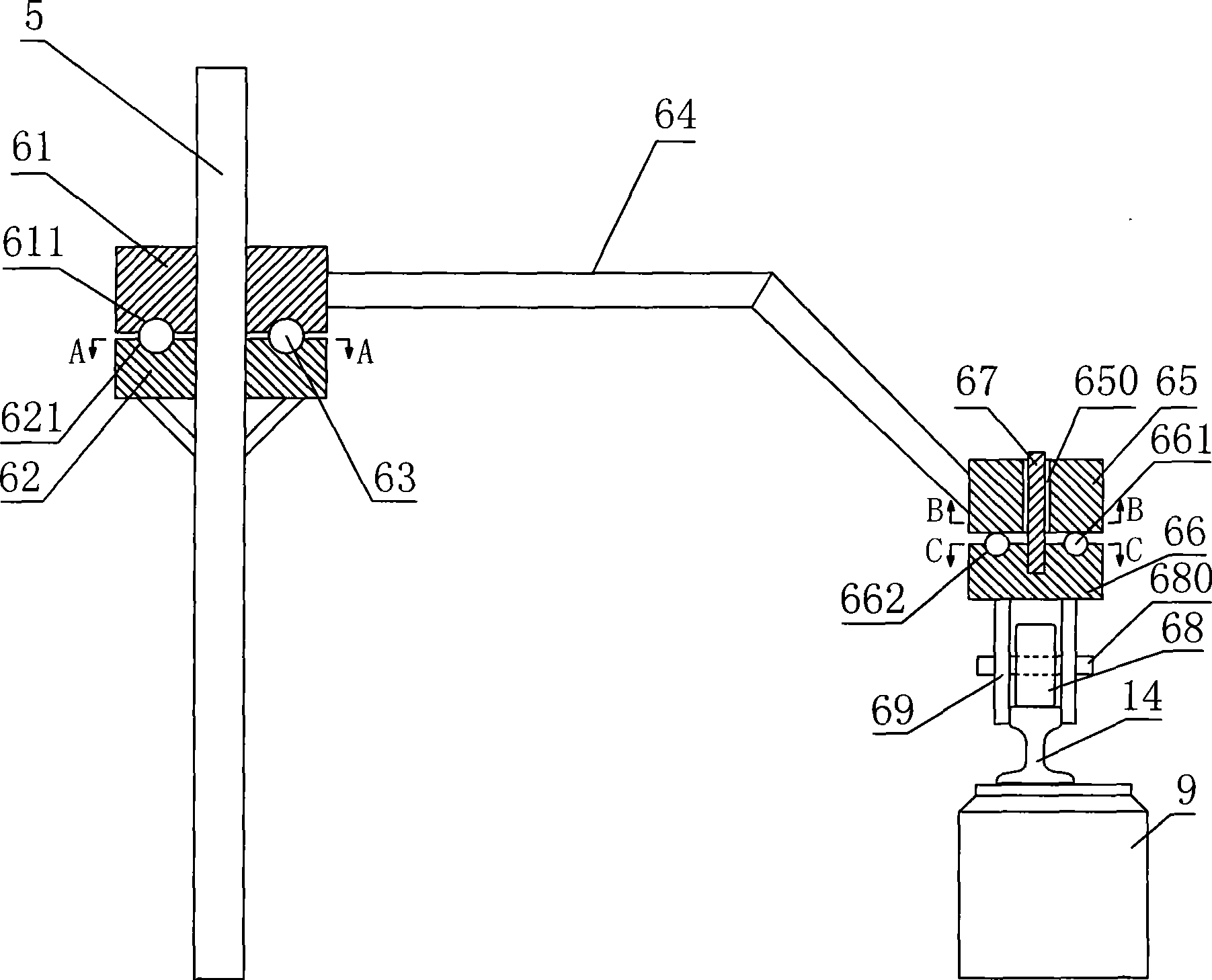

[0024] Example figure 1 with figure 2 As shown, a domed sealed coal storage bin includes a ceiling 7 and a retaining wall 9, and the ceiling 7 and the retaining wall 9 form a coal storage bin. The inner space of the coal storage bin is provided with a central column 5, and the center The column 5 is connected with a stacker 6 and a reclaimer 1, the upper end of the stacker 6 is provided with a feeder 4, the upper part of the retaining wall 9 is provided with a circular track 14, and the stacker 6 includes a stacker support 64 , the turntable 61 that is pivotally connected with the central column 5 at one end of the stacker support 64, and the mobile device 15 that can move on the circular track 14 at the other end of the stacker support 64, the stacker 6 Can rotate around central column 5. The material is transported to the stocker 6 through the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com