Hollow insulating glass

A heat-insulating glass and hollow technology, applied in the direction of parallel glass structures, shading screens, etc., can solve the problems of reducing the effect of air conditioning and cooling, waste of resources, and failure to solve heat insulation, etc., and achieve good noise reduction and heat insulation effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

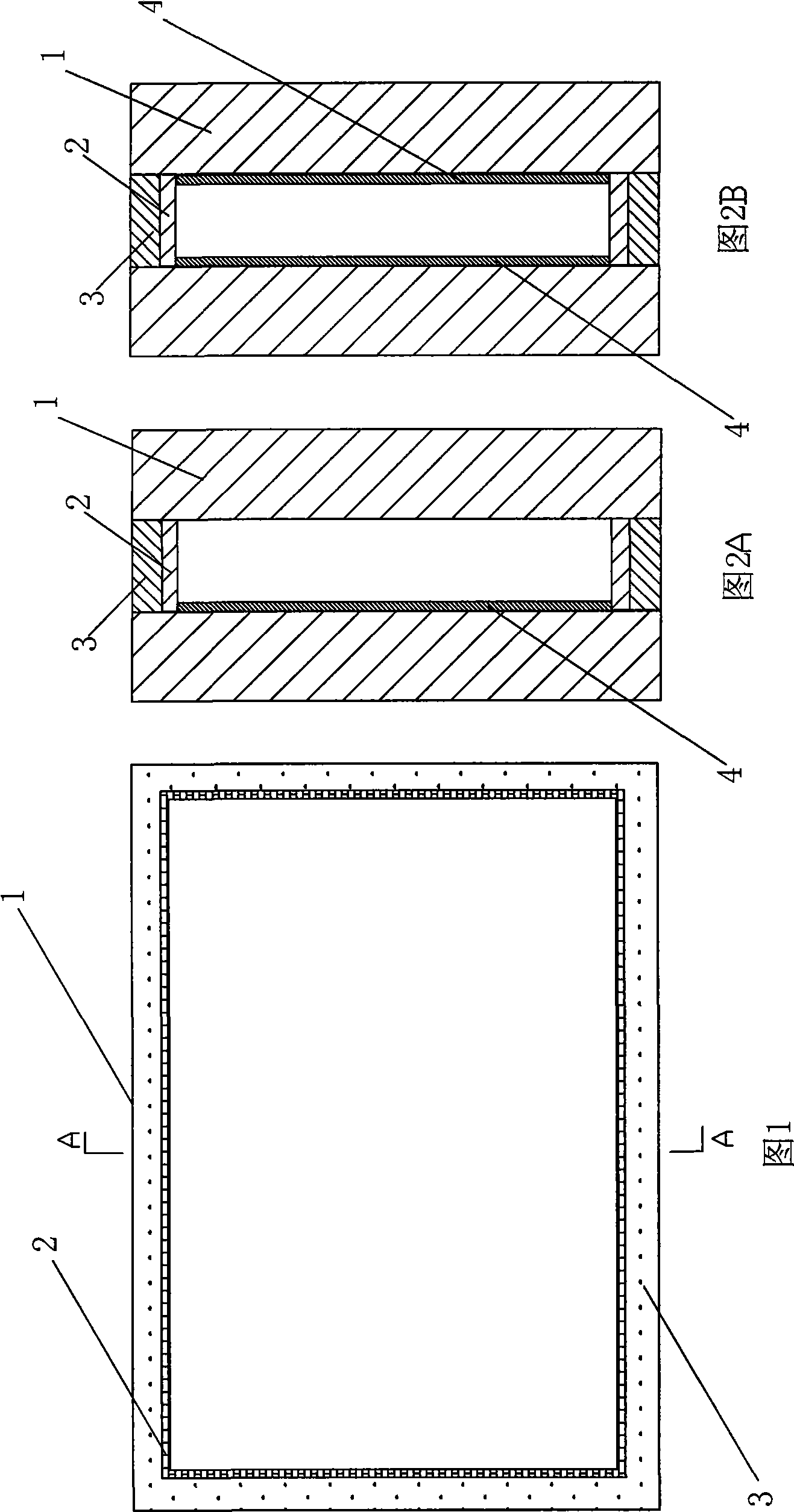

[0017] Embodiment 1: As shown in Figures 1 and 2, the insulating glass of this embodiment uses ordinary glass 1 as the substrate, adopts a double-layer superimposed structure, and sets an isolation frame 2 between the two layers of glass. The isolation frame can be Rectangular aluminum profiles, and between the two layers of glass, a sealant 3 is arranged on the periphery of the isolation frame to bond the two layers of glass together, and one of the opposite sides of the two layers of glass is sprayed with anti-ultraviolet and / or The coating 4 that penetrates the infrared rays, the specific production process is that the coating 4 is first sprayed on the ordinary glass 1, and about 12mm is left around the glass, and the aluminum profile is placed on the side of the glass with the coating 4 For the isolation frame 2, apply sealant 3 on the periphery of the isolation frame along the edges around the glass, then cover the isolation frame with another piece of common glass of the ...

Embodiment 2

[0018] Embodiment 2: As shown in Fig. 3, this embodiment is the same as Embodiment 1, and the difference is that a coating 4 is sprayed on two opposite faces of the two pieces of glass 1, which can be used for heat insulation and anti-ultraviolet, infrared Higher requirements occasions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com