Yarn quality measuring instrument and yarn winding machine

A measuring instrument and winding machine technology, which is applied in the field of winding machines to achieve the effect of strict quality inspection and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

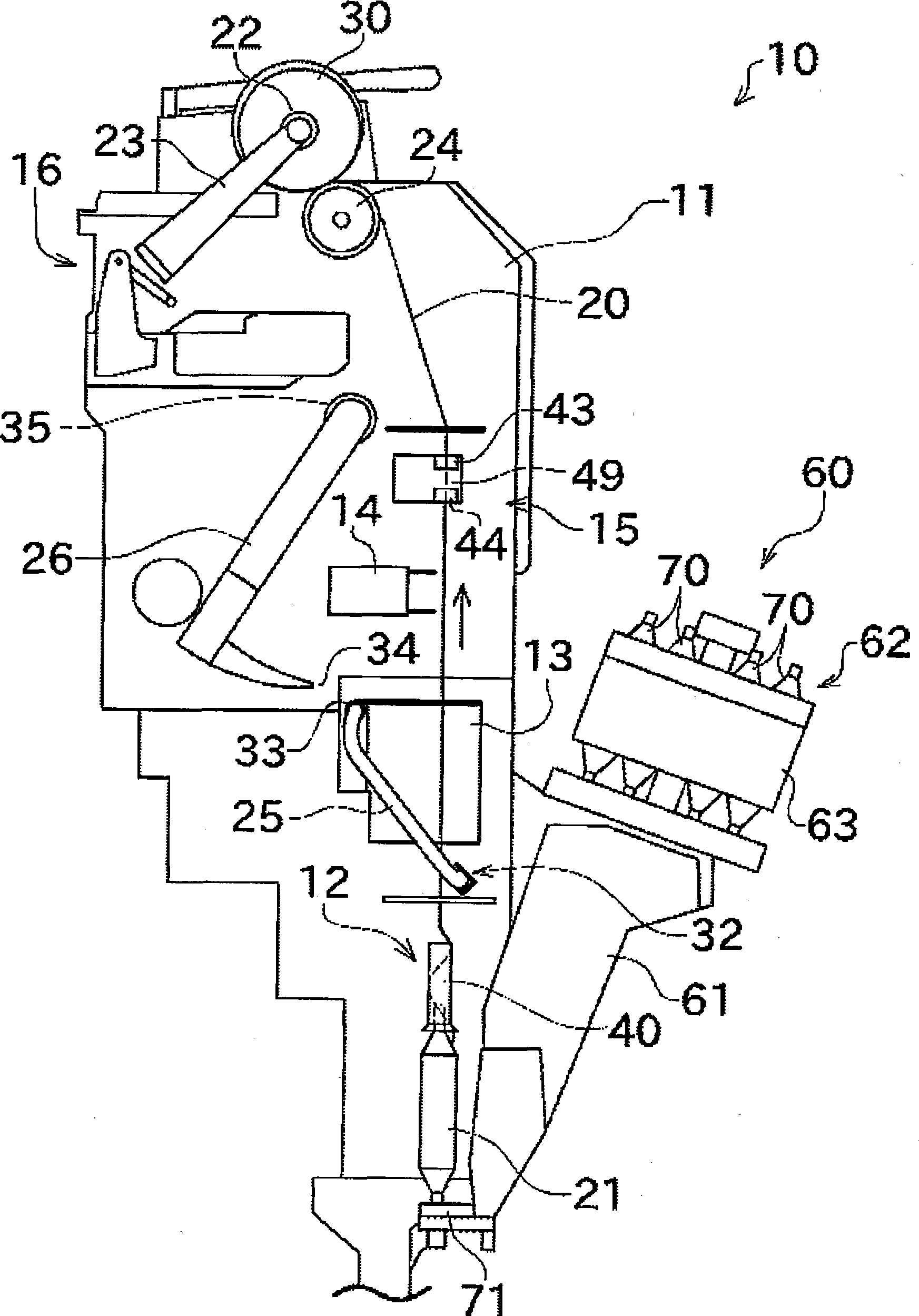

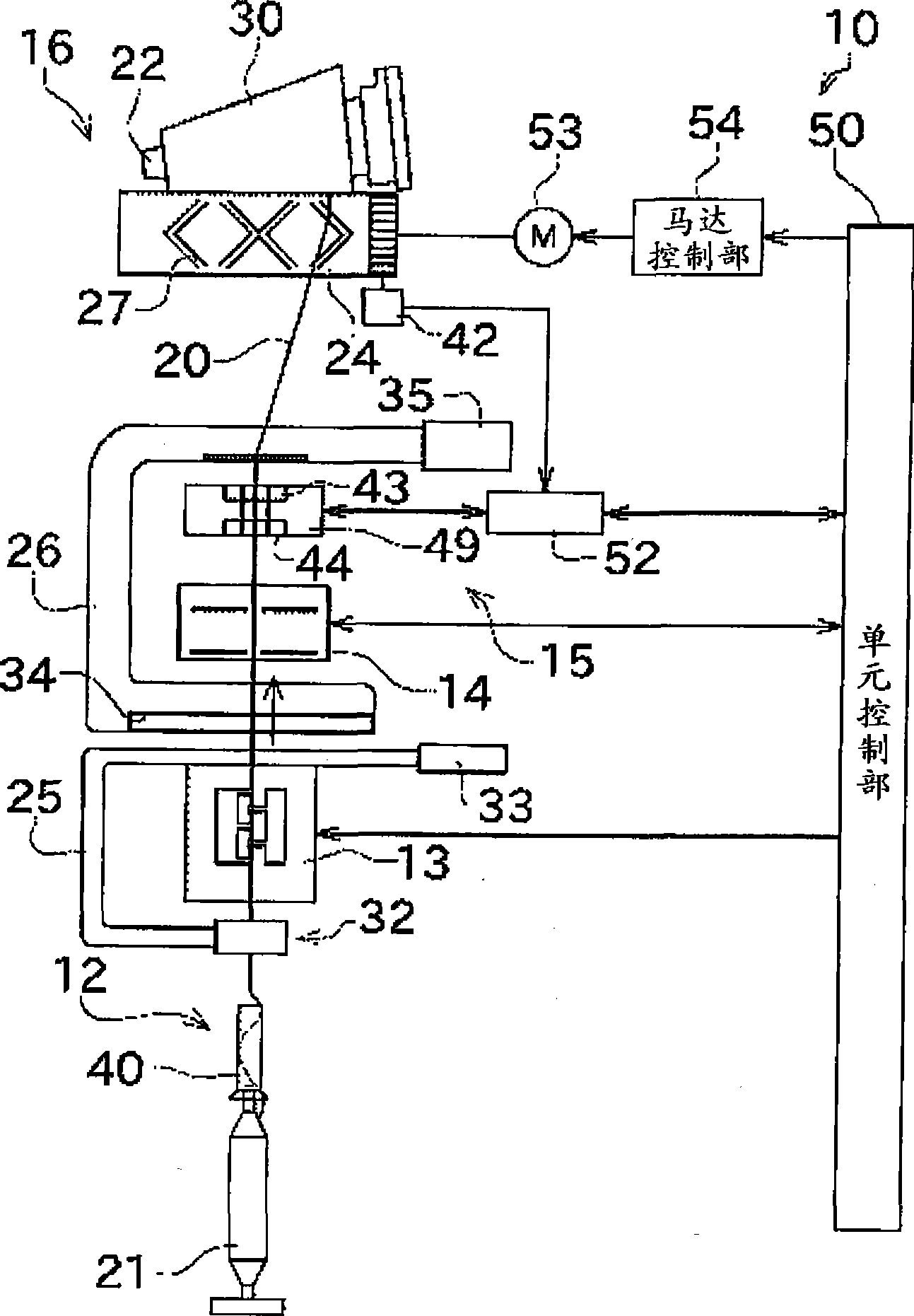

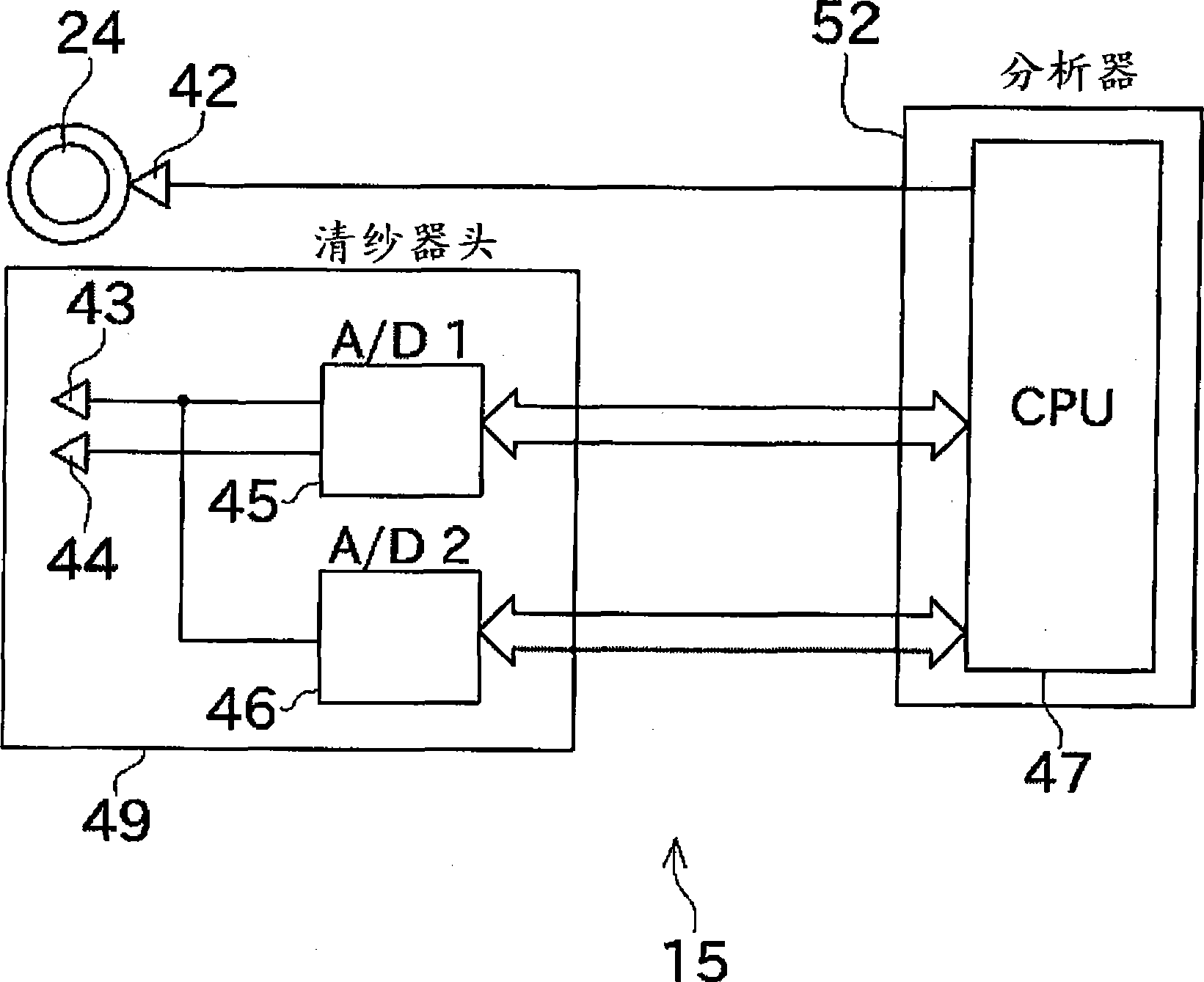

[0051] Next, preferred embodiments of the present invention will be described with reference to the drawings.

[0052] figure 1 as well as figure 2 The shown winder unit 10 winds the spun yarn 20 unwound from the yarn supplying bobbin 21 on the winding bobbin 22 while traversing, and forms a bobbin 30 of a predetermined shape with a predetermined length. The automatic winder (yarn winding device) of the present embodiment includes a plurality of winder units 10 arranged in parallel, and a machine control device (not shown) arranged at one end in the direction of the arrangement.

[0053] Each winder unit 10 is provided with: a unit frame 11 ( figure 1 ), and the winding unit main body 16 arranged on the side of the unit frame 11.

[0054] The winding unit main body 16 includes a cradle 23 and a winding drum (traversing drum) 24 . The cradle 23 can hold the winding bobbin 22 . The winding drum 24 traverses the spun yarn 20 and drives the above-mentioned winding bobbin 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com