Calibration device for gas alarm

A technology for gas alarms and calibration devices, which is applied in the direction of alarms, sampling devices, instruments, etc., can solve the problems of inability to accurately determine the target gas concentration, damage the operator's personal health, and reduce the accuracy of the alarm, so as to protect personal health, Effects of preventing environmental pollution and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

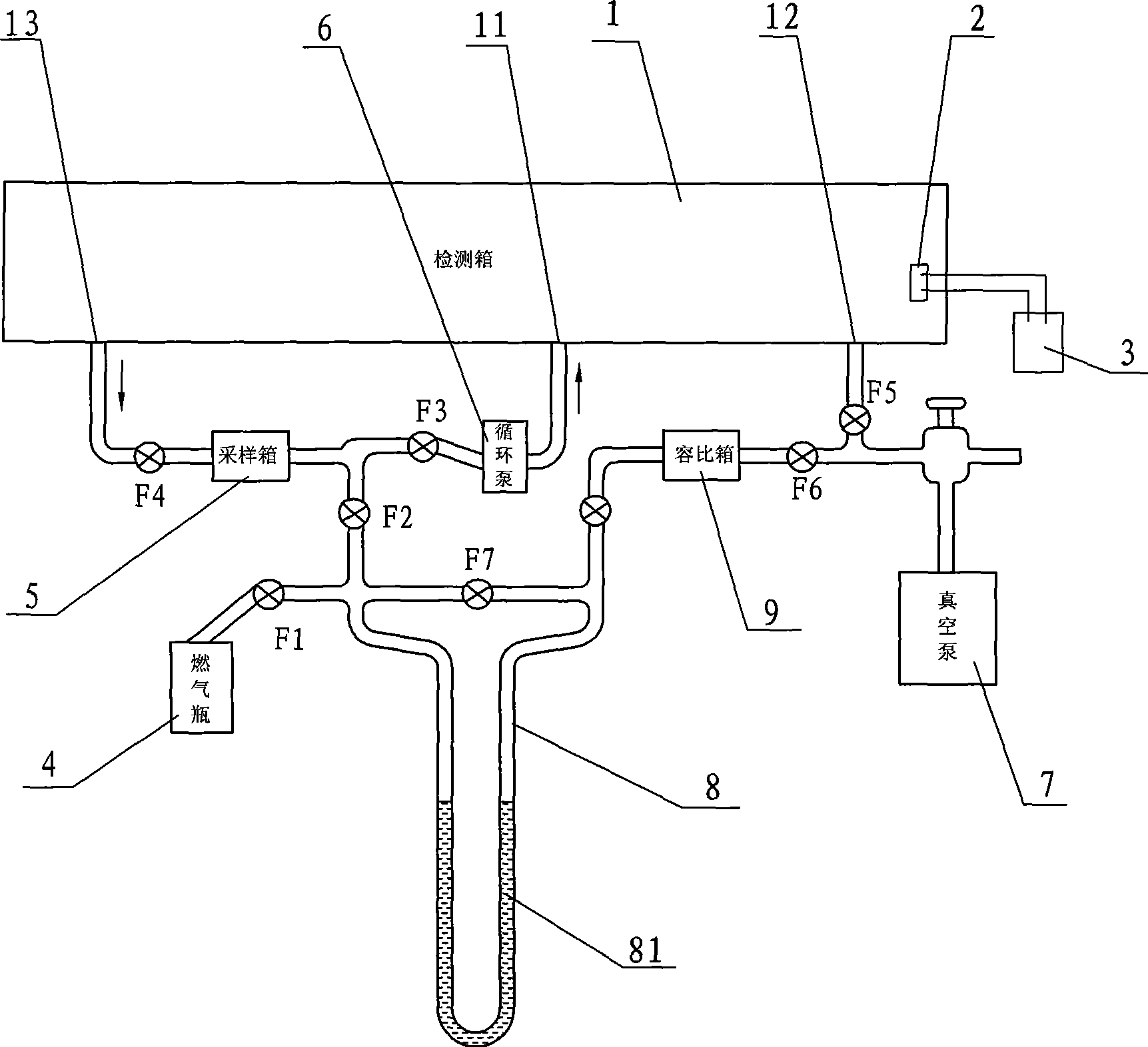

[0008] As shown in the figure, a detection box 1 is included, and the detection box is provided with a closable gas inlet 11 that can introduce target gas into the detection box and a closable exhaust port 12 that can discharge the gas in the detection box At least one gas sensor 2 for calibration with the same type and specification as the gas sensor of the gas alarm to be tested is arranged in the detection box, and the signal line of the gas sensor 2 for calibration is drawn out of the detection box. During the calibration process, the detection box is filled with a specific concentration of target gas, and the signal line of the calibration gas sensor 2 is connected to the signal input terminal of the burner alarm 3 to be calibrated, and the alarm start value of the gas alarm can be adjusted. Make it alarm the target gas higher than a specific concentration, and achieve the purpose of high-precision calibration. If multiple calibration gas sensors 2 are arranged in the det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com