Thermally conductive grease

A technology of grease and thermally conductive particles, used in the petroleum industry, semiconductor devices, thickeners, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

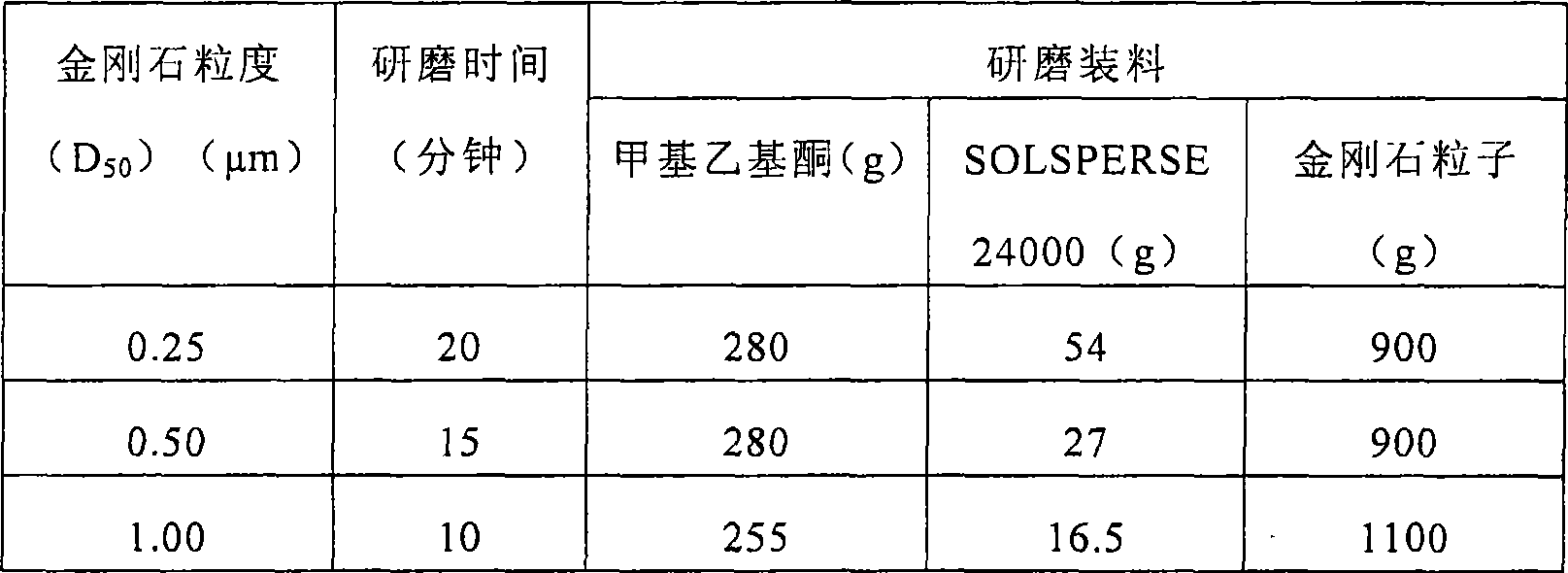

Method used

Image

Examples

example

[0047] Bulk thermal conductivity

[0048] Bulk thermal conductivity is typically determined on TCG samples according to ASTM D-5470-01 using a heat transfer tester from Custom Automation, Inc., Blaine, MN. The heat transfer tester was constructed in accordance with Proposal Number 3M-102204-01 and included the following components: Vision system capable of measuring parallelism and gap between copper gauge rods up to 0.010 inches (0.254mm) gap; copper gauge Rods with 5 Resistance Temperature Detector (RTD) sensors on each meter rod; coolers for cooling the cold adjustable compact (used to hold the cold meter rods) with an operating range of -20 to 100°C , and can maintain the coolant temperature to + / -0.02°C; 251bF load cell, installed on the X-Y micron adjustment position stage; cold adjustable pressure block (used to fix the cold instrument rod), installed on the load cell ; Thermally adjustable briquetting (used to fix the thermal instrument rod), heated by a thermal res...

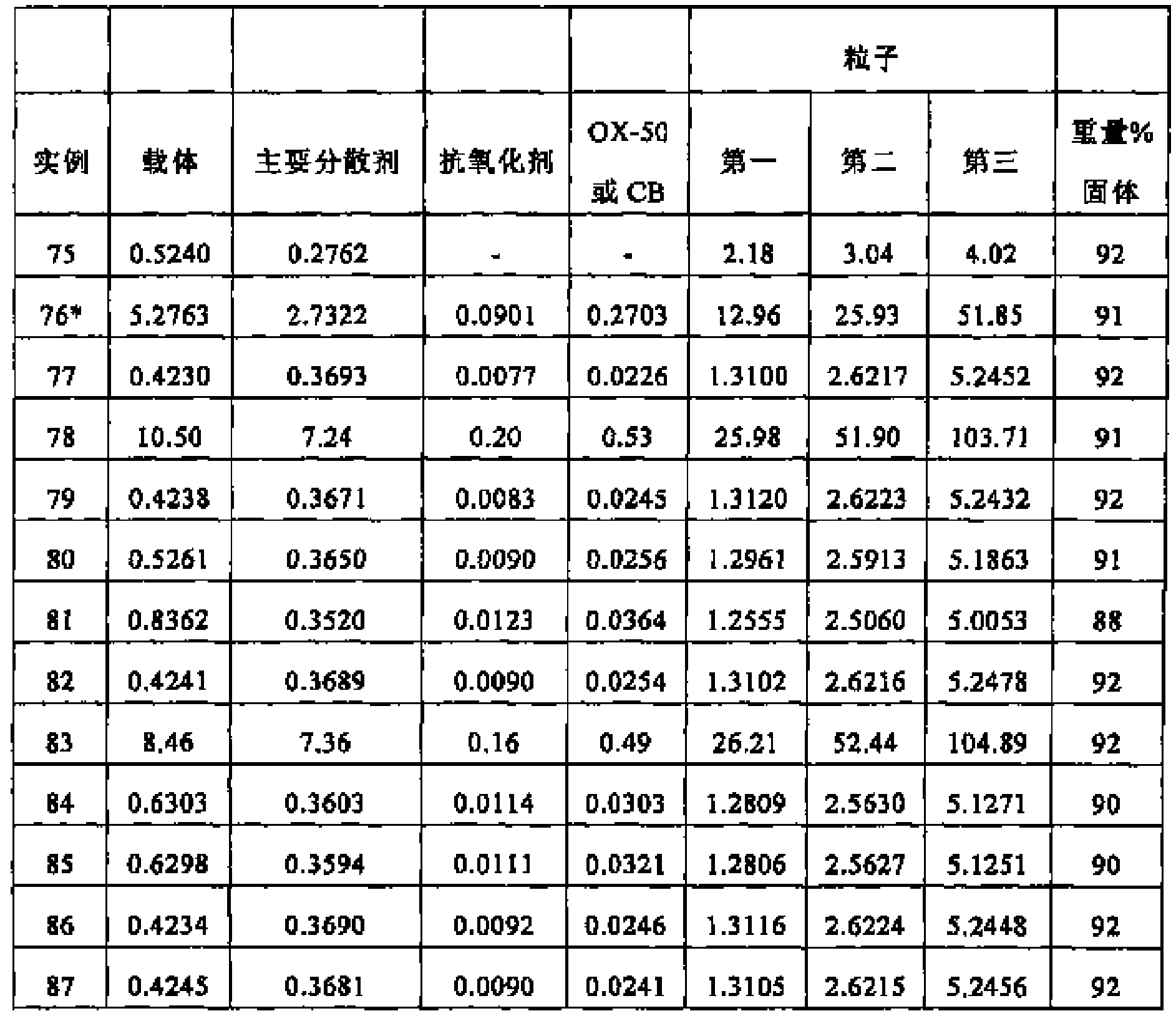

test ( example 75-85

[0051] Set the heater set point at 120°C and the cooler set point at -5°C, then allow the elements to equilibrate. The instrument bar gap after thermal equilibration was mechanically adjusted to about 400 microns. The surfaces of the hot and cold rods were brought coplanar using the turnbuckles of each rod until the gap between the rods read by each of the three independent cameras fell within + / - 3 μm.

[0052] The excess of each tested TCG sample was placed on the surface of the hot gauge stick and smoothed over the entire surface. The head is then closed and clamped in place by pressing down on the head with about 10 lbs of force (4.5 kg force), allowing excess TCG sample to seep out of the gauge stick gap until it reaches the mechanical stop. Wipe off the excess TCG with a paper towel or muslin and clean the pins of the gauge stick to facilitate accurate gap measurement by the three vision cameras. Allow the meter to equilibrate for approximately 10 minutes before contin...

example 1

[0083] The compositions of Examples 1 to 64 are shown in Table 1. The compositions of Examples A to N and 65 to 74 are shown in Table 2. Table 3 shows the data obtained from bulk thermal conductivity and thermal impedance measurements performed for selected examples. Table 4 shows viscosity data for selected examples.

[0084] Table 1

[0085] example

[0086] example

[0087] example

[0088] example

[0089] example

[0090] example

[0091] example

[0092] example

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com