Concrete mixer truck

A technology for mixing trucks and concrete, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc. The effect of mixing and transporting capacity and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The concrete technical scheme of the present invention will be further described below in conjunction with embodiment:

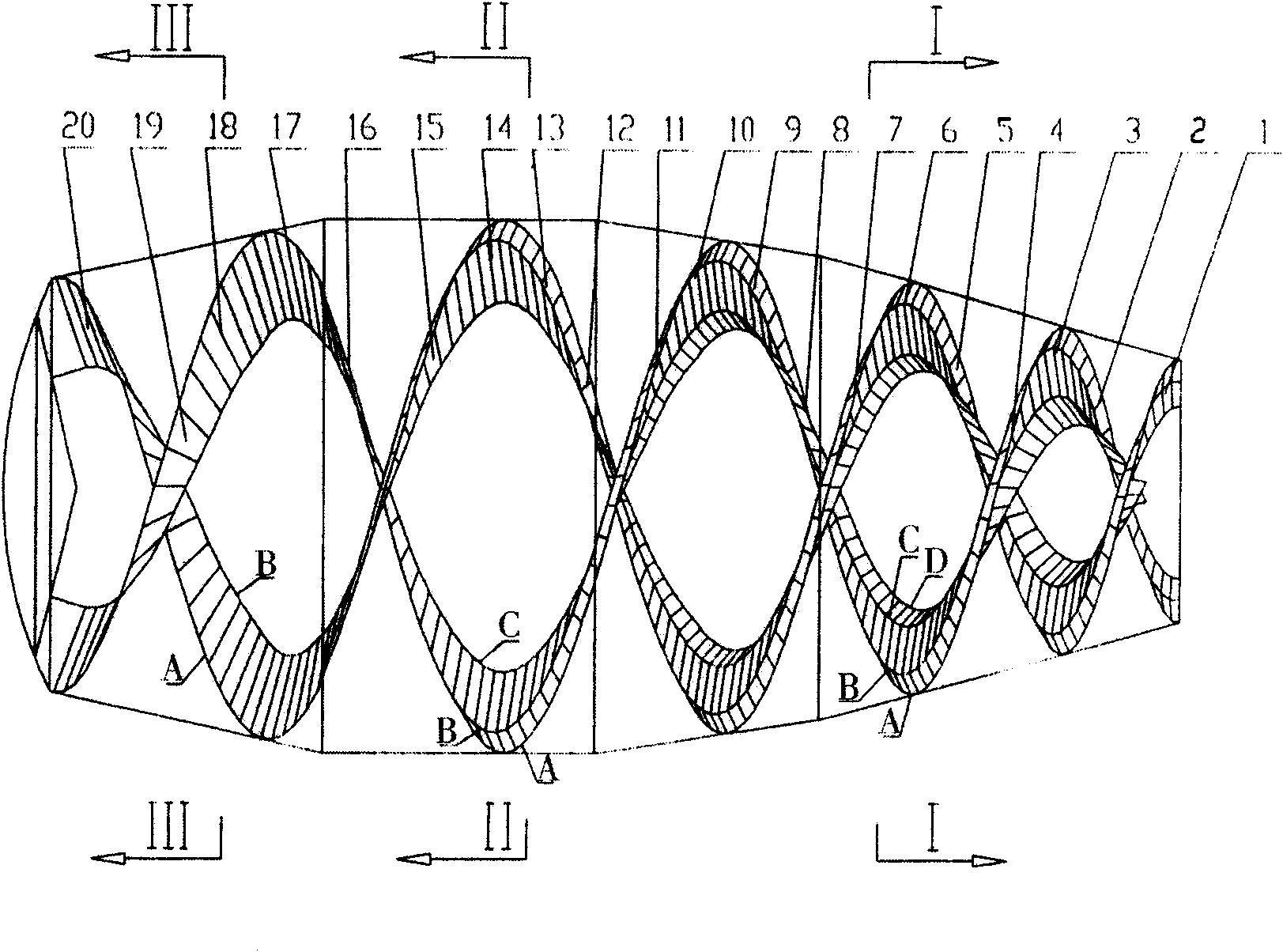

[0021] Figure 1~ Figure 4 As shown, the tank body of the mixing tank of this concrete mixer truck is composed of a feed cone section, a cylindrical section, and a tank bottom cone section. The mixing blades are composed of 20 double-helical blades with different geometric sizes and installation angles. The seams of each blade are butt welded, of which

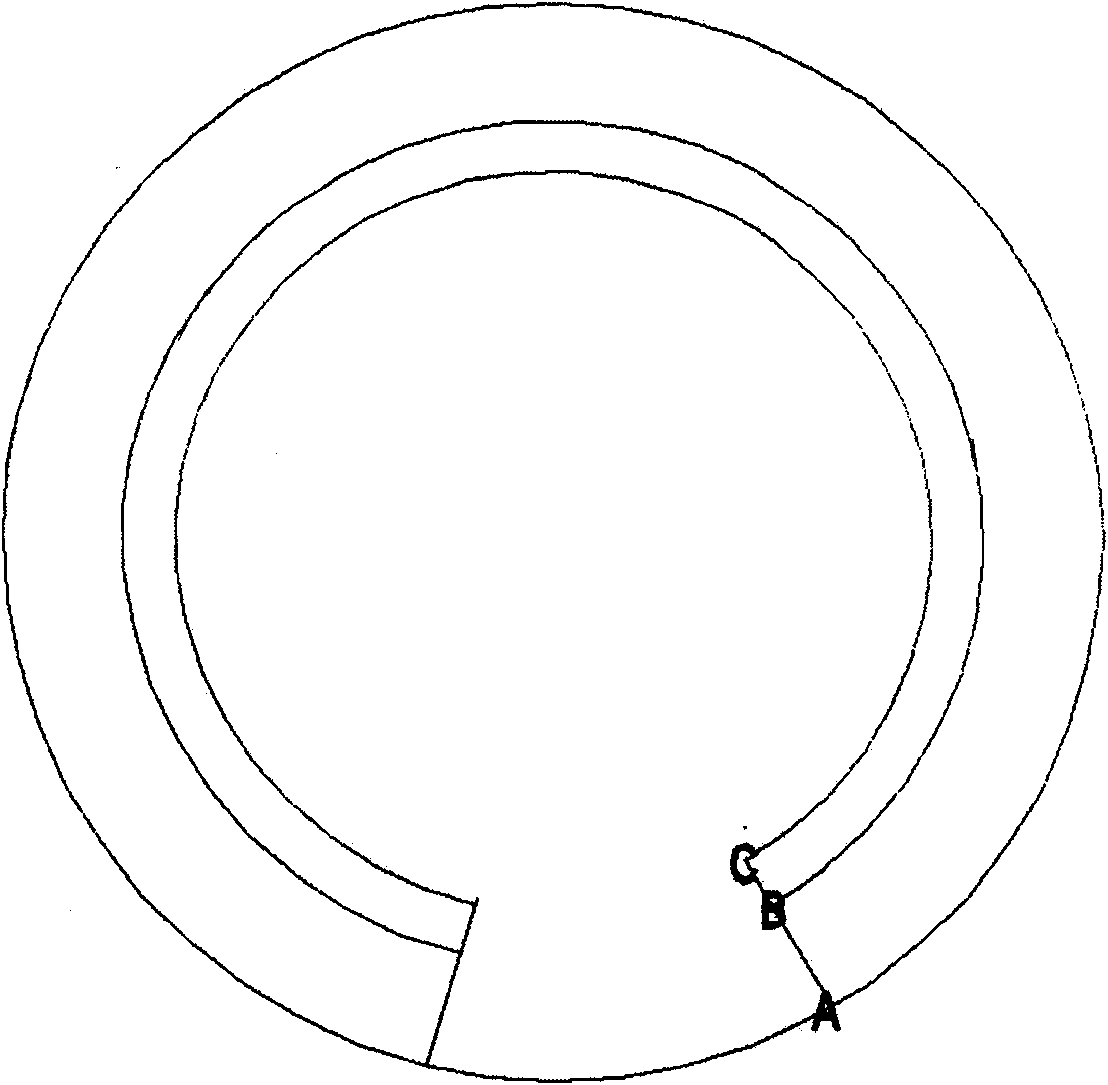

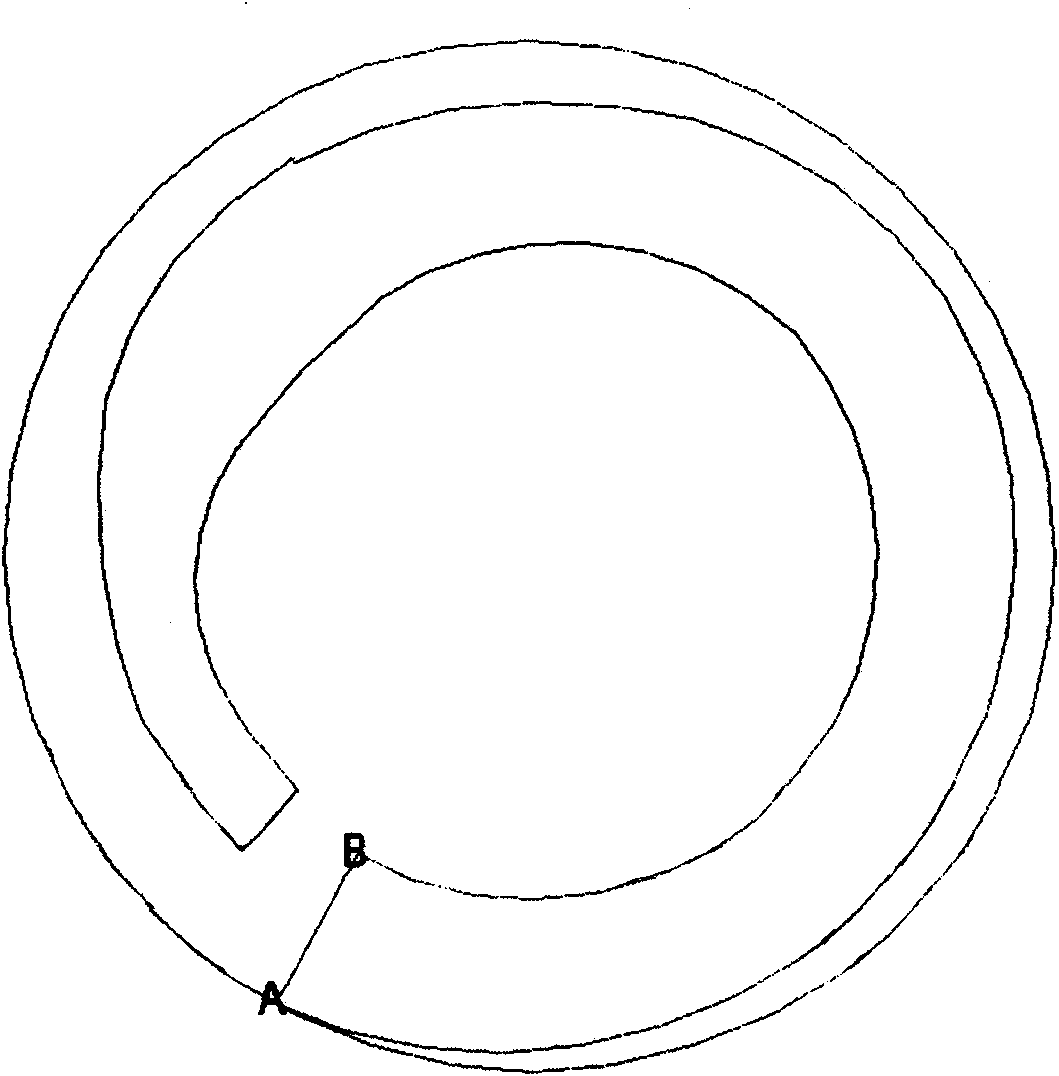

[0022] Blades 1 to 11 constitute the blades of the feeding cone section. Viewed from the direction of the tank axis, the four trajectory lines A, B, C, and D of the helical blade form a concave surface with two inflection points (see Figure 2). Blades 1 to 11 The shapes of the blades are similar, but there are differences in geometric dimensions and installation angles, which can ensure the smooth and rapid feeding and discharging of dry concrete. The blades of each blade are processed with different...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap