Retreaded tyre vulcanization die

A technology for retreading tires and vulcanizing molds, which is applied in the field of rubber machinery. It can solve the problems of unreasonable heating form and cavity design, and achieve the effects of reducing radiation heat transfer, heating up quickly, and avoiding heat conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

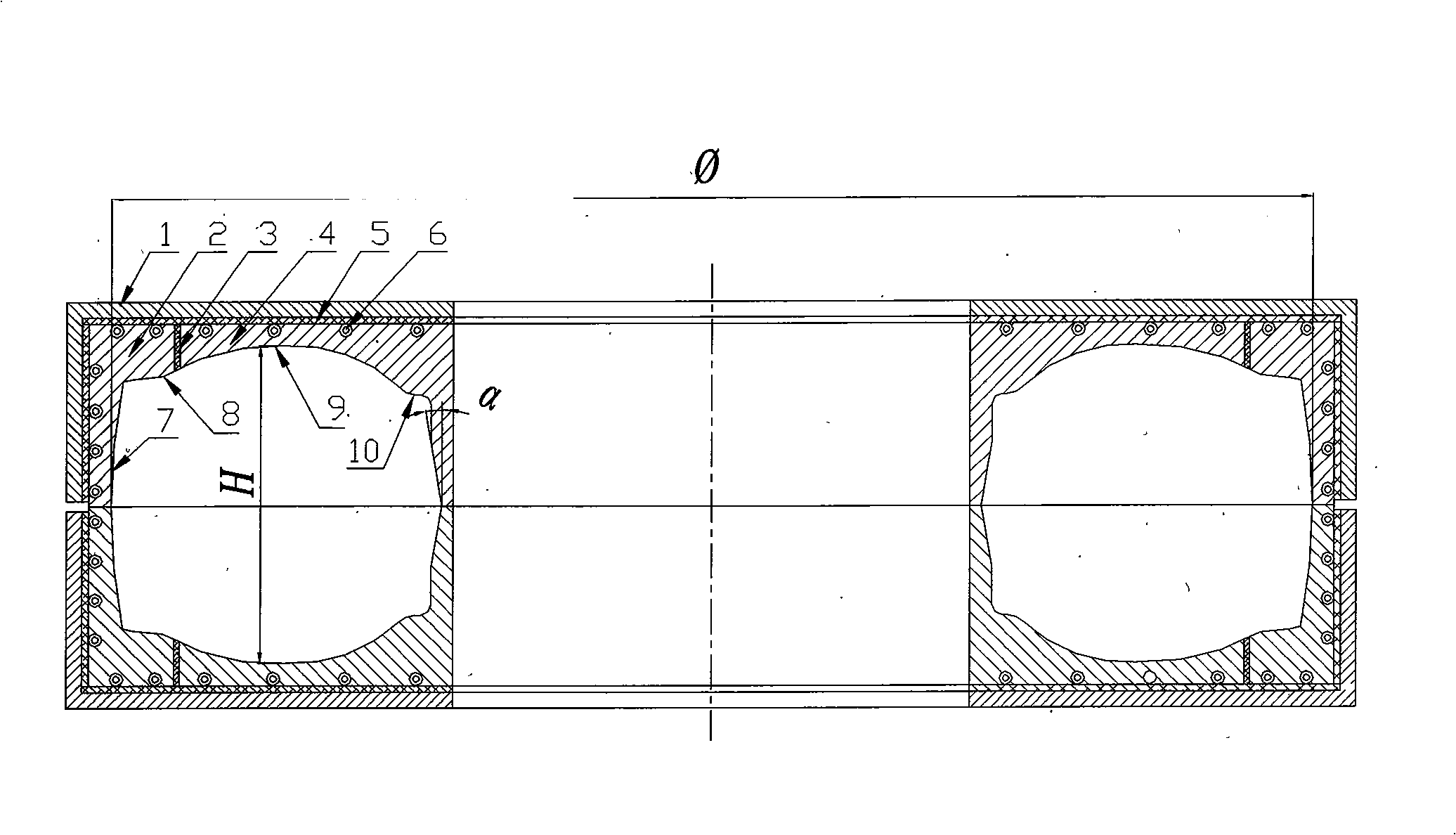

[0026] Embodiment, as shown in the figure, the 11.00R20 retreaded tire vulcanization mold is divided into an upper mold and a lower mold, and the mold shell 1 is made of a steel plate with a thickness greater than 12mm, which can constrain the mold liner and bear the pressure of the vulcanized tire together with the liner. Several reinforcing ribs are welded on the shell, and the outside is wrapped with an insulating layer. The shell 1 of the upper die is also welded with several locking bolt seats and the jacking cylinder frame for opening the upper die, etc., and the bottom surface of the shell 1 of the lower die is provided with a mold support and a locking bolt frame corresponding to the upper die.

[0027] The crown liner 2 and the sidewall toe liner 4 made of aluminum alloy are fastened on the casing 1, and there is a heat insulation gap 3 between the crown liner 2 and the sidewall toe liner 4, and the insulation The thermal gap 3 has a width of 2 mm and is filled with h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com