Surface coarsening LED chip and manufacturing method thereof

A technology for light-emitting diodes and surface roughening, which is applied in the fields of light-emitting diode chips, chip manufacturing, and light-emitting diode chip manufacturing. It can solve the problem of heat dissipation of high-power light-emitting diodes and improve light efficiency. Low efficiency and other problems, to avoid visible light resonance, improve external quantum efficiency, and reduce the number of total reflections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will now be described in detail by way of examples with reference to the accompanying drawings.

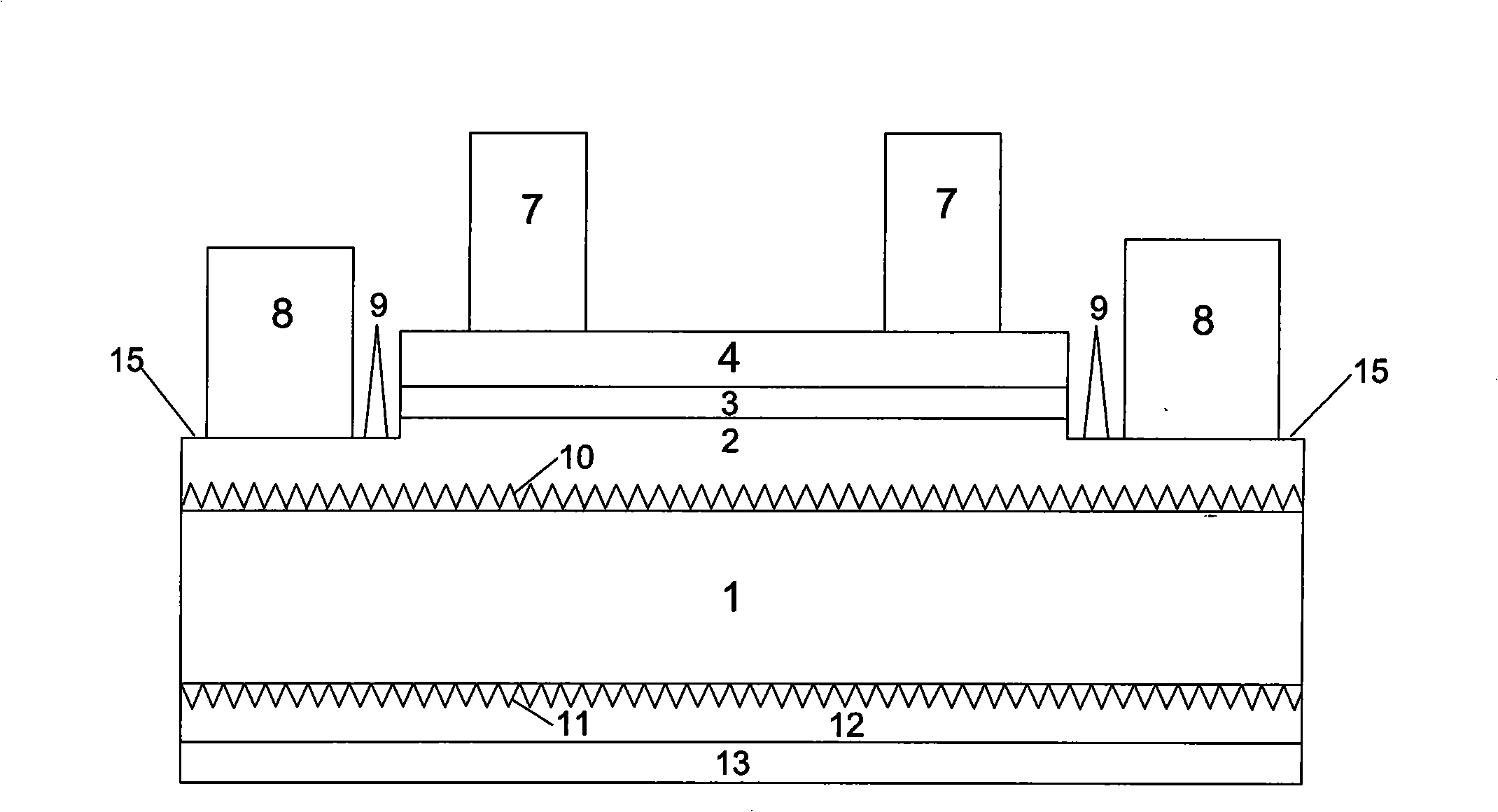

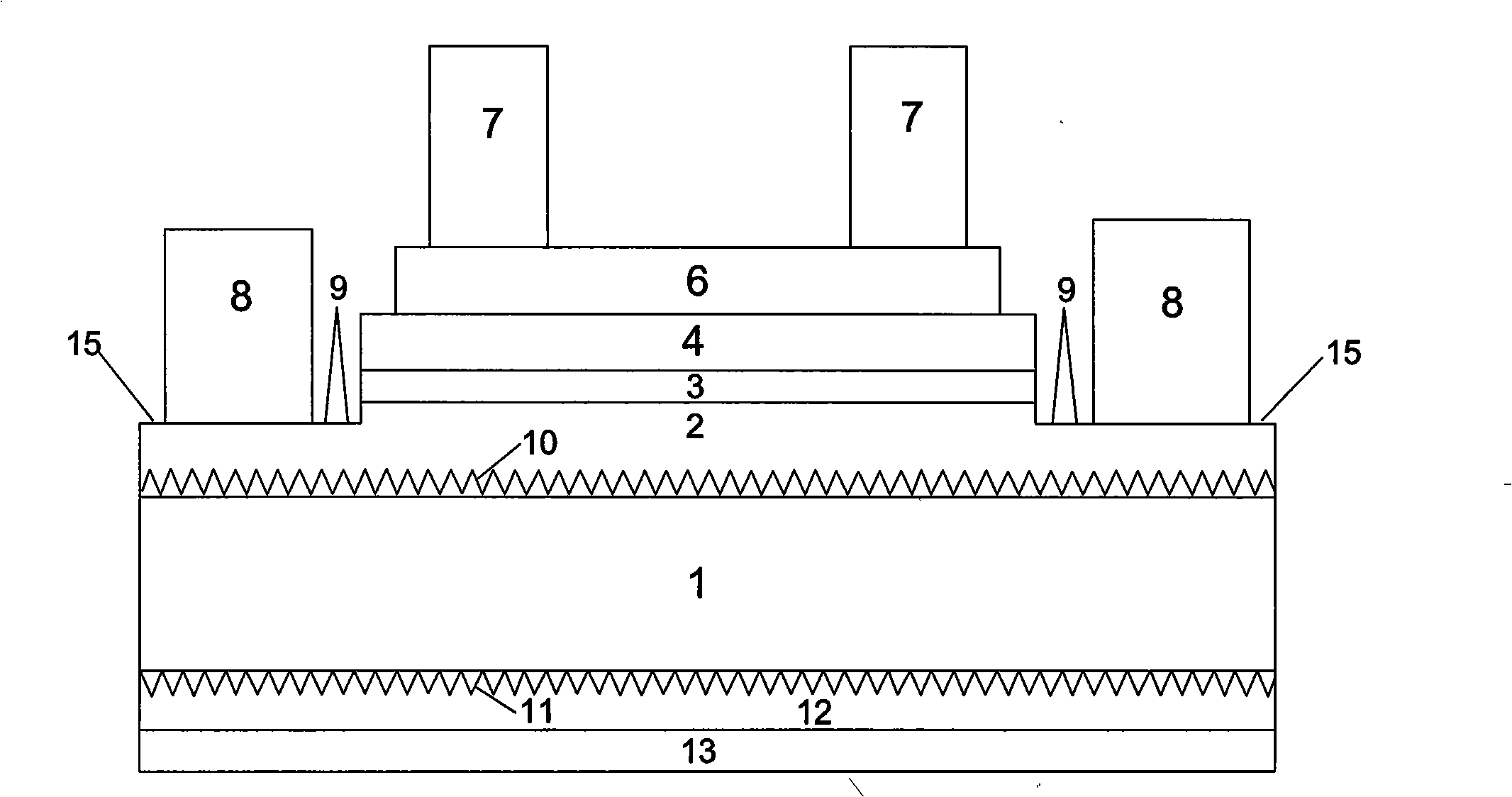

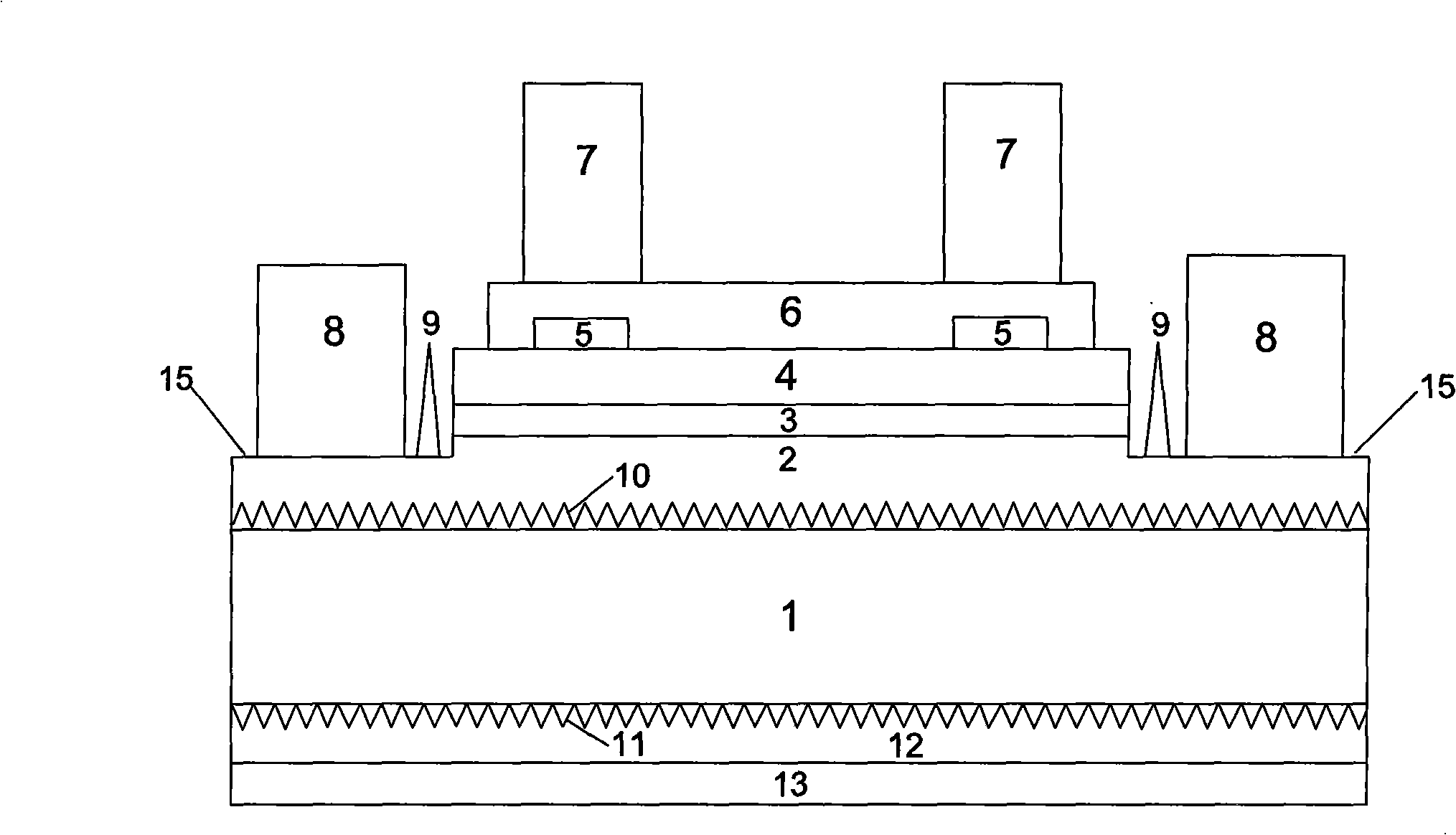

[0038] The first specific example is figure 1 and Figure 5As shown, the light-emitting diode chip of the present invention includes a substrate 1, an n-type semiconductor layer 2 formed on the front surface of the substrate 1, a light-emitting layer 3 formed on the n-type semiconductor layer 2, and a p-type semiconductor layer formed on the light-emitting layer 3. The semiconductor layer 4, the negative electrode bonding wire region 15 formed by etching on the n-type semiconductor layer 2, the positive electrode metal layer 7 formed on the p-type semiconductor layer 4, and the negative electrode metal layer formed on the negative electrode bonding wire region 15 layer 8, a conical optical microstructure 10 is provided on the front of the substrate 1, a conical optical microstructure 11 is provided on the back side of the substrate 1, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com