Light-emitting diode and back light module

A technology of light-emitting diodes and backlight modules, which is applied in the direction of electrical components, electrical solid-state devices, circuits, etc., can solve the problems of inconsistency, poor light mixing effect, and increase the overall thickness of the original light strip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

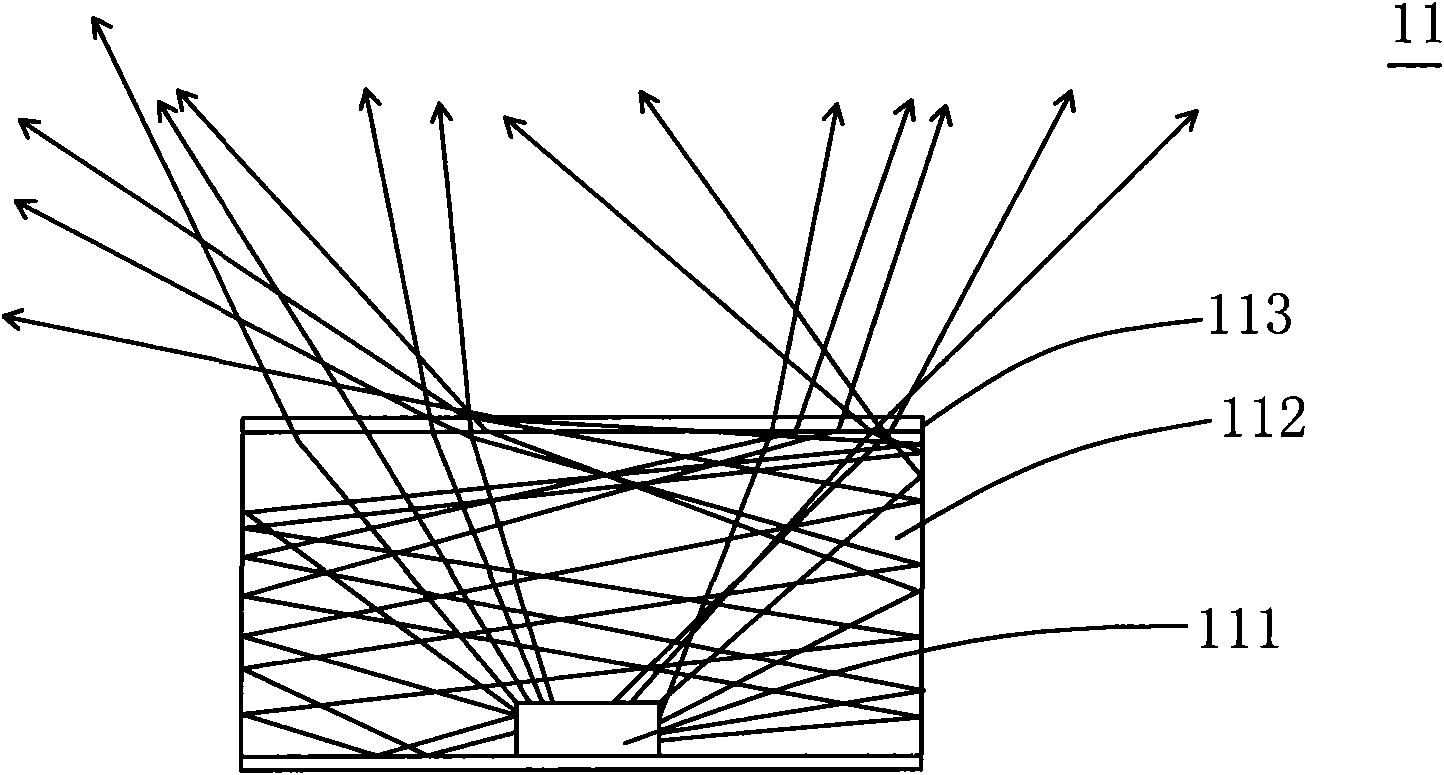

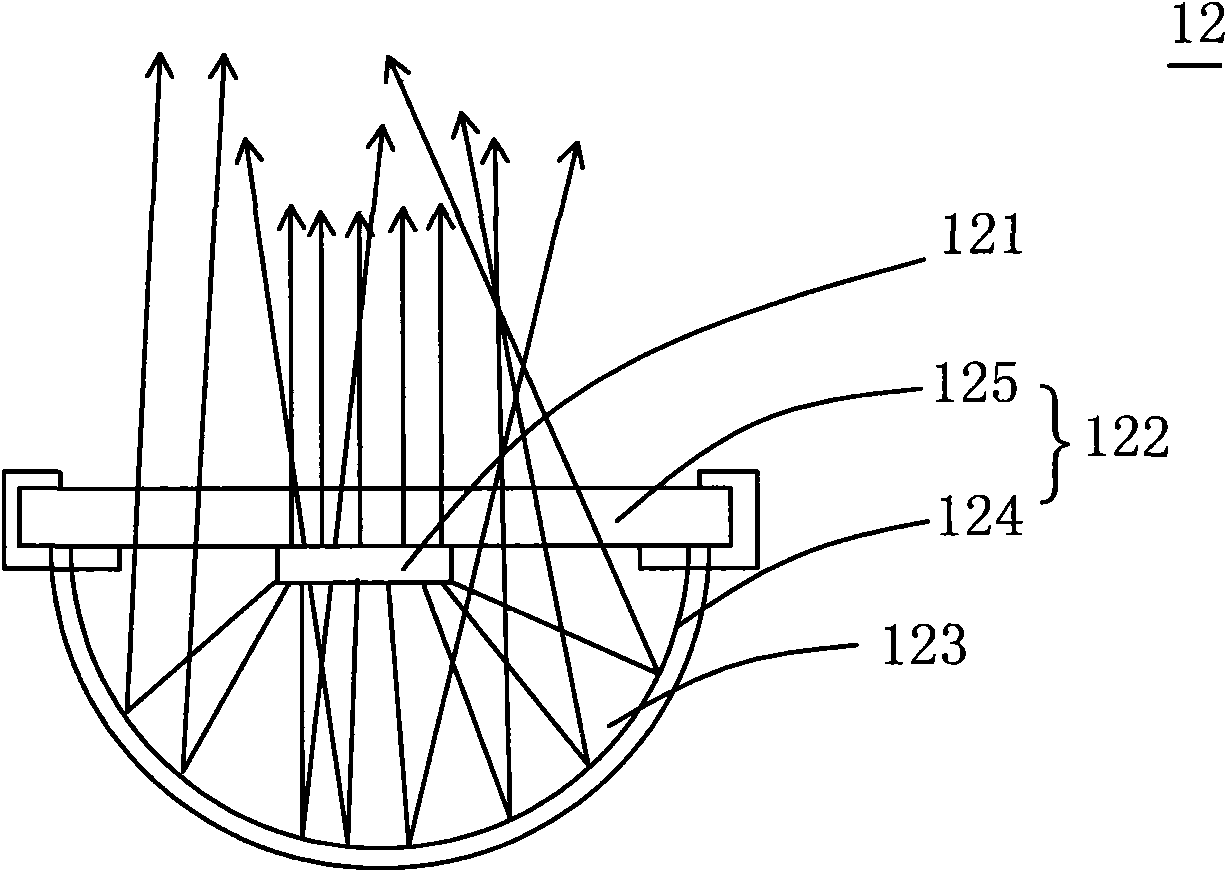

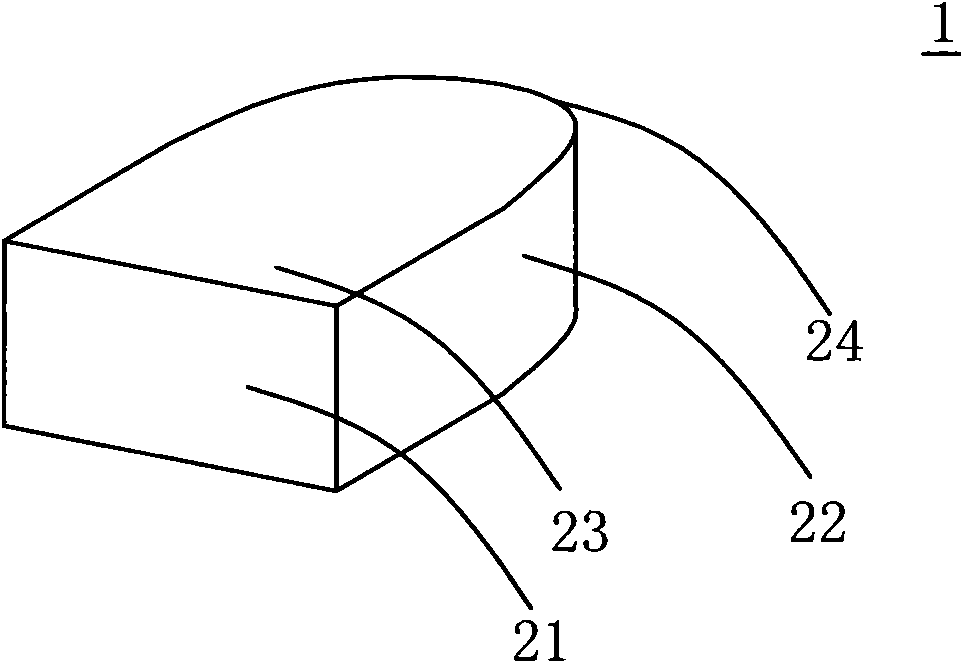

[0019] See image 3 and Figure 4 , image 3 Shown is a schematic perspective view of a light emitting diode according to the present invention, Figure 4 Shown is a schematic cross-sectional view of a light emitting diode according to the present invention. The present invention provides a backlight module, which includes a light-emitting diode 1 and an optical film set (not shown in the figure), etc., wherein the light-emitting diode 1 is used as the light source of the backlight module, and the optical film set (such as a light guide plate or a diffuser plate) etc.) are used to make the distribution of light emitted by the light source more uniform. The light emitting diode 1 includes a package body 2 and a light emitting diode chip 3 . The package 2 is composed of a substrate 21 and a U-shaped case 22 . One end 23 of the U-shaped housing 22 is connected to two ends of the substrate 21 to form an accommodating space for encapsulating the LED chip 3 . The other end 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com