Re-entrant resonant cavities, filters including such cavities and method of manufacture

一种谐振腔、滤波器的技术,应用在凹腔谐振腔领域,能够解决实现谐振腔精确放置有害等问题,达到便宜制造方法、重量轻、良好频率控制的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

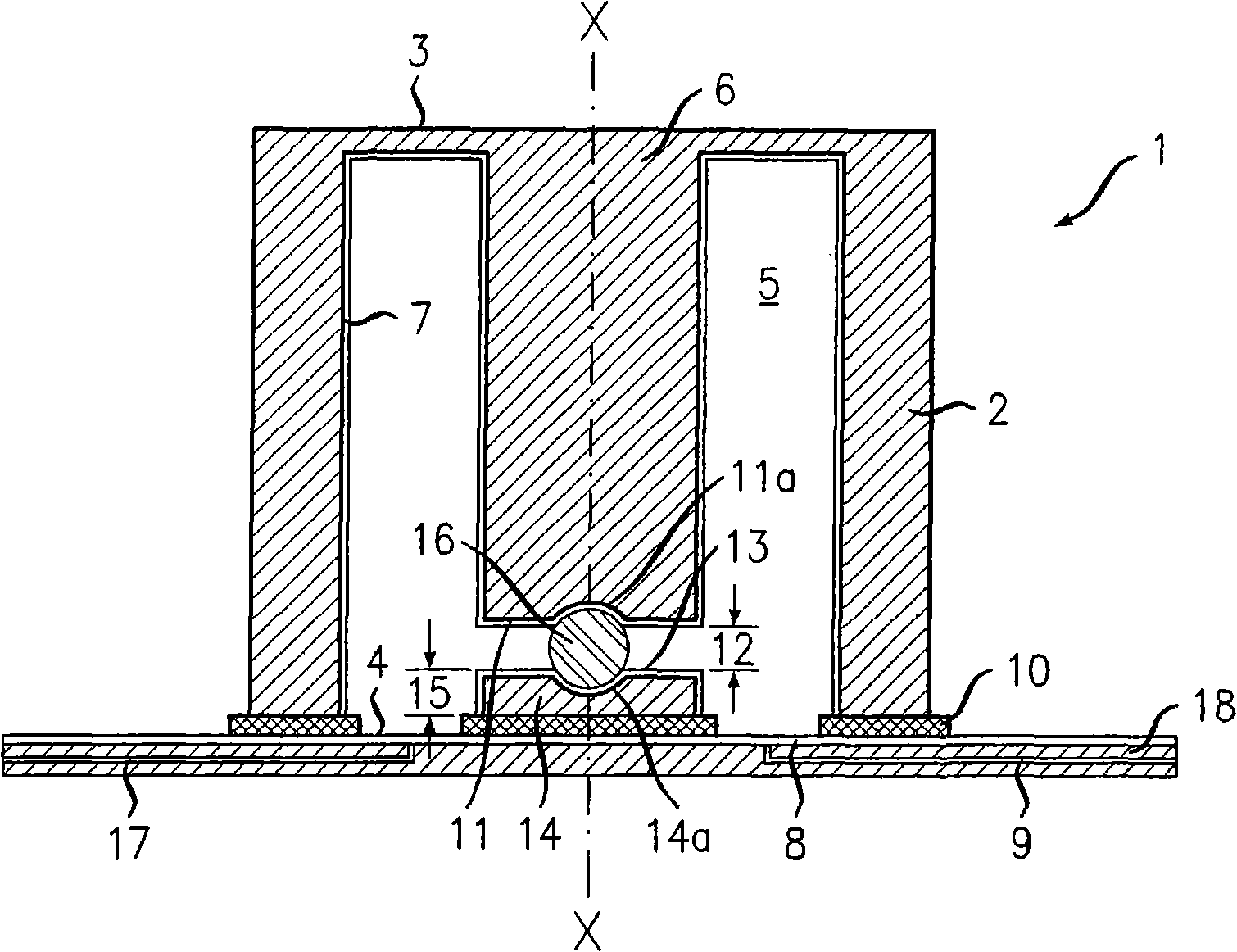

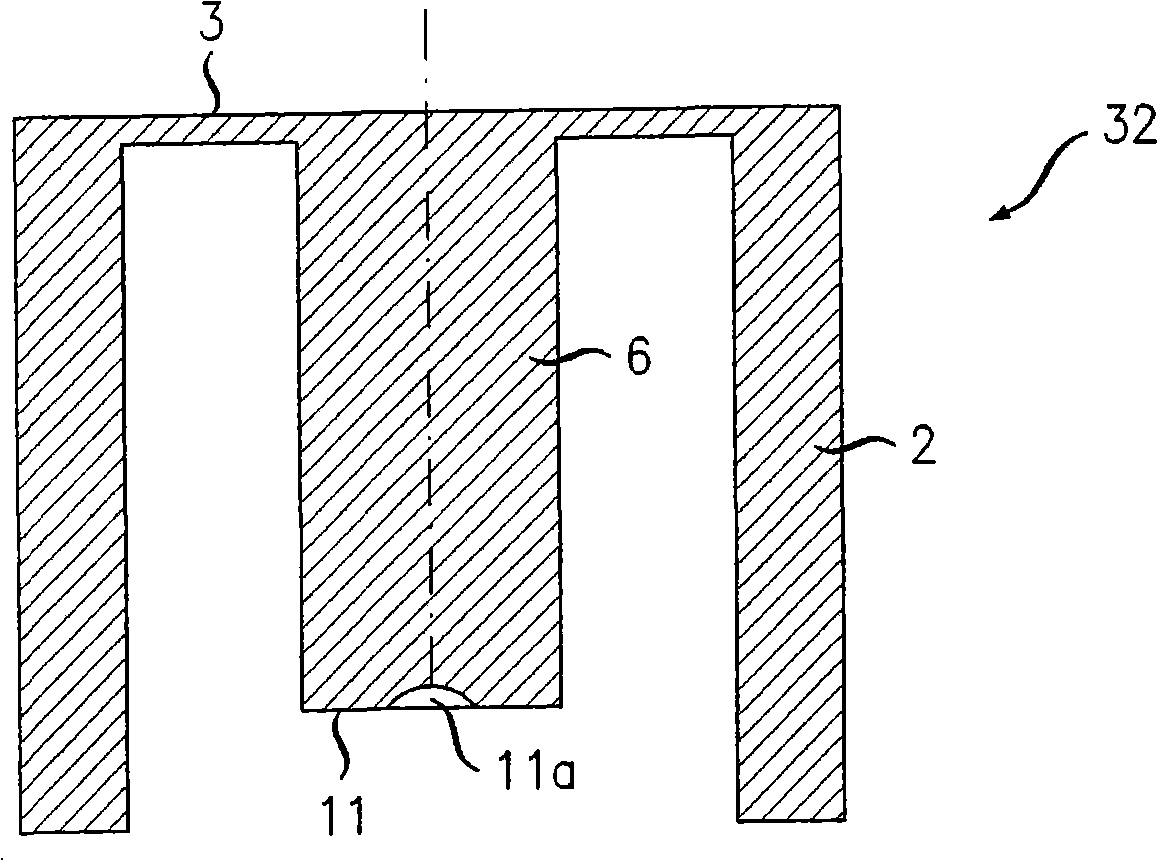

[0031] refer to figure 1 , a concave cavity microwave resonator 1 comprises a cylindrical wall 2 having first and second end walls 3 and 4 at each end to define a generally cylindrical shape therebetween. The volume of 5. Extending from the first end wall 3 into the volume 5 is a stud 6 positioned along the longitudinal axis X-X of the cylindrical wall 2 . The cylindrical wall 2 , the first end wall 3 and the stub 6 are integrally formed as a single molded plastic part, the inner surface of which is plated with a silver layer 7 . The thickness of the first end wall 3 is relatively thinner than that of the cylindrical wall 2 . The second end wall 4 is defined by a metallization 8 carried by a printed circuit board substrate 9 . The cylindrical wall 2 is bonded to the metallization 8 by the solder 10 laid down during the surface mount soldering process during the manufacturing process of the device.

[0032]The end face 11 of the stub 6 defines a gap 12 between said end face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com