Compressor motor and compressor

A technology for compressors and motors, applied in the field of compressors, can solve the problems of motor torque reduction, cost increase, and increase in winding amount, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the present invention will be described in detail based on the illustrated embodiments.

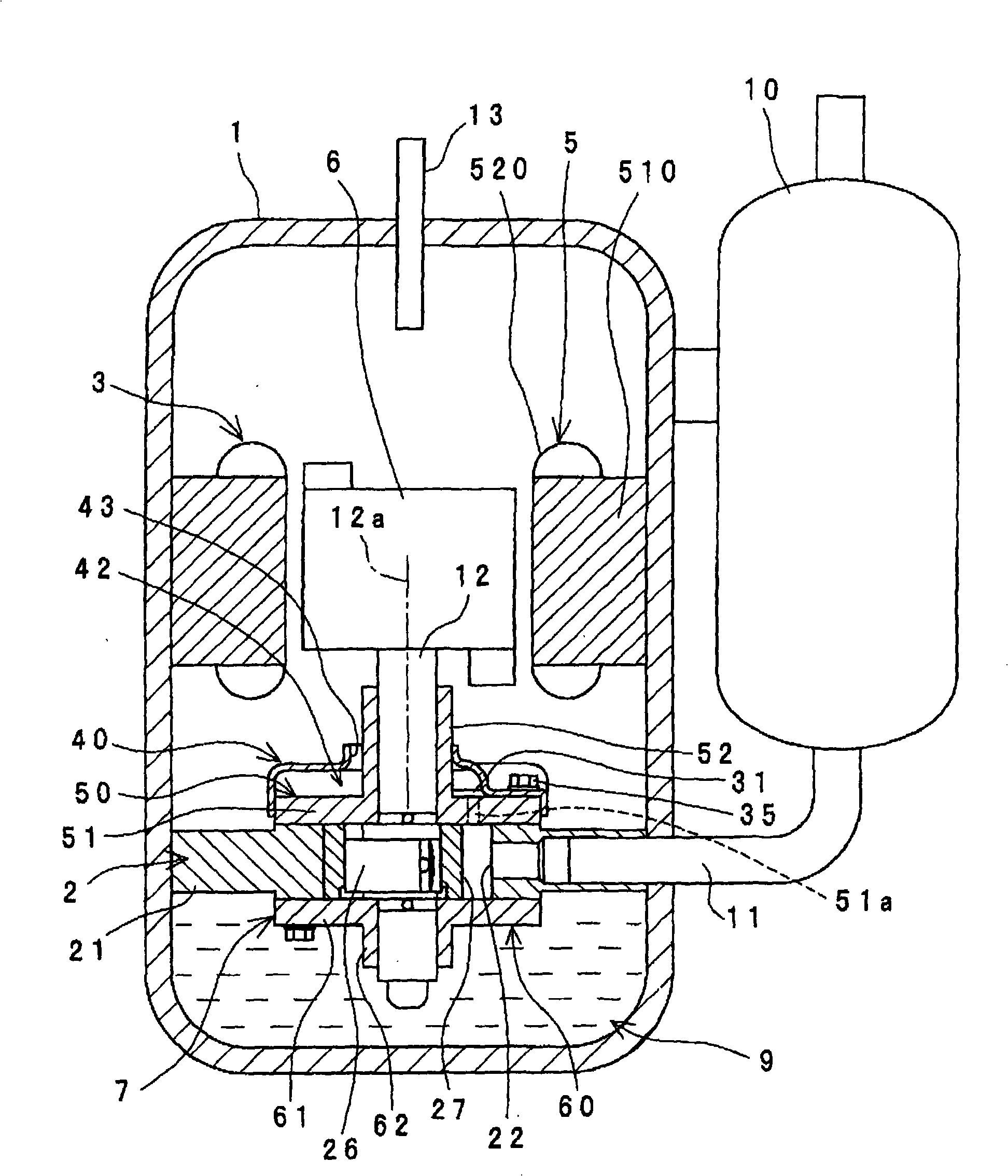

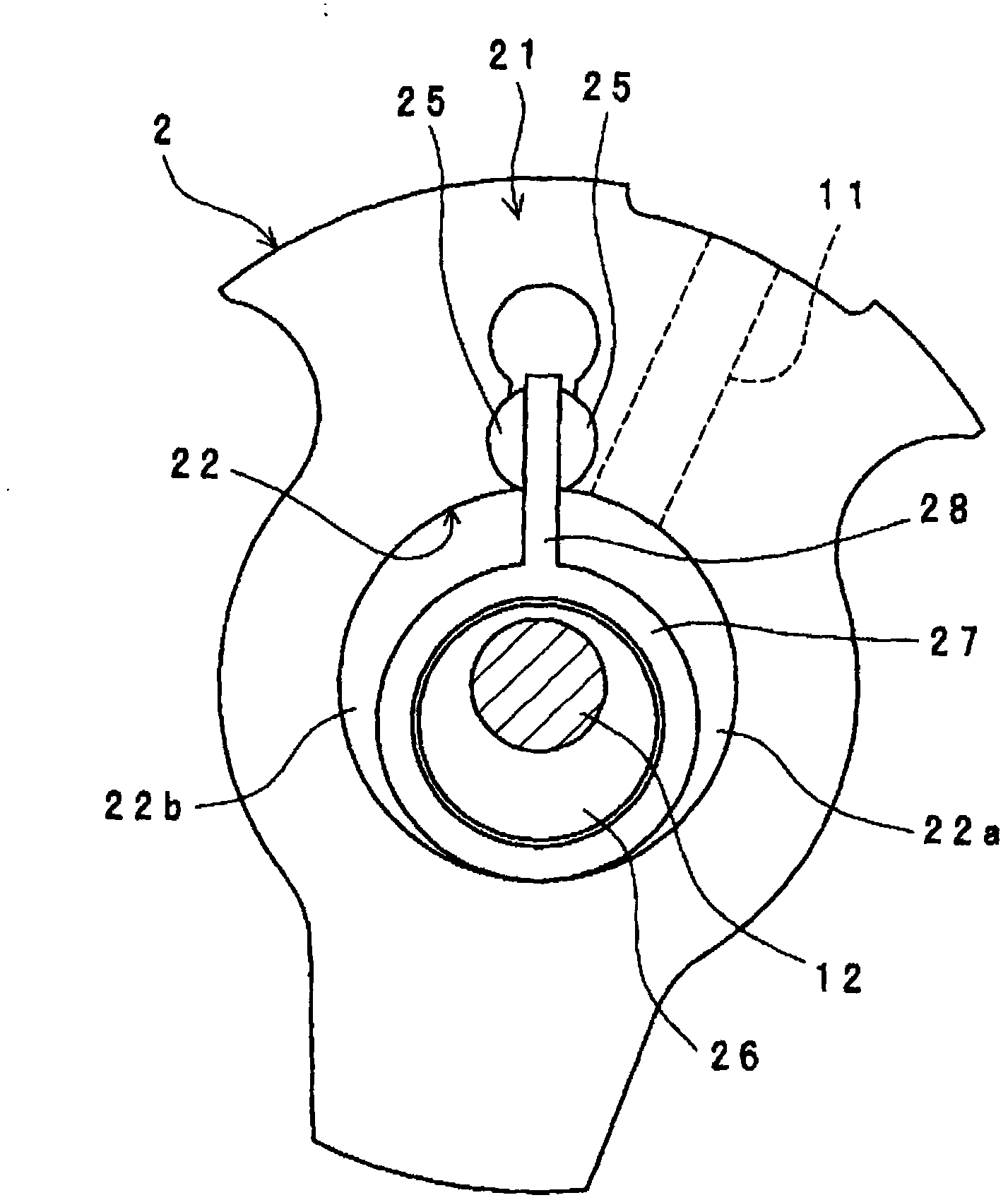

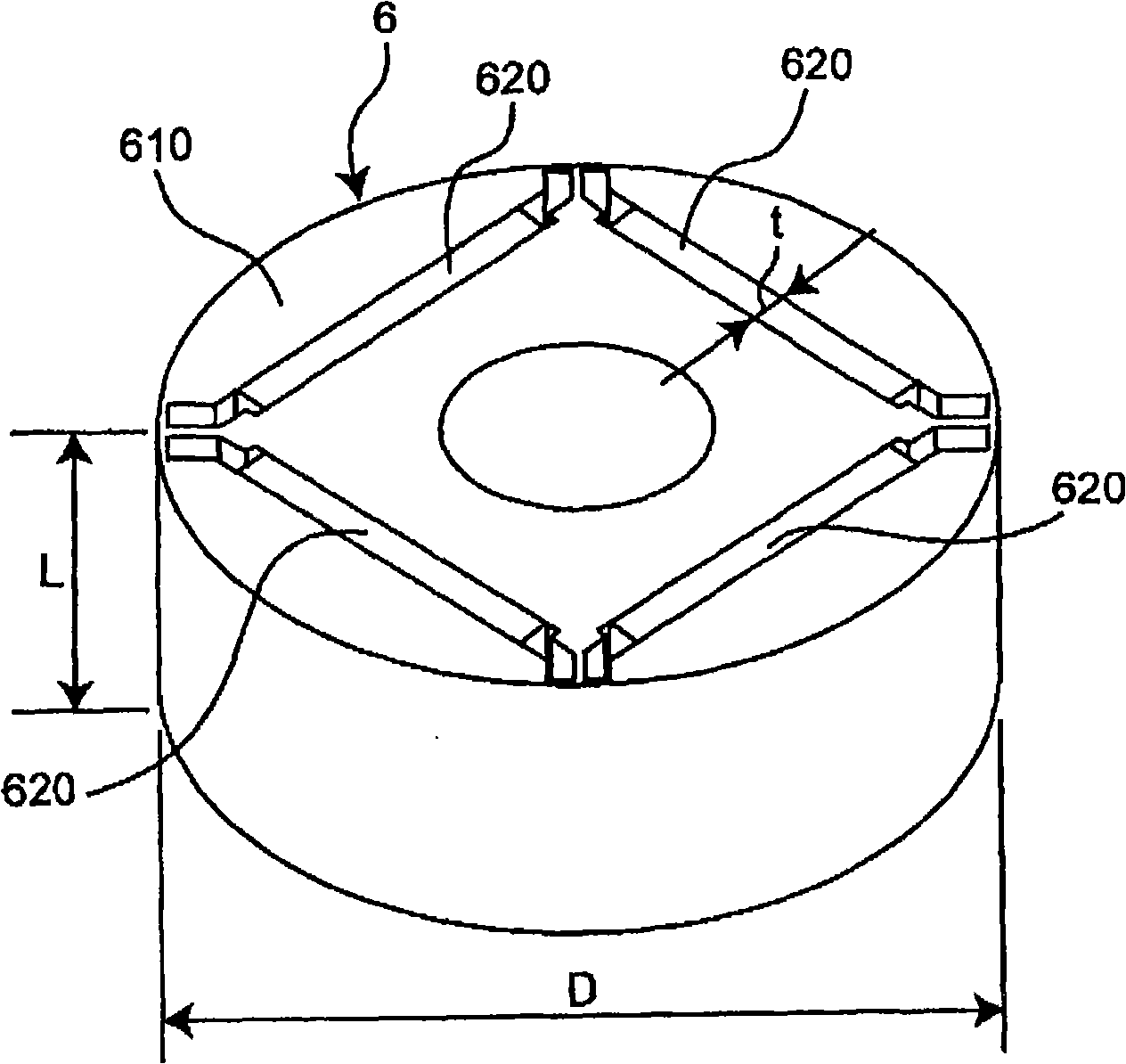

[0031] figure 1 A longitudinal sectional view showing one embodiment of the compressor of the present invention. This compressor includes: an airtight container 1 ; a compression unit 2 arranged in the airtight container 1 ; and a motor 3 arranged in the airtight container 1 and driving the compression unit 2 via a shaft 12 .

[0032] This compressor is a so-called vertical high-pressure dome type rotary compressor, and the compression unit 2 is arranged below and the electric motor 3 is arranged above in the airtight container 1 . The compression unit 2 is driven by the rotor 6 of the electric motor 3 via the shaft 12 .

[0033] The compression unit 2 sucks refrigerant gas from the accumulator 10 through the suction pipe 11 . The refrigerant gas is obtained by controlling an unillustrated condenser, expansion mechanism, and evaporator constituting an air conditione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com