Agglomerated flux for strip submerged arc surfacing

A technology of submerged arc surfacing and sintering flux, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of insufficient effective chemical composition of surfacing layer, high oxidizing property, difficulty in slag removal, etc. Excellent resistance to intergranular corrosion, less carburizing effect of weld metal, and easy slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention can be explained in more detail with reference to the following examples; however, the present invention is not limited to these examples.

[0022] According to the design component content of the present invention, 5 kinds of flux powders were prepared, water glass was used as the binder, and the fluxes were sintered at high temperature as test fluxes, respectively recorded as F1-F5.

[0023] The five kinds of flux components are listed in Table 1 below. They are respectively matched with 309L and 347L steel strips with a width of 60mm and a thickness of 0.5mm for surfacing tests. The test steel plates are 40mm16MnR steel plates;

[0024] Among them, the chemical composition of the steel strip and the base metal is listed in Table 2;

[0025] The surfacing welding process parameters are shown in Table 3;

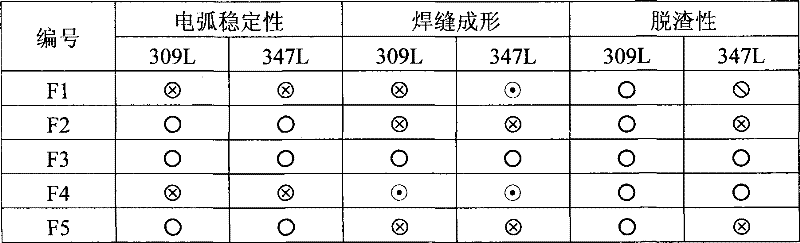

[0026] Among them, the flux surfacing process performance is listed in Table 4;

[0027] In order to carry out the chemical composition analy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com