Precipitation strengthened iron-based high-temperature alloy and preparation method thereof

An iron-based superalloy and precipitation strengthening technology, which is applied in the field of high-temperature metal structural materials, can solve the problems of high cost of nickel-based superalloys, unsuitable material selection for power station boilers, and inability to achieve strengthening effects, and achieves excellent high-temperature lasting strength performance, excellent Long-lasting strength properties, the effect of improving long-lasting properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] By reasonably screening the contents of Ni, Al, and Ti elements and controlling their relative proportions, it is ensured that the alloy can still maintain a high volume fraction of Ni during service 3The presence of Al particles leads to good durable strength properties. The alloy is smelted in a vacuum induction furnace, and the obtained alloy includes: Ni: 36%, Cr: 17%, Mn: 1.0%, Si: 0.5%, C: 0.06%, Mo: 0.8%; W: 0.4% , Ti: 2.1%; Al: 1.4%, and the balance is Fe.

[0033] It adopts vacuum melting and casting molding, and homogenizes at 1170°C for 30 hours, and then conducts thermal deformation at 1050°C. The total deformation amount is not less than 60%, and the final pass deformation amount is higher than 25%. After deformation, solution treatment was carried out at 1100°C for 1 hour and cooled in air, followed by aging at 650°C and 750°C for 8 hours and 4 hours respectively and water cooling.

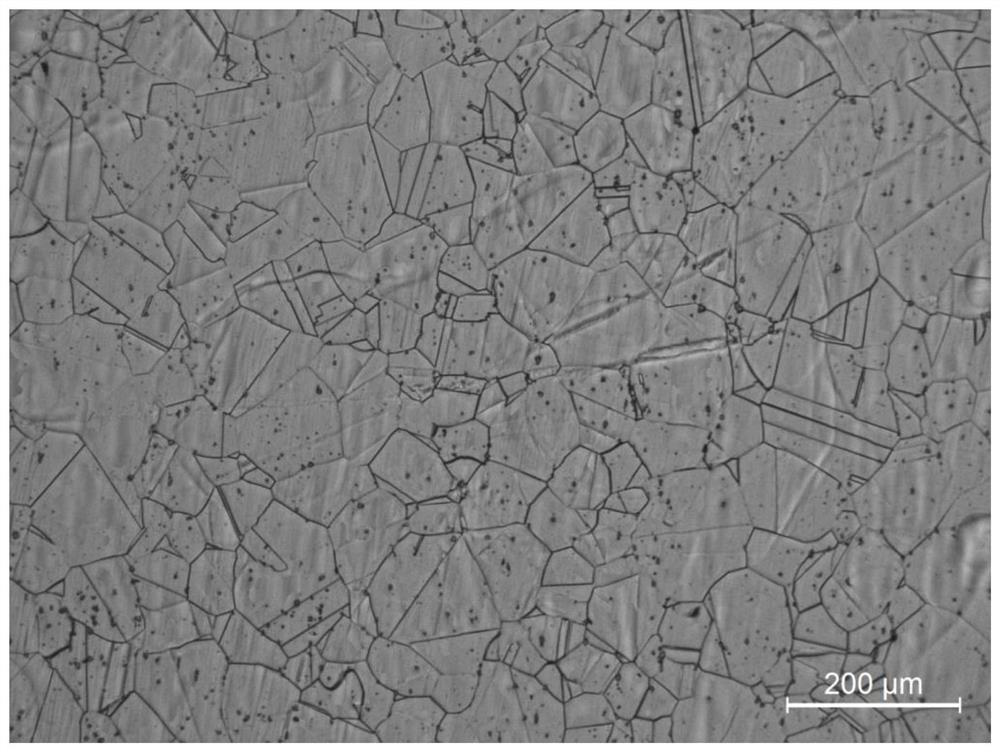

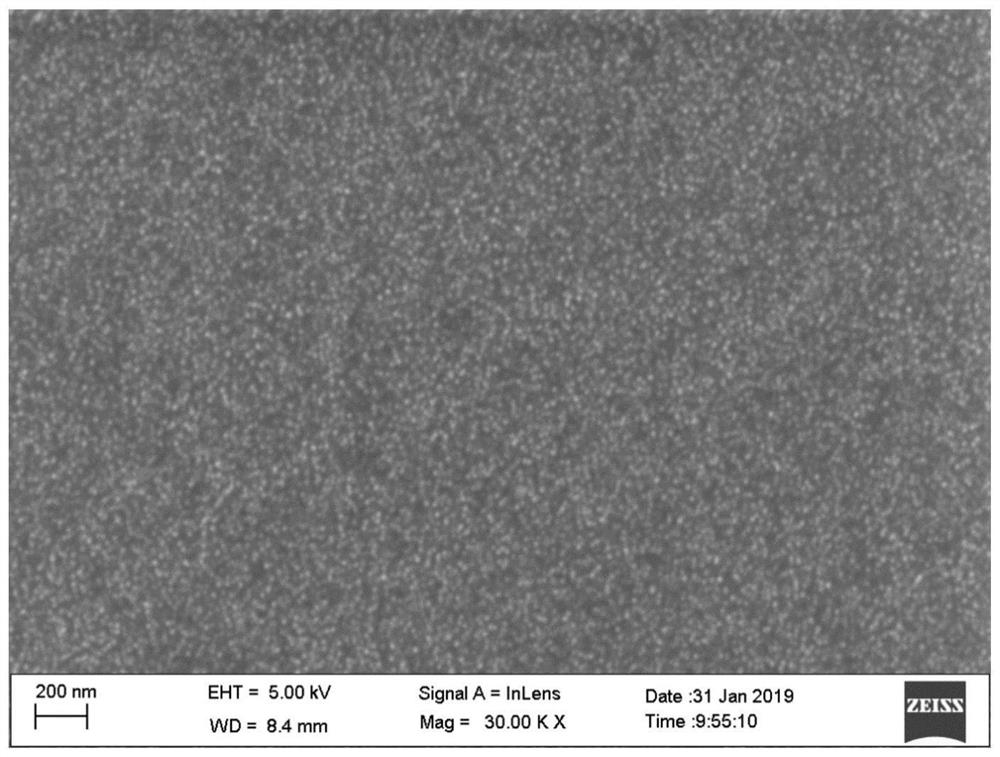

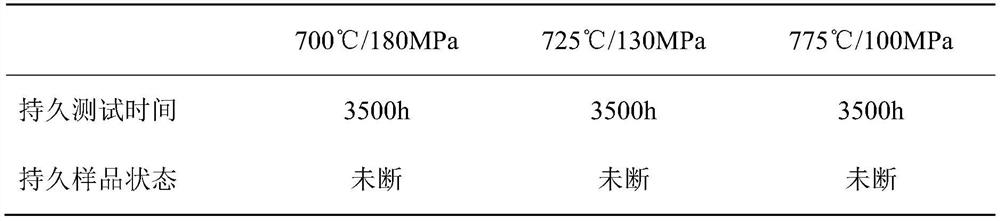

[0034] figure 1 It is the structure morphology of the alloy after heat...

Embodiment 2

[0038] The alloy is smelted in a vacuum induction furnace to obtain the alloy. The alloy includes: Ni: 25%, Cr: 19%, Co: 1%, Si: 0.1%, C: 0.03%, Mo: 0.5%. ; W: 0.5%, Ti: 2.1%; Al: 1.4%, and the balance is Fe.

[0039] It adopts vacuum melting and casting molding, and homogenizes at 1100°C for 50 hours, and then performs thermal deformation at 1020°C. The total deformation amount is not less than 60%, and the final pass deformation amount is higher than 25%. After deformation, solution treatment was carried out at 1080°C for 1 hour and cooled in air, followed by aging at 650°C for 20 hours and water cooled.

Embodiment 3

[0041] The alloy is smelted in a vacuum induction furnace to obtain an alloy, which includes: Ni: 37%, Cr: 18%, Co: 2%, Si: 0.2%, C: 0.1%, Mo: 0.4% ; W: 0.3%, Ti: 2.4%; Al: 1.2%, and the balance is Fe.

[0042] It adopts vacuum melting and casting molding, and homogenizes at 1130°C for 45 hours, and then conducts thermal deformation at 1120°C. The total deformation amount is not less than 60%, and the final pass deformation amount is higher than 25%. After deformation, solution treatment was carried out at 1090°C for 0.8 hours and cooled in air, followed by aging at 800°C for 8 hours and water cooled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com