Fast-disassembly method of aeroplane access cover and bearing lock

A load-bearing lock and cover technology, which is applied in the field of quick release locks, can solve the problems of economic loss, aircraft attendance, composite material cover prying or delamination, and local reinforcement, so as to achieve shortened quick opening and reliable closing time, fast disassembly and assembly, and the effect of large load transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

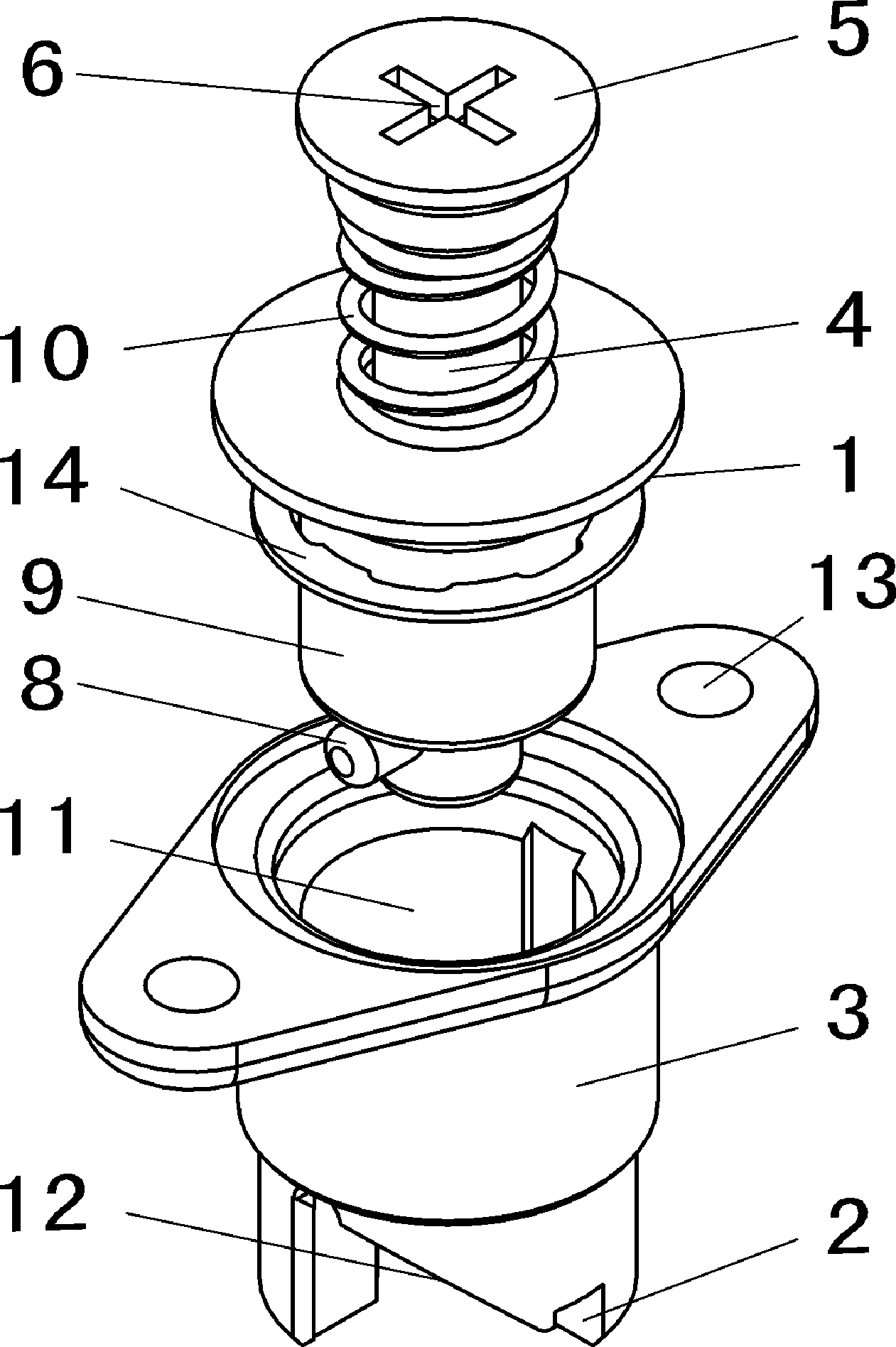

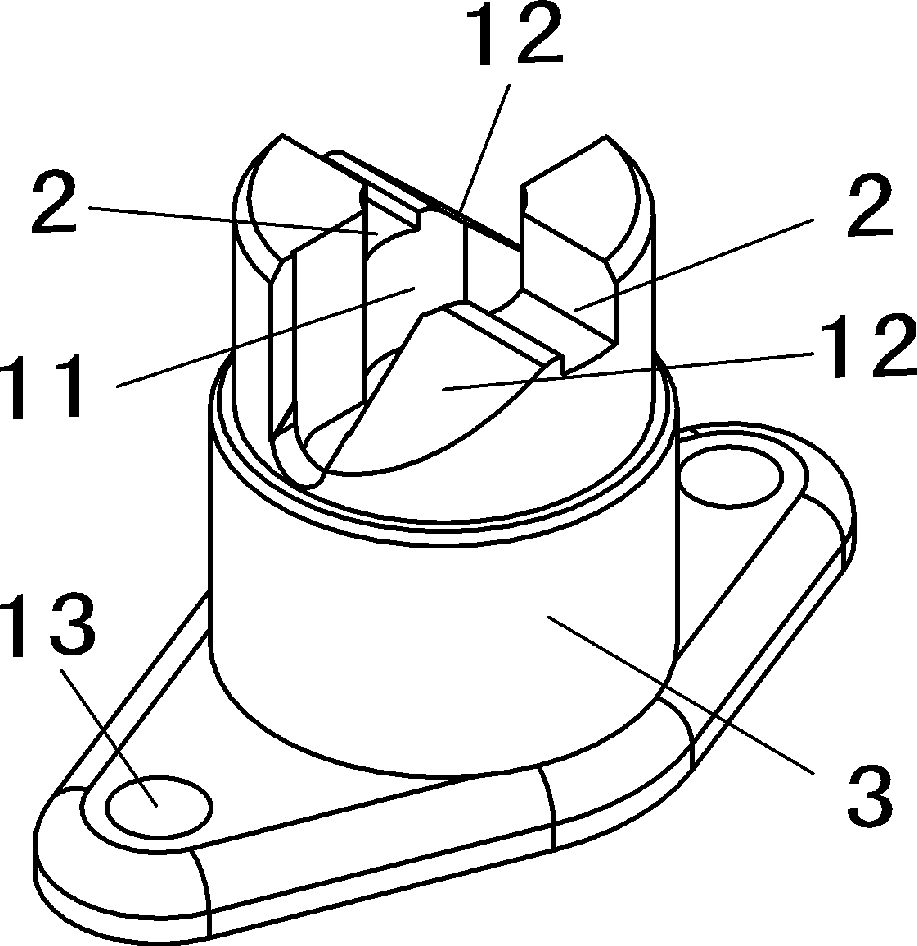

[0022] A quick-release method for the small flap of the aircraft and the load-bearing lock of the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

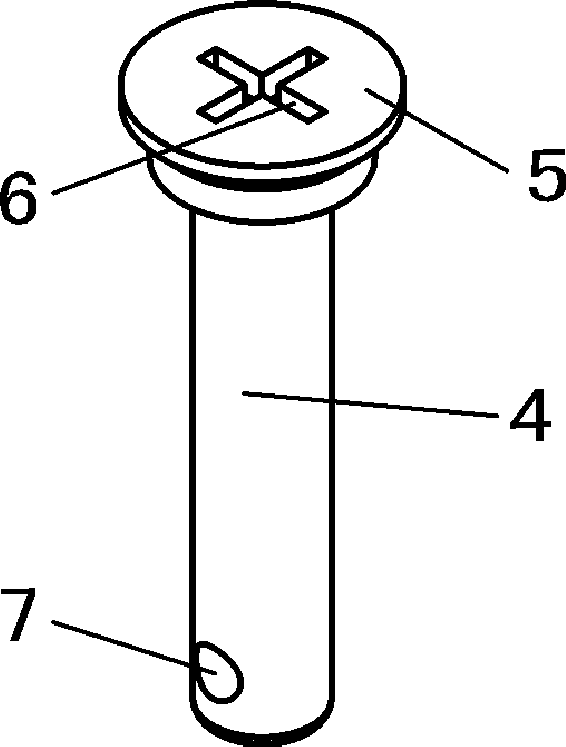

[0023] Example. A quick-release method and quick-release load-bearing lock of an aircraft hatch of the present invention, as figure 1 shown. The method is that the upper lock body 1 with the pin 8 is installed around the mouth cover of the aircraft, and the lower lock body 3 with the draw-in groove 2 is installed on the fuselage frame. The normal direction of the fuselage surface is the same. When locking, the upper lock body 1 is inserted in the lower lock body 3 , and the pin 8 is stuck in the draw-in groove 2 under the action of the spring 10 . When unlocking, use a screwdriver to rotate the bolt 4 connected to the lock pin 8 by 90°, and the pin 8 will escape from the slot 2 against t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com