Variable geometry turbine and turbocharger

A turbine and turbine rotor technology, applied in mechanical equipment, gas turbine devices, machines/engines, etc., can solve problems such as turbine capacity decline and achieve the effect of preventing capacity decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

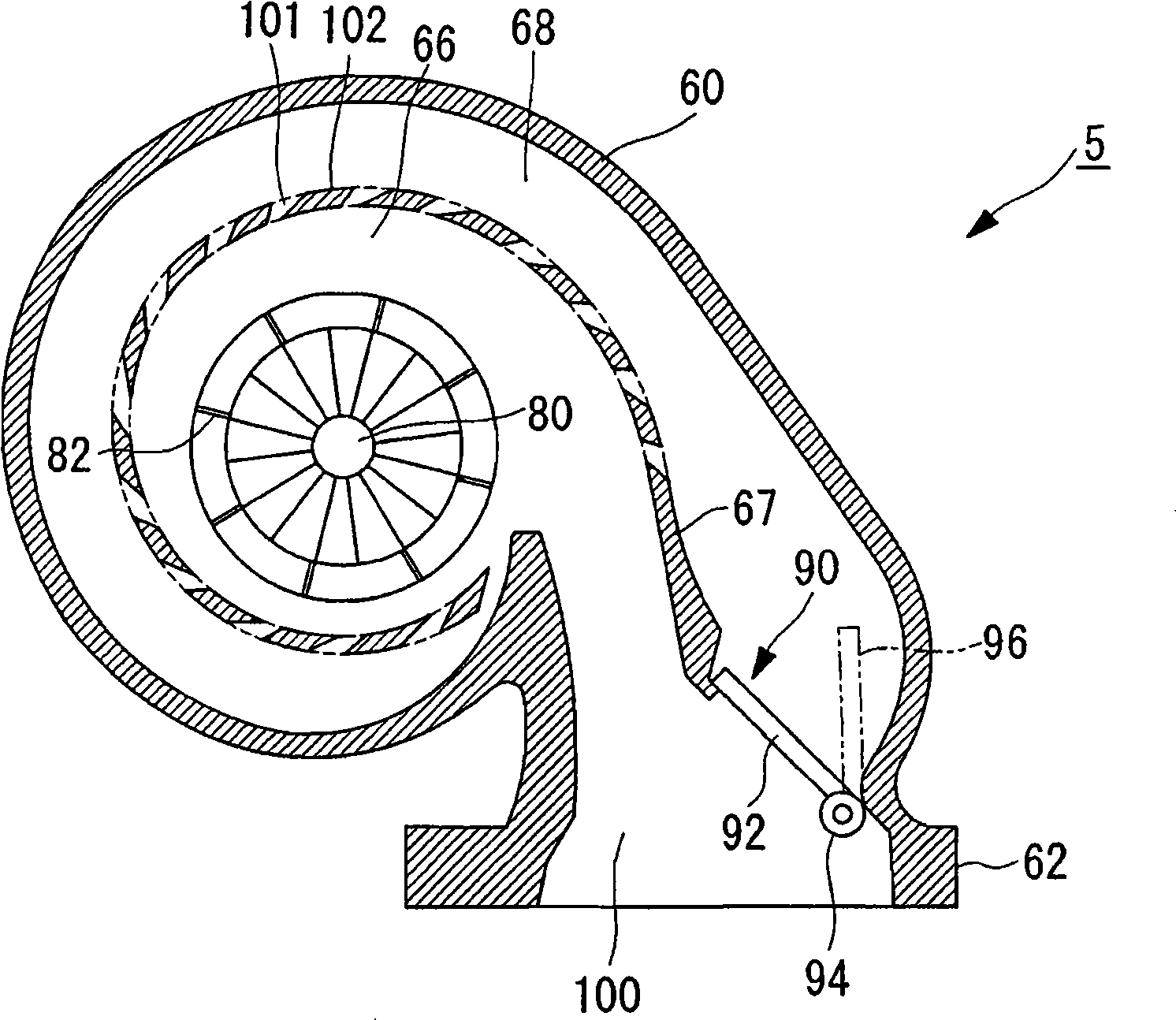

[0053] Next, a first embodiment of a turbine and a turbocharger including the turbine according to the present invention will be described with reference to the drawings.

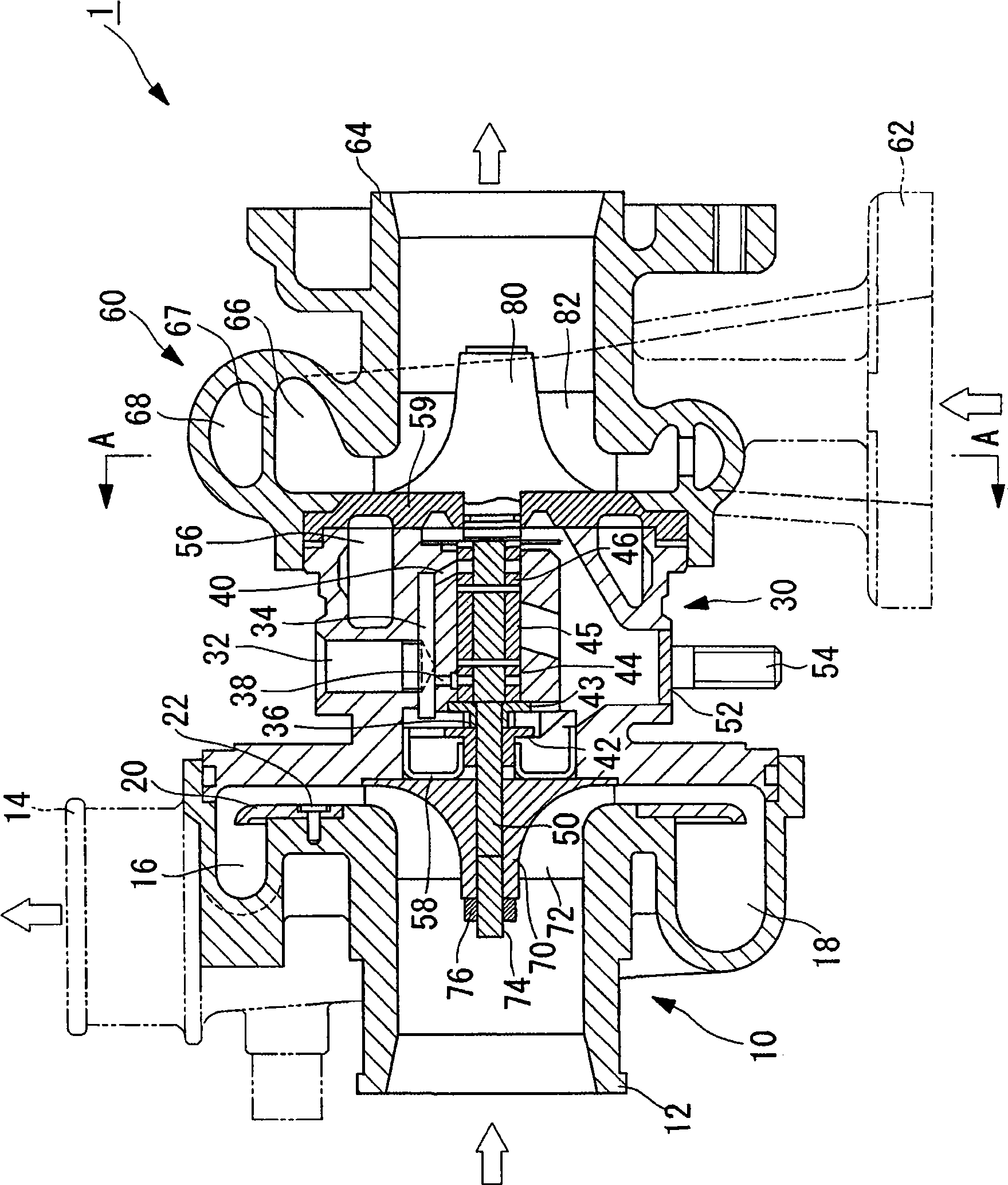

[0054] figure 1 A longitudinal section of the variable capacity turbocharger 1 according to the present embodiment is shown.

[0055] like figure 1 As shown, a compressor housing 10 is provided with a compressor inlet 12 , a compressor outlet 14 , and annular scrolls (scroll) 16 , 18 . The scrolls 16 and 18 extend from a position adjacent to the compressor discharge port 14 toward the outer circumference of the compressor housing 10 and communicate with the compressor discharge port 14 . Furthermore, the cross-sectional area is gradually enlarged as it approaches the compressor discharge port 14 . The supercharger 20 partitions the scroll tubes 16 and 18 and is mounted on the compressor housing 10 through bolts 22 .

[0056] A lubricating oil inlet 32 is formed on the outer periphery of the bearing ...

no. 2 approach

[0069] Next, refer to Figure 8 and Figure 9 , the second embodiment of the present invention will be described.

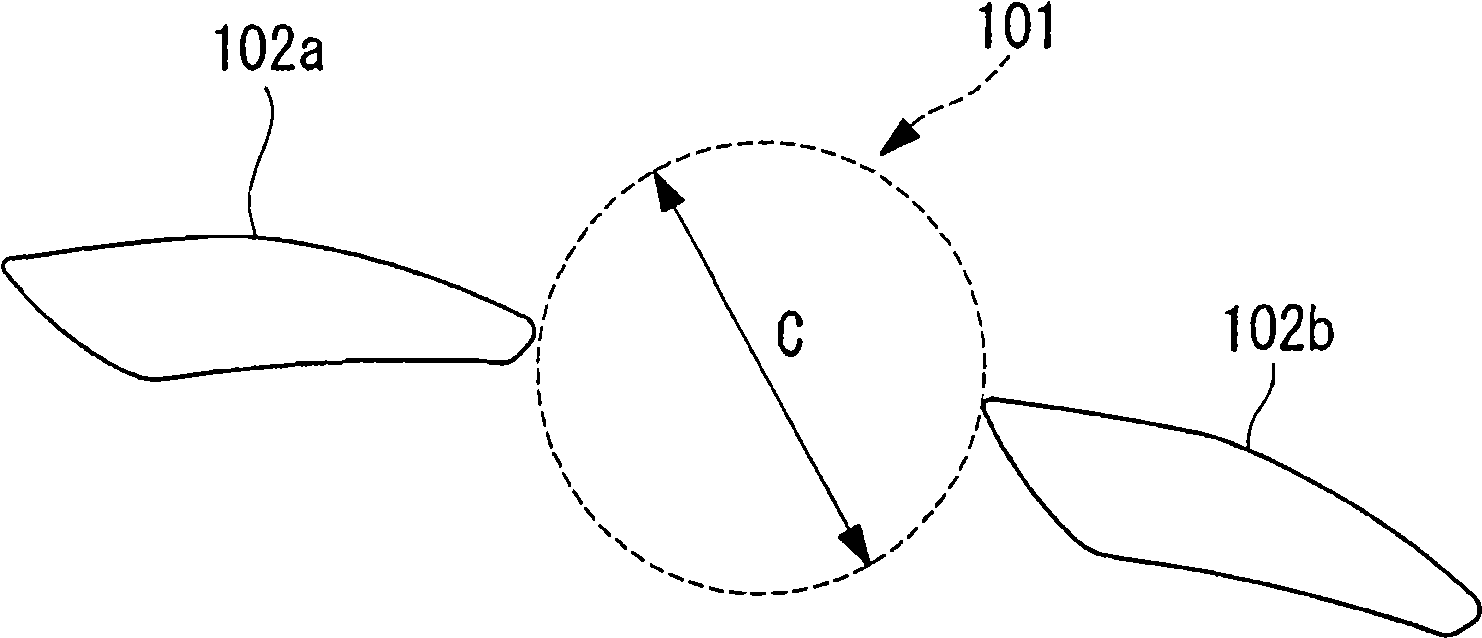

[0070] The difference between the turbine of the present embodiment and the turbocharger equipped with the turbine and the first embodiment is that the flow path area A of the outer scroll portion 68 divided by the flow path area A of the outer scroll portion 68 is changed according to a predetermined rule. The value A / R of the distance R from the center to the center of rotation of the turbine rotor 80 . Hereinafter, the description of the same points of the turbine of the present embodiment and the turbocharger including the same as those of the first embodiment will be omitted, and the differences will be mainly described.

[0071] Figure 8 The relationship between A / R and the swirl angle is shown when the flow path area of the outer scroll portion 68 is A and the distance from the center of the flow path of the outer scroll portion 68 to the rotation ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com