Electro-optical device and method of manufacturing electro-optical device

An electro-optical device and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, circuits, optics, etc., capable of solving problems such as inability to fully reduce display quality, degradation, and inability to adequately block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

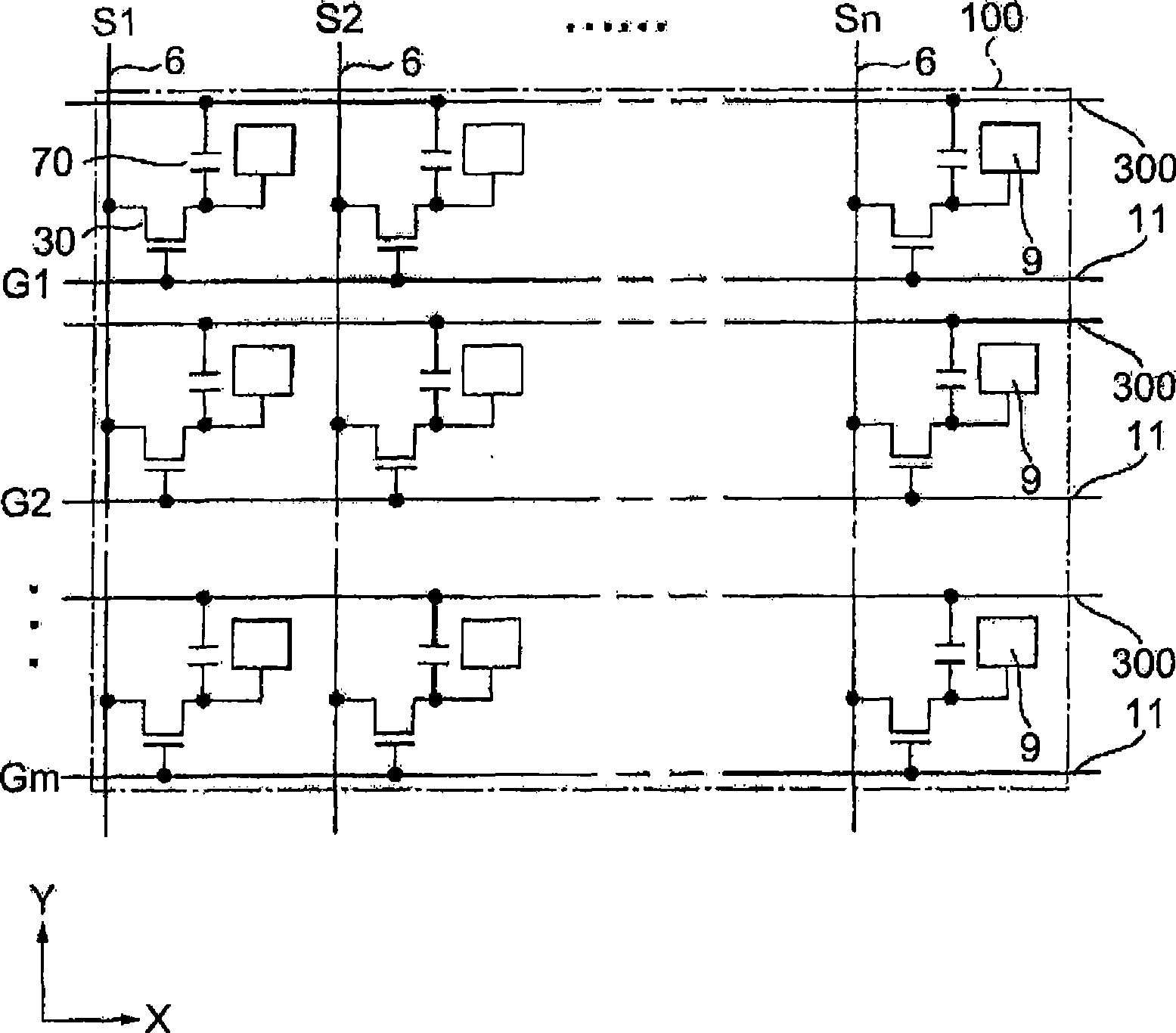

[0034] Hereinafter, as an example of an electro-optical device, a transmissive liquid crystal device of an active matrix driving type with a built-in drive circuit is taken as an example of the embodiments of the present invention, and reference is made to Figure 1 to Figure 6 Be explained. In addition, in each of the drawings shown below, the dimensions and ratios of the respective constituent elements are suitably different from the actual ones in order to make the respective constituent elements recognizable on the drawings.

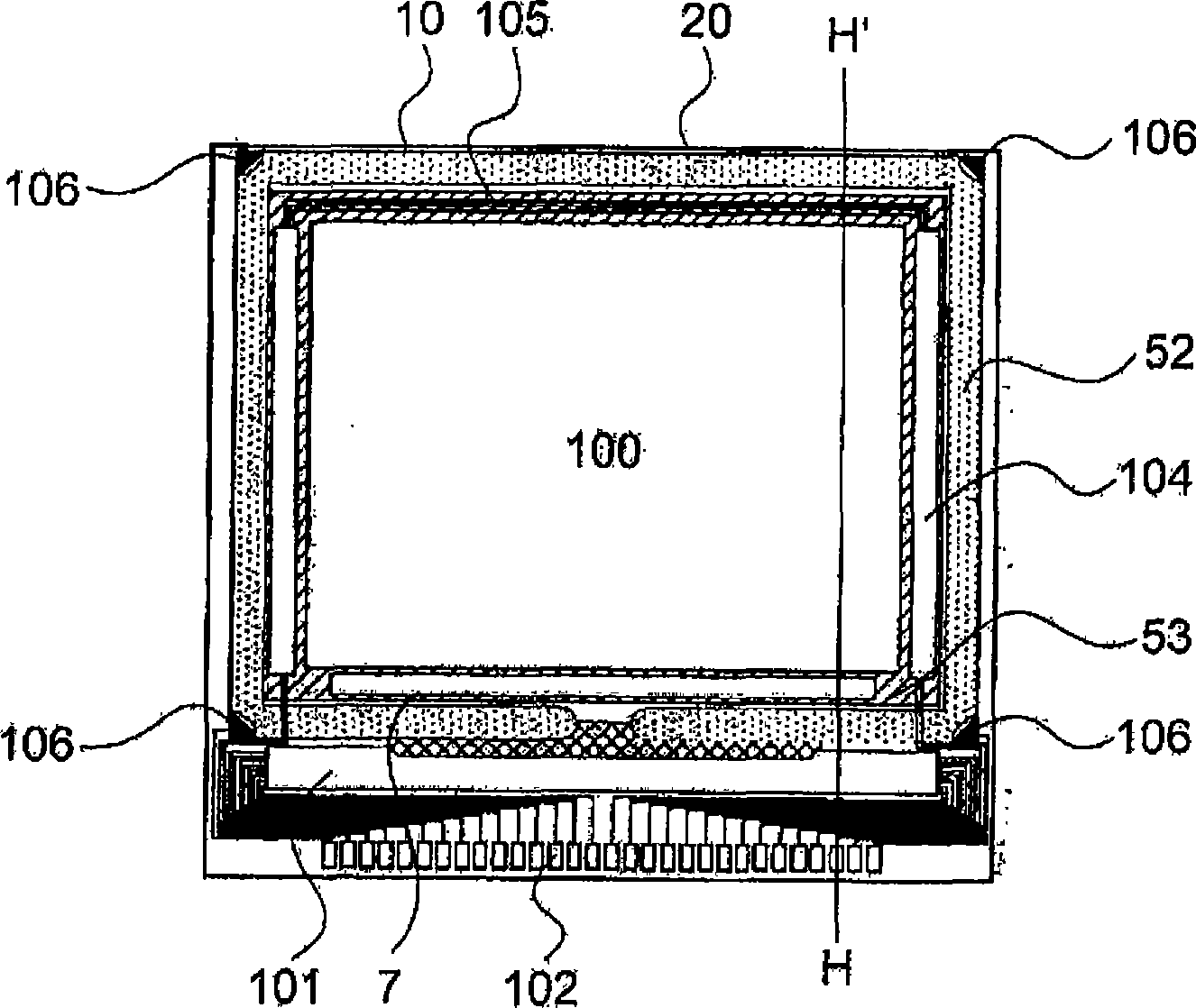

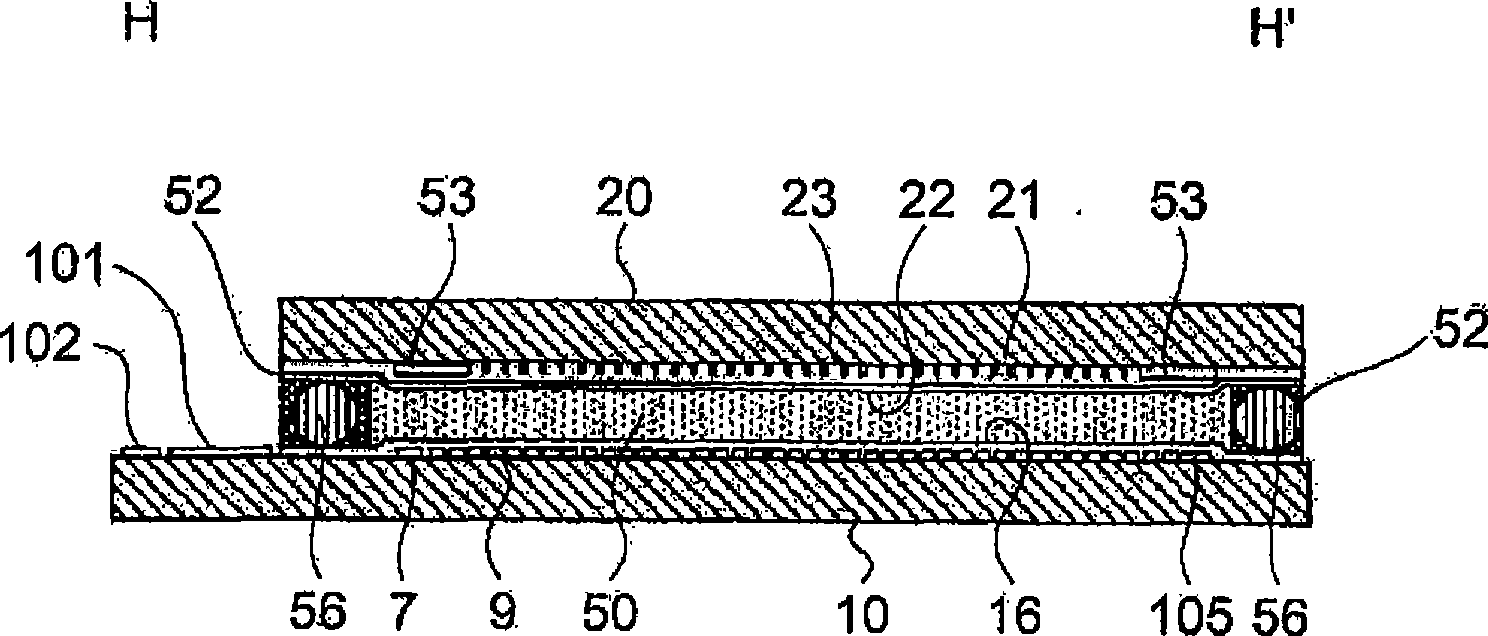

[0035] First, regarding the overall structure of the liquid crystal device in this embodiment mode, refer to figure 1 and figure 2 Be explained. figure 1 It is a schematic plan view of the element substrate 10 and components formed thereon viewed from the counter substrate 20 side of the liquid crystal device, figure 2 ,yes figure 1 A rough cross-sectional view on H-H'.

[0036] exist figure 1 and figure 2 Among them, the liquid crystal devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com