Seal system in particular for joint connections on hot gas flow paths

A sealing system and flow path technology, which is applied in the direction of engine sealing, exhaust device, muffler device, etc., can solve problems such as mechanical weakening, and achieve the effect of simple assembly process and reduced manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

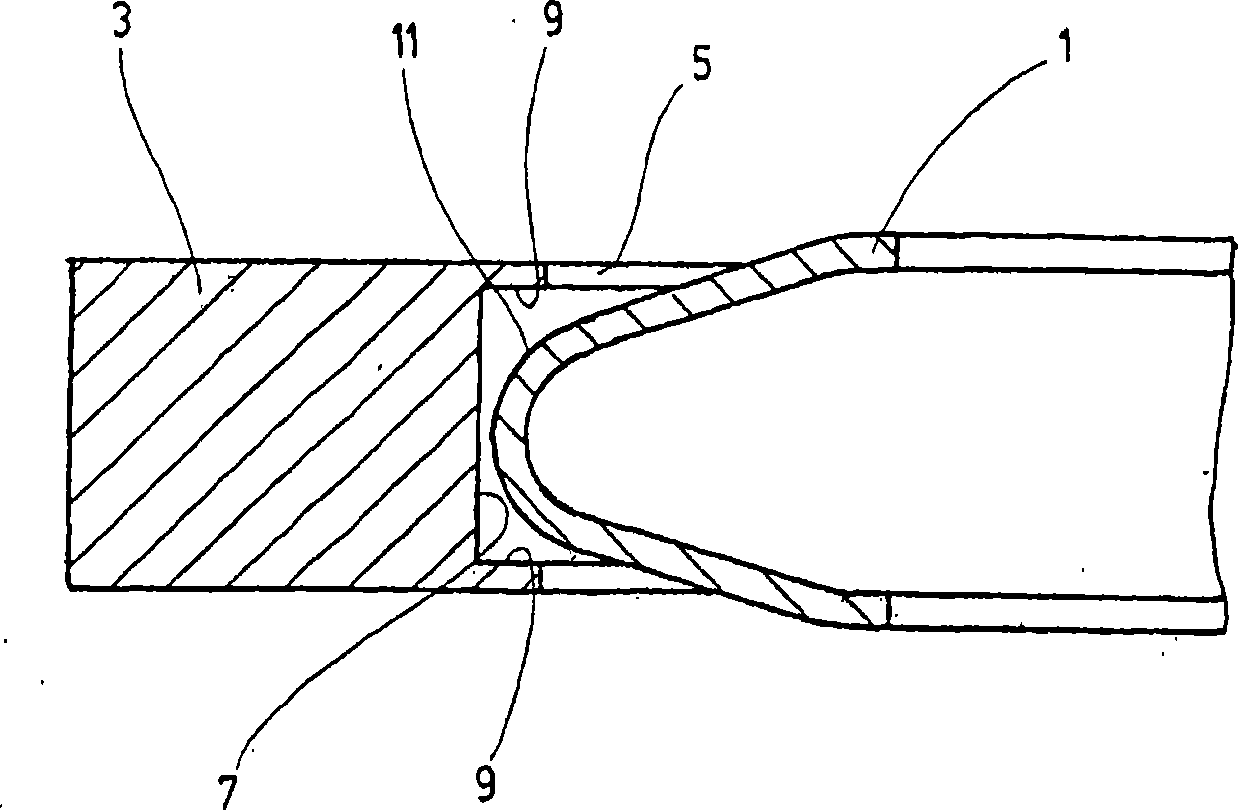

[0025] exist figure 1 The vertically arranged axis extensions shown in 5 to 20 relate to the longitudinal axis of the respective flow path to be sealed.

[0026] figure 1 A first exemplary embodiment of the sealing system is shown, in which only the connection region between the seal seat and the sealing element in the form of a metallic profile ring 1 is shown in a partial longitudinal section shown broken and drawn to an exaggeratedly large scale , which relates to a one-piece shaped body whose profile has a V-shaped cross-sectional shape. The forming ring 1 is arranged in a sealing seat, which has the shape of a circular metal ring body 3, which can be fixed between the not shown connectors of the relevant interface connection device, so that it is in contact with the forming ring. 1 together form a flow path for a hot gas such as an exhaust gas flow. On its radially inner annular edge 5, the annular body 3 has a seat for the forming ring 1, wherein figure 1 In the exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com