Smelt spout enclosure for chemical recovery boilers

A technology of chemical recovery and melting, applied in incinerators, combustion methods, lighting and heating equipment, etc., can solve the problems of capacity overload, inability to be properly washed again, and reduction of reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

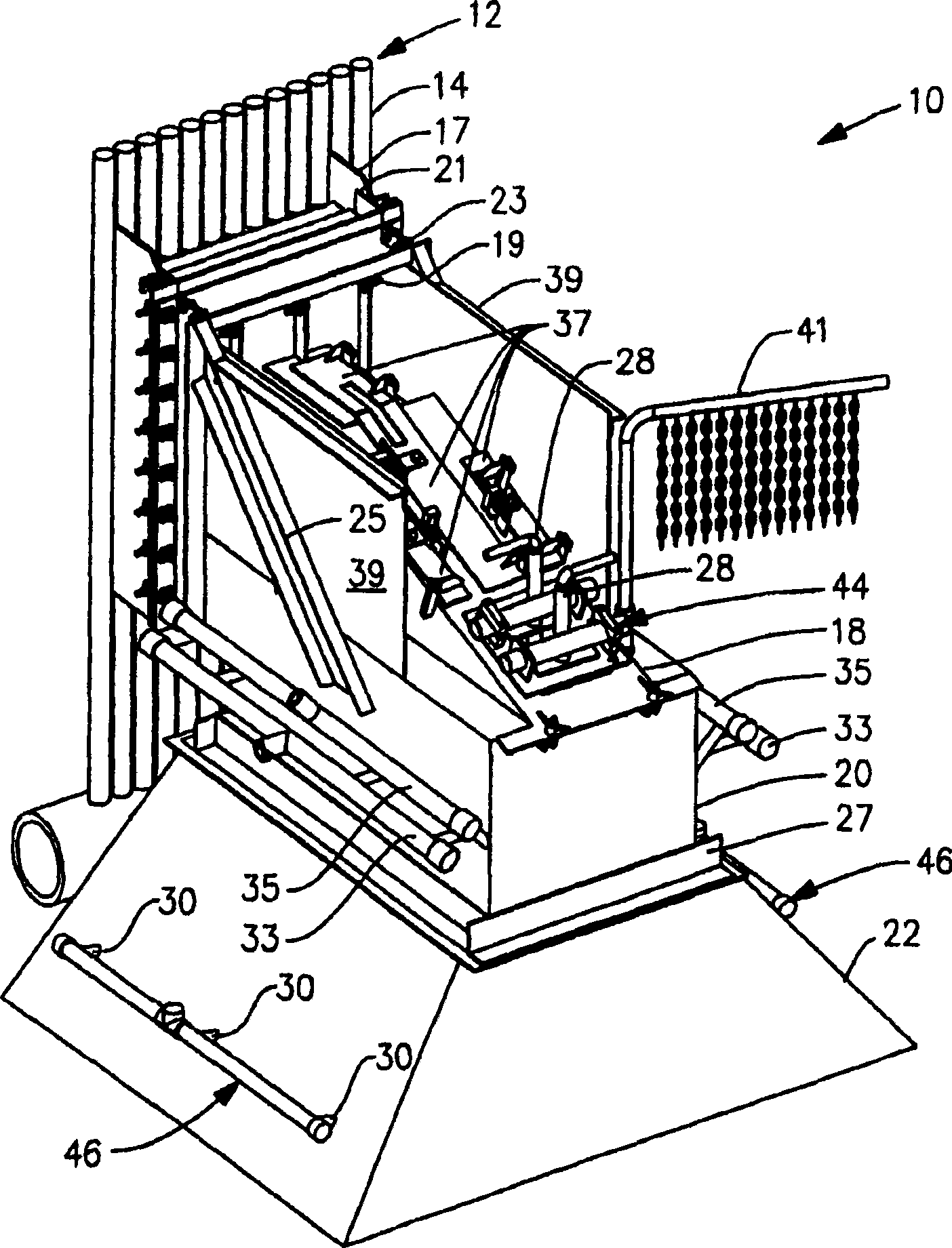

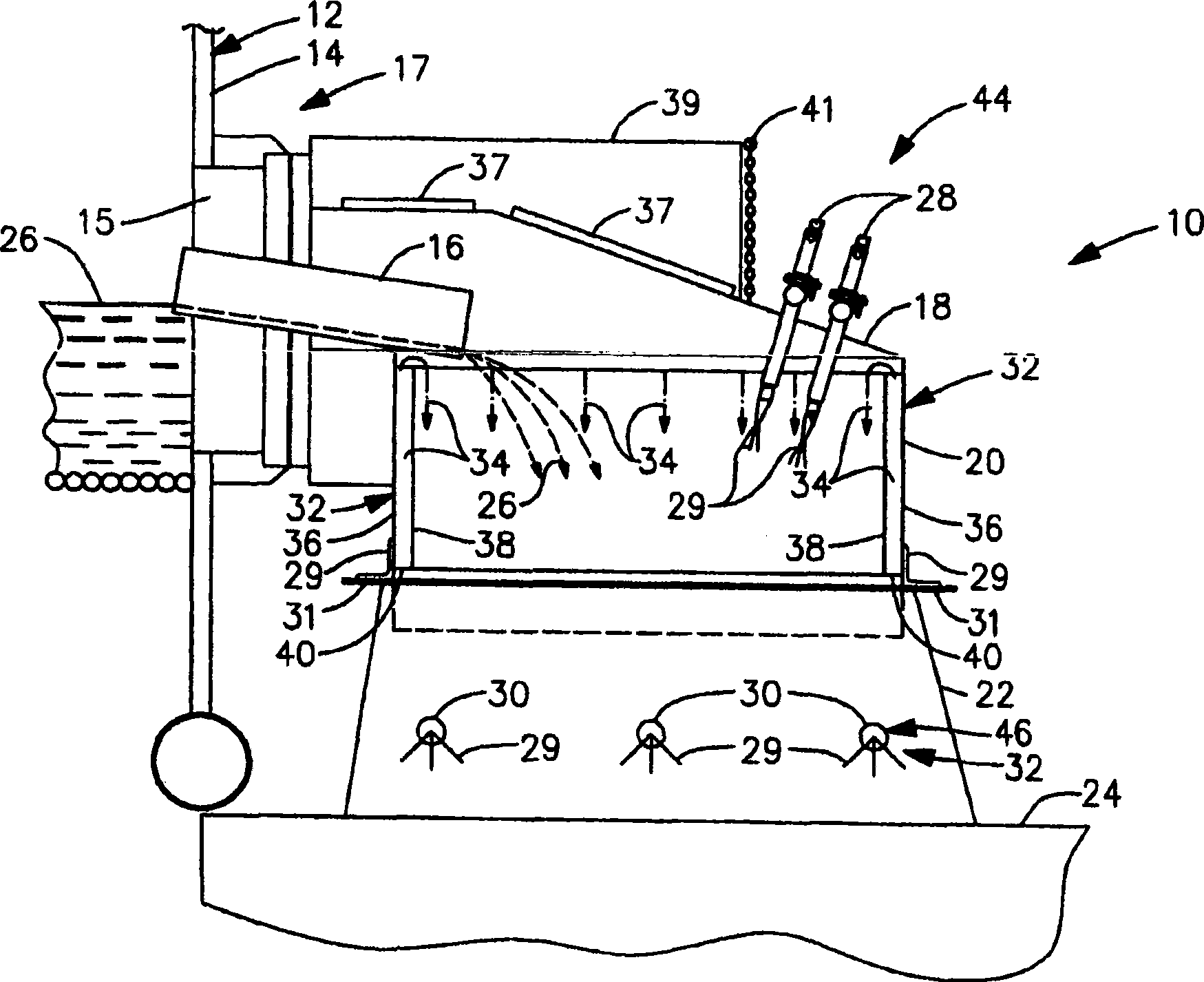

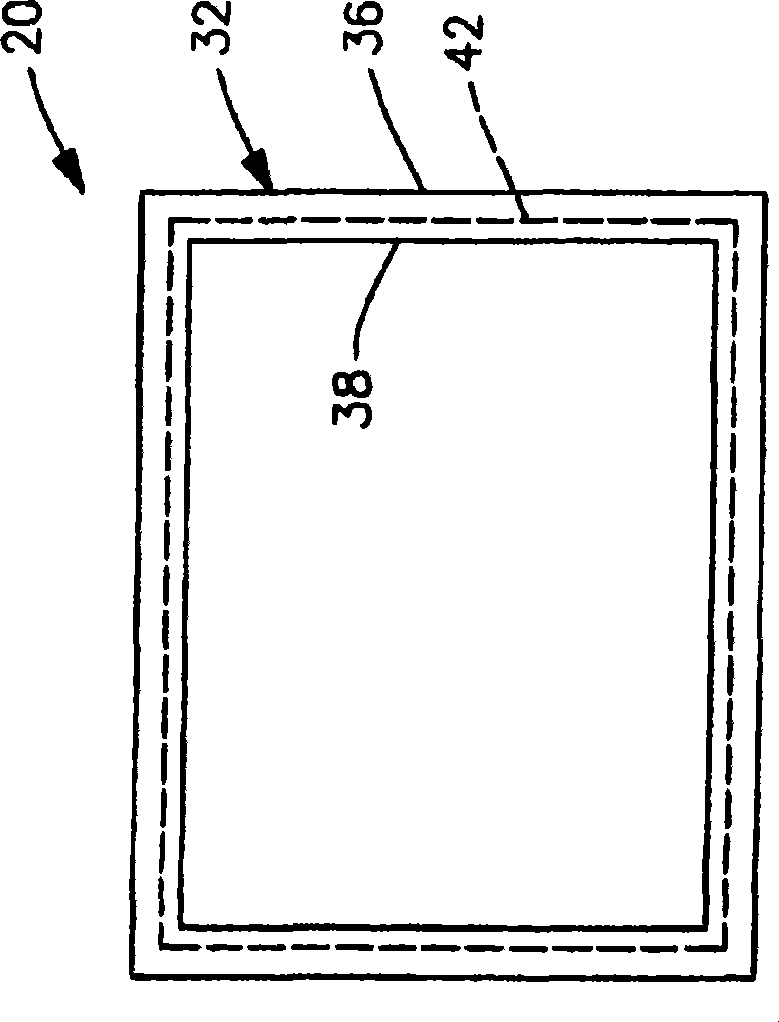

[0021] 【0021】 figure 1 is a perspective view of the smelt chute housing 10 attached to the wall of a conventional chemical recovery boiler 12; and figure 2 is a simplified cross-sectional view of the smelt spout housing 10 . refer to figure 1 and 2 The walls of the recovery boiler 12 are formed by water-cooled tubes 14 shaped to provide openings 15 above the bottom of the furnace section of the boiler 12 . A smelt spout 16 extends through the opening 15 . The portion of the smelt chute 16 which extends outside the boiler 12 is surrounded by an enclosure 10 to prevent splashing of fluid and smelt and discharge of exhaust gases to the surrounding environment. The lower end of the housing 10 is arranged in an opening in the extension 22 of the dissolution tank 24 .

[0022] [0022] Hot, fluid melt 26 flows from the bottom of the furnace portion of boiler 12 through opening 15 to melt chute 16. The melt 26 flows along the bottom of the chute 16 and falls from the free end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com