System for detecting the pressure in a vehicle tyre and/or speed of the vehicle

A vehicle speed, vehicle technology, applied in the direction of measuring fluid pressure, linear/angular velocity measurement, devices using electric/magnetic methods, etc., can solve problems such as inaccuracy and no consideration of tread pattern interference, etc., to increase system costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

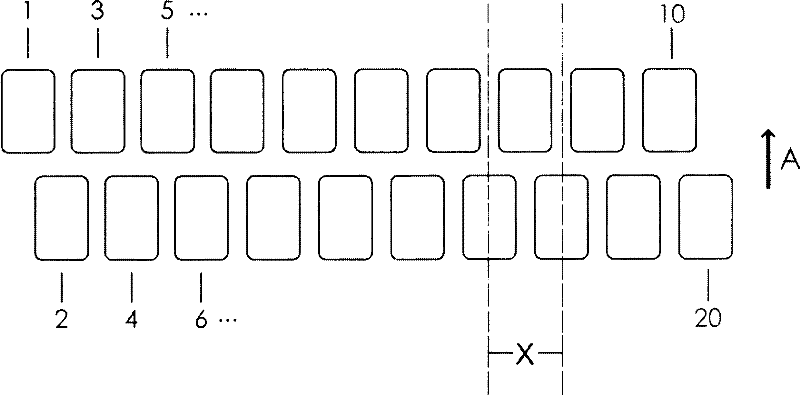

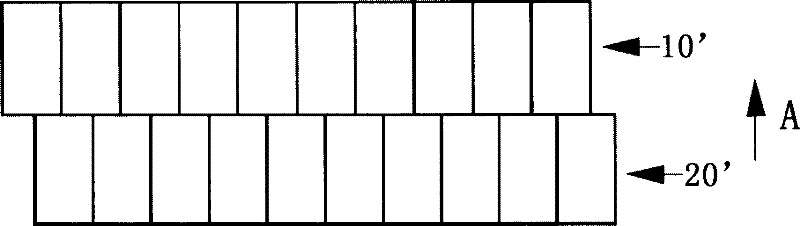

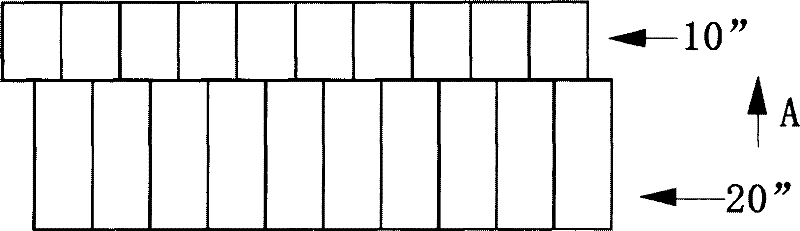

[0035] The forward direction is indicated by arrow A in the figures. A first load sensor row 10, such as the row 10 comprising 1, 3, 5, etc., is offset by an amount x transversely to the direction of travel relative to a second load sensor row 20, such as the row 20 comprising 2, 4, 6, etc. The time difference caused by the speed of the vehicle when the tire contacts the two rows 10, 20 can also be used to calculate this speed. The advantage is that the number of sensors required is only that used in the prior art line, and the invention has the advantage of also measuring velocity. The load sensors are therefore not electrically connected in series but in parallel, or they must at least be read in parallel by the computer.

[0036] The sensor surfaces must be placed at some distance from each other so that they do not overlap. A narrow gap is thus left between the sensor surfaces.

[0037] The offset arrangement allows the individual sensor surfaces to be magnified or expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com