A Low Wrinkle Ratio Chemical Fiber Cloth Printing and Dyeing Process

A printing and dyeing process and wrinkle rate technology, applied in chemical instruments and methods, processing of textile materials, processing of textile material carriers, etc. The uniformity of coloring, the reduction of mutual adhesion, and the good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

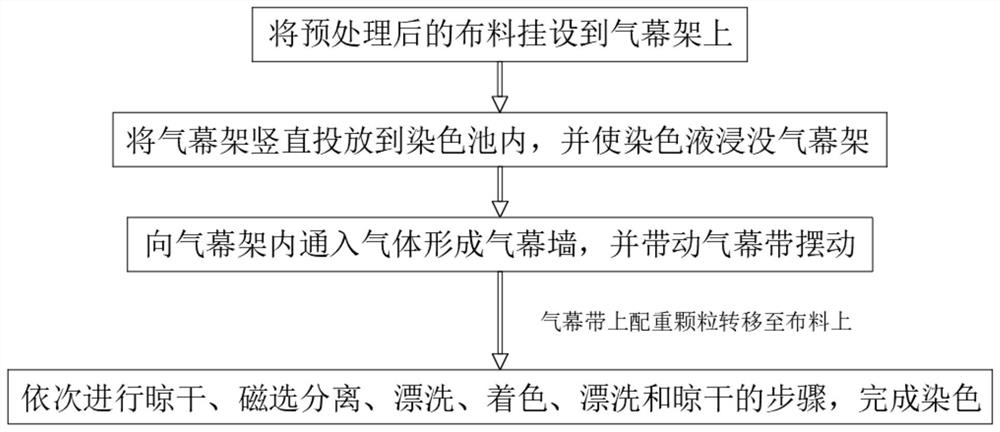

[0049] see figure 1 , a low-wrinkle rate chemical fiber fabric printing and dyeing process, comprising the following steps:

[0050] S1. First, pre-process the fabric to be printed and dyed, including singeing and desizing, and then hang the fabric on the air curtain frame;

[0051] S2. Put the air curtain frame full of fabrics into the dyeing tank vertically, and then pour the dyeing liquid into the dyeing tank until the dyeing liquid submerges the air curtain frame, and the temperature of the dyeing liquid is 80-95 ℃;

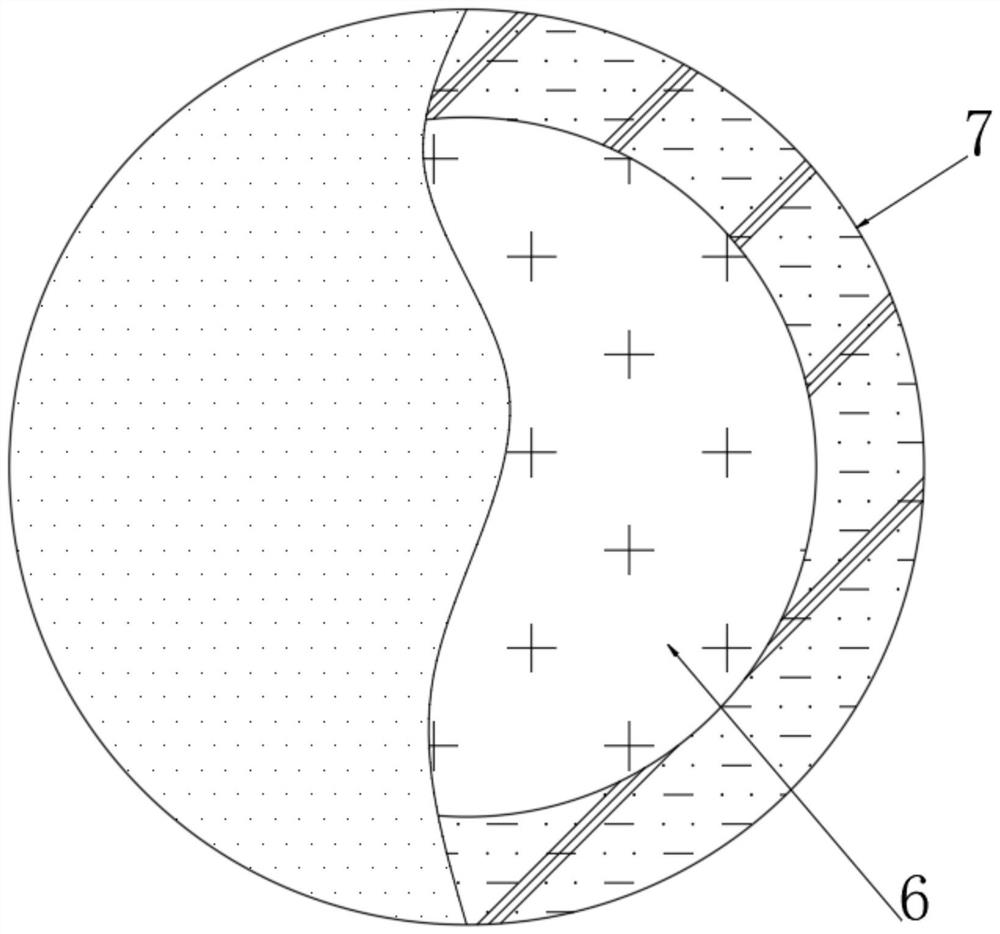

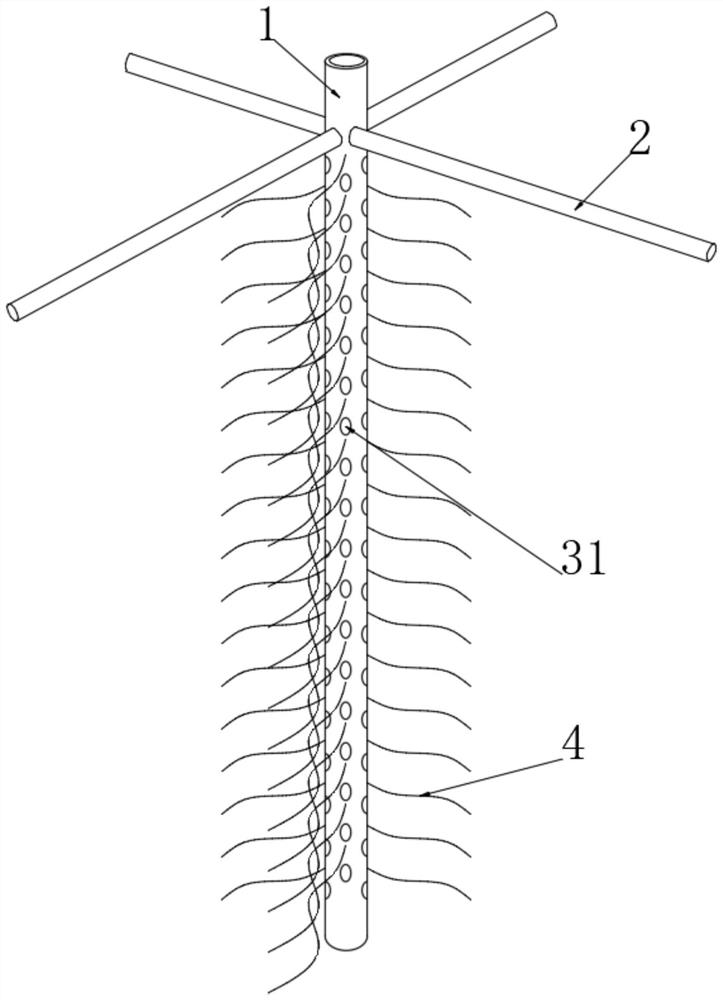

[0052] S3. Introduce inert gas into the air curtain frame to generate an air curtain wall between each adjacent two pieces of cloth, and at the same time drive the air curtain belt 4 to stand up and swing continuously, producing a flapping effect on the cloth on both sides, making the air curtain belt 4 stand up and swing continuously. The weight particles on 4 are gradually transferred to the cloth;

[0053] S4. Continue to inflate for 40-50min, then let s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com