Helical blade rolling mill

A technology of spiral blades and rolling mills, applied in the field of mechanical rolling, which can solve the problems of increasing debugging costs, complex adjustment of blade rolling gaps, and complex adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

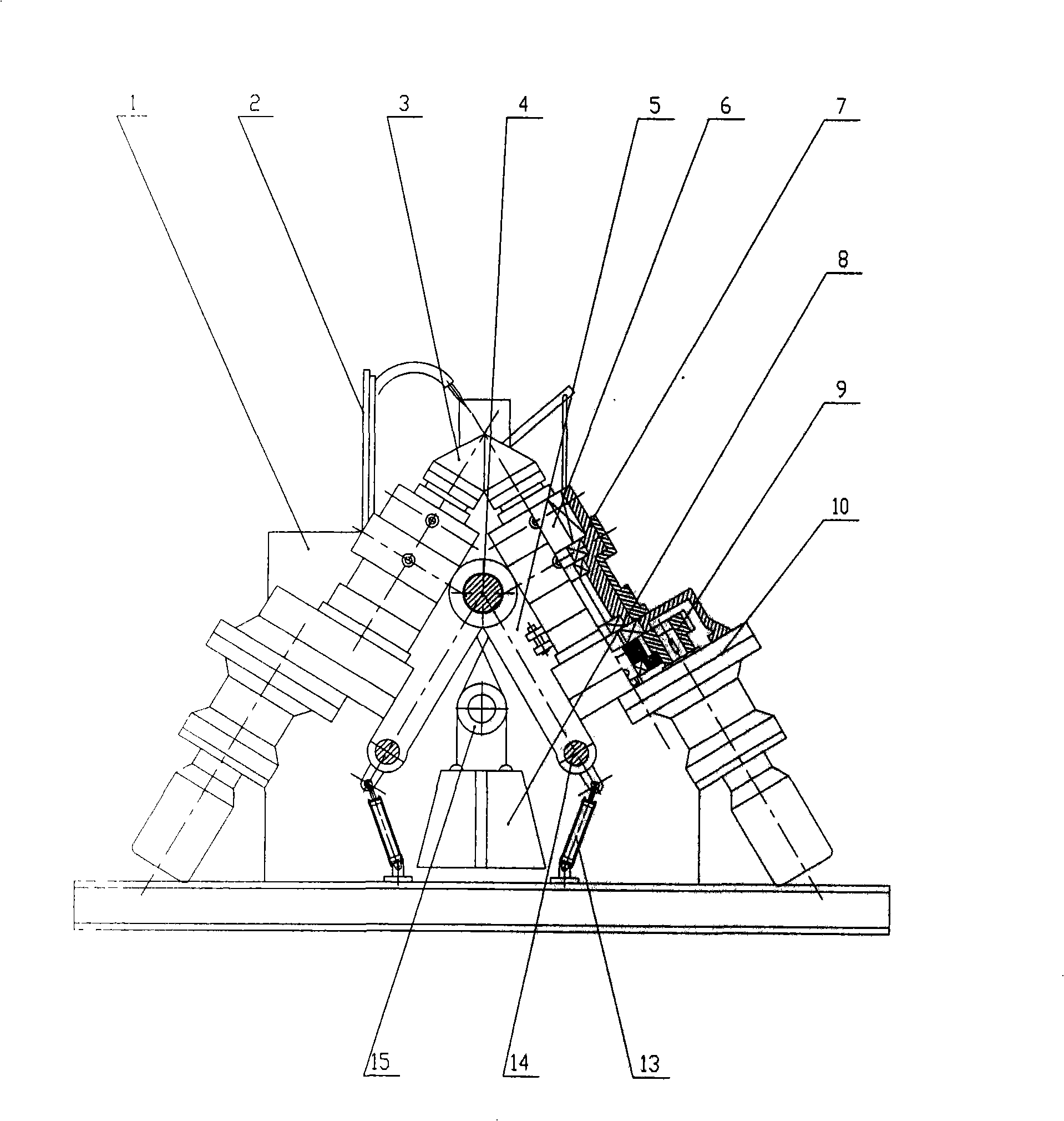

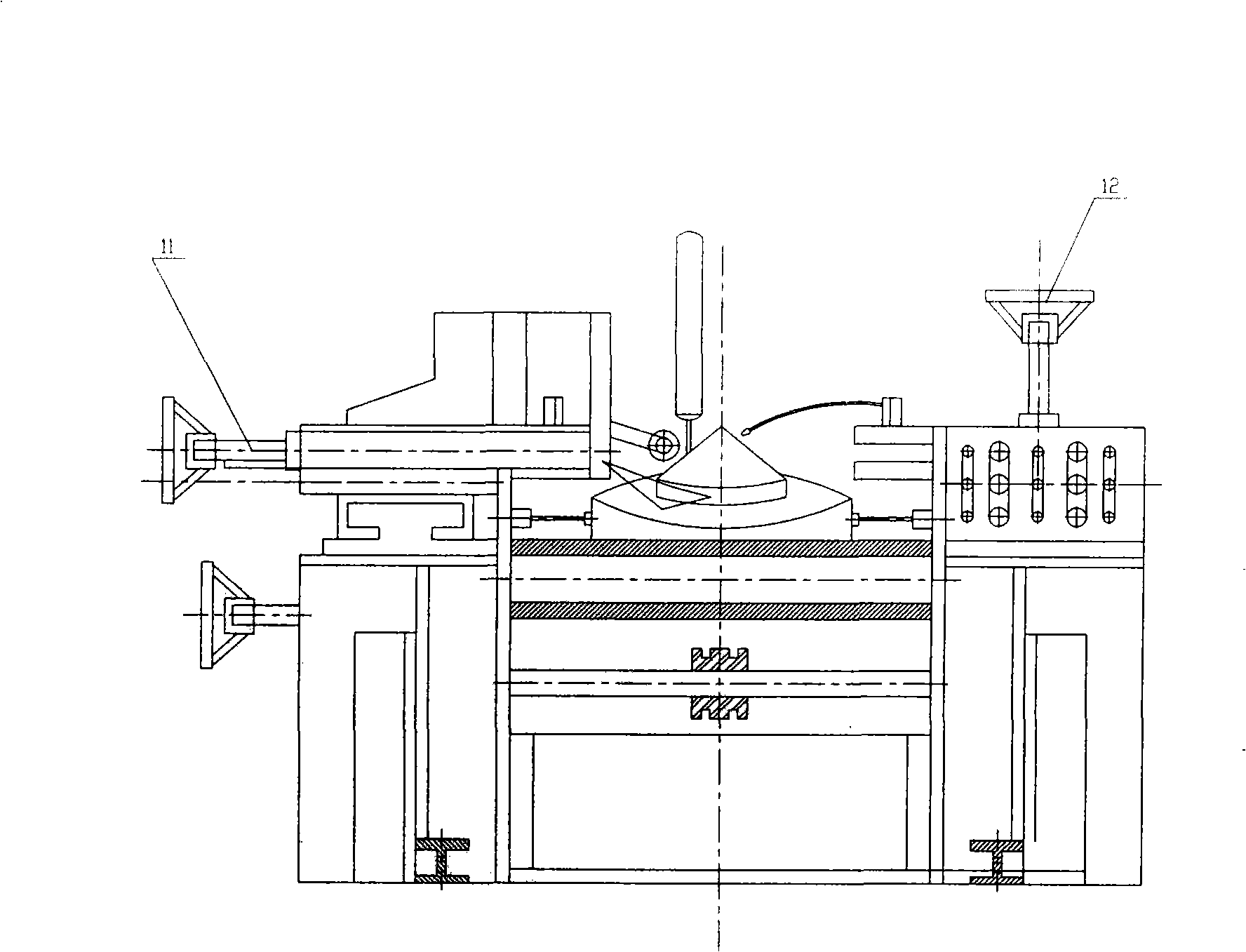

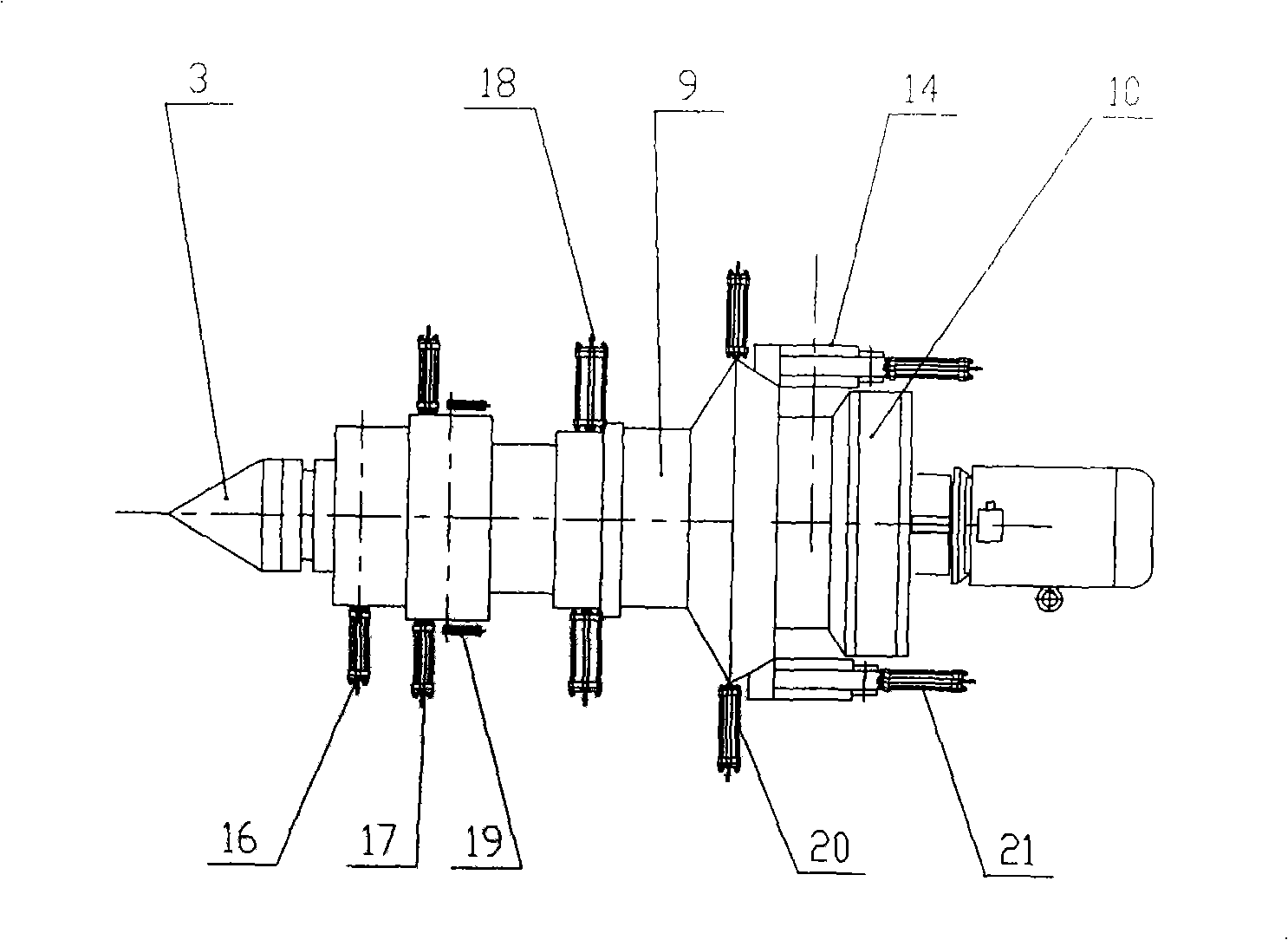

[0018] Referring to the accompanying drawings, the spiral blade rolling mill includes a frame 1 symmetrically arranged at both ends. The frame 1 is welded by H steel and angle steel to form a frame, supplemented by steel plates, and a fixed shaft 4 is horizontally arranged at both ends of the frame 1. 4 The supporting seat 5 is symmetrically hinged in the middle part, and the lower end of the supporting seat 5 is provided with an angle adjustment device. The angle adjusting device includes a floating shaft 14 inserted in the lower end of the supporting seat 5. In the installation hole of the floating shaft on the top, the axial ends of the floating shaft 14 are limited, and the lower end of the support seat 5 is hinged with a roll angle adjustment oil cylinder 13, and the other end of the roll angle adjustment oil cylinder 13 is hinged at the bottom of the frame 1. The angle adjustment oil cylinder 13 drives the support seat 5 to rotate around the fixed shaft 4, thereby driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com