Manufacturing process of ceramic tiles and special equipment for the process

A manufacturing process, a technology for ceramic tiles, applied in manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of sluggish flat patterns, gloss differences, lack of three-dimensional feeling, etc. Strong form, easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0029] In this embodiment, the ceramic tiles that produce a natural aurora effect pattern on the surface are made of the following raw materials in weight percentage:

[0030] Porcelain sand 59%~80% black, white clay 15%~40%, additive 0.5%~5%

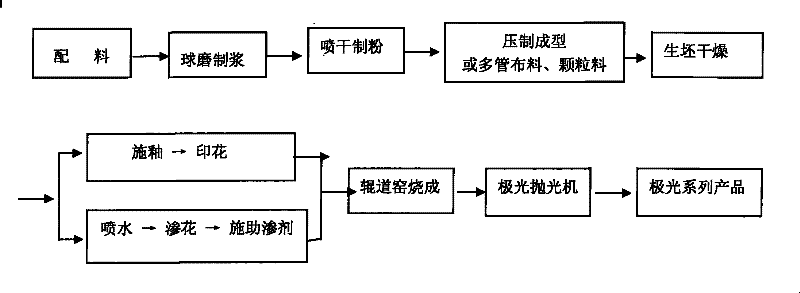

[0031] see figure 1 As shown, the manufacturing process of the said surface to produce the patterned tiles resembling the natural aurora effect includes:

[0032] (1) Powder preparation;

[0033] (2) Single-tube fabric, multi-tube fabric, and granular material are pressed and formed;

[0034] (3) The green body is dried and the surface is decorated;

[0035] (4) Roller kiln firing;

[0036] (5) Perform light difference polishing treatment on the surface of the fired finished bricks to form a light pattern resembling the natural aurora effect.

[0037] Described (1) powder material preparation process further comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com