Snubbing serving device of combined type hydraulic oil-water well

An operating device and combined technology, applied in wellbore/well components, earthmoving, sealing/packing, etc., can solve the problems of polluted strata, blowout, oil well crushed and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

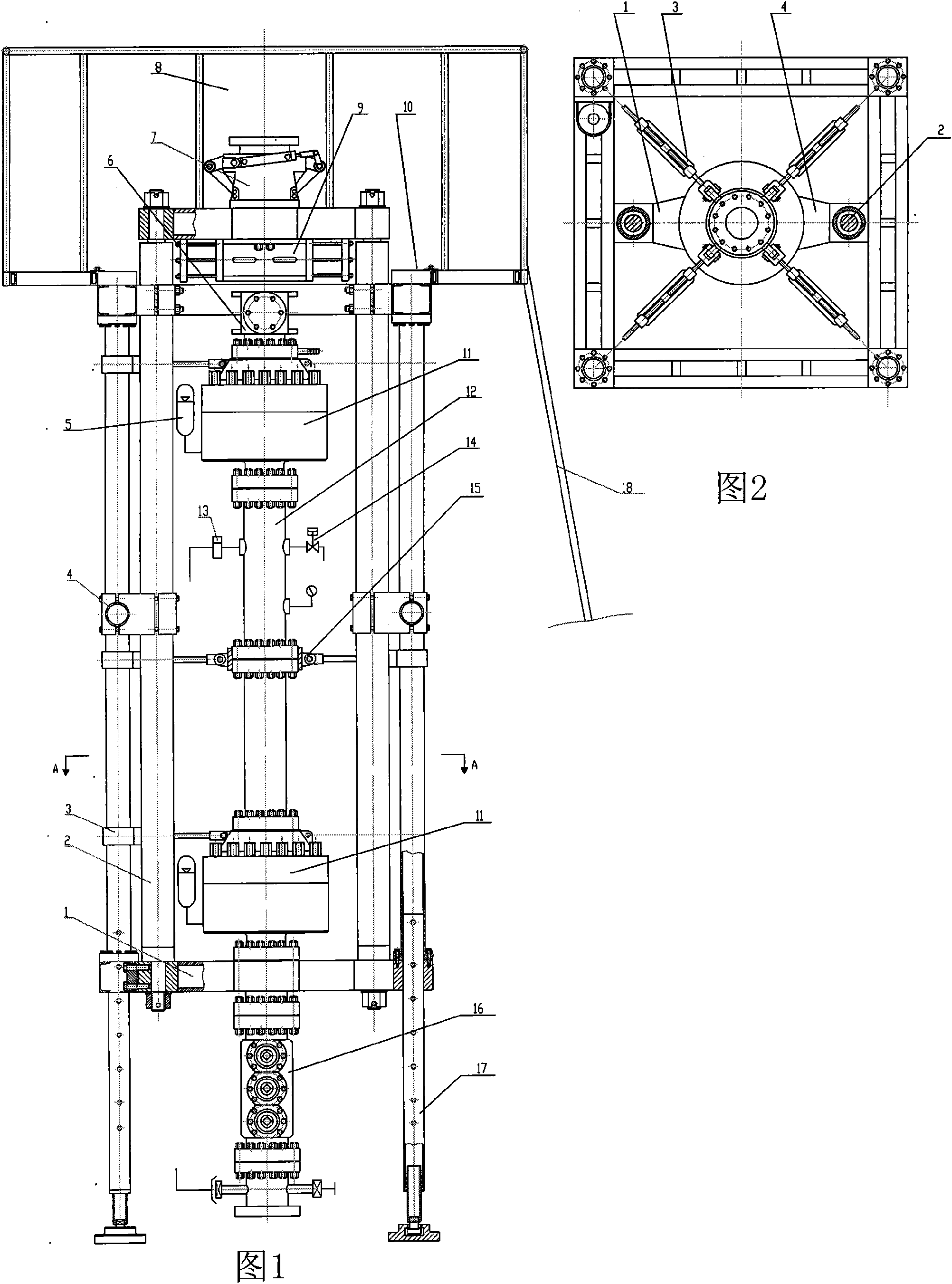

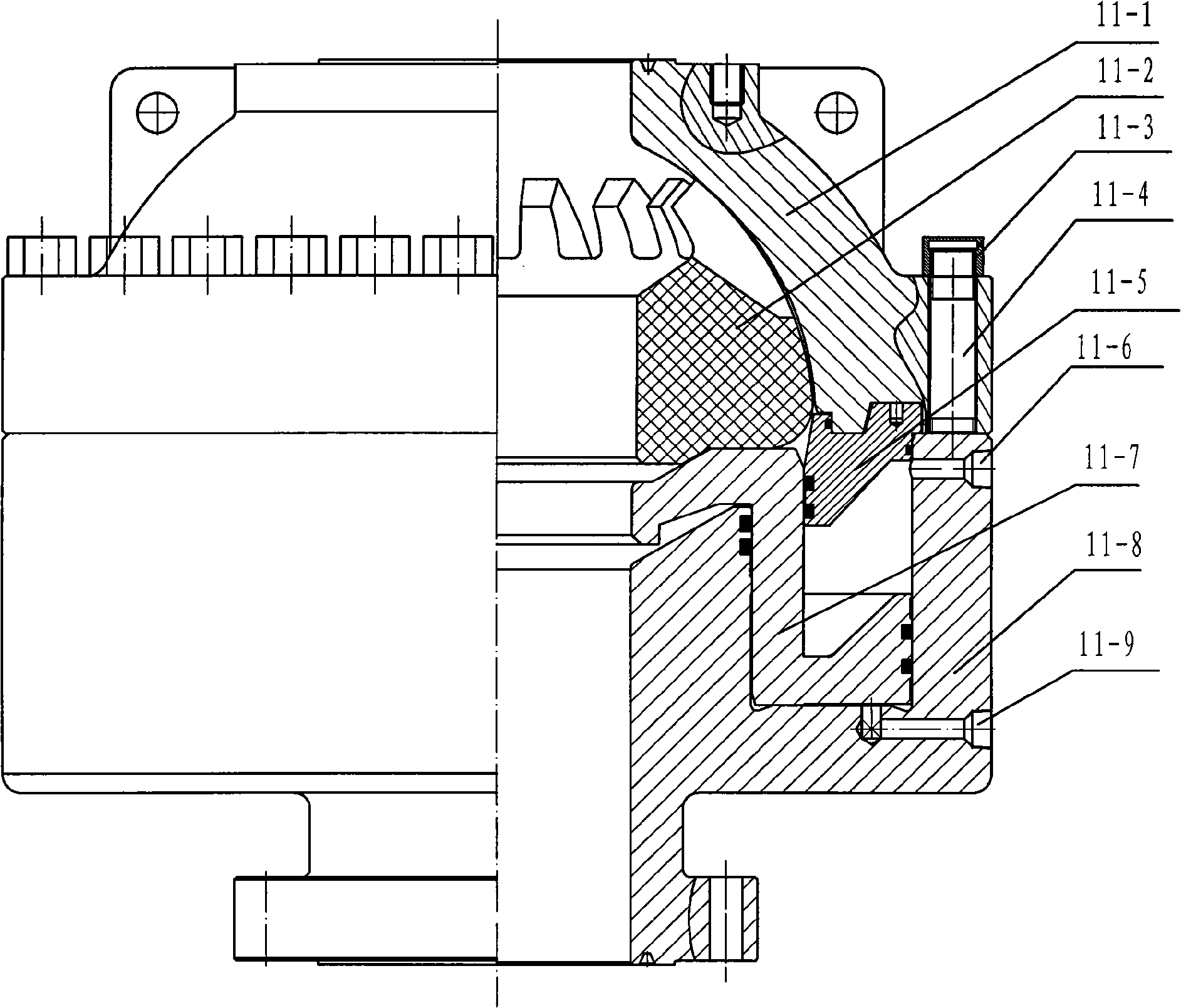

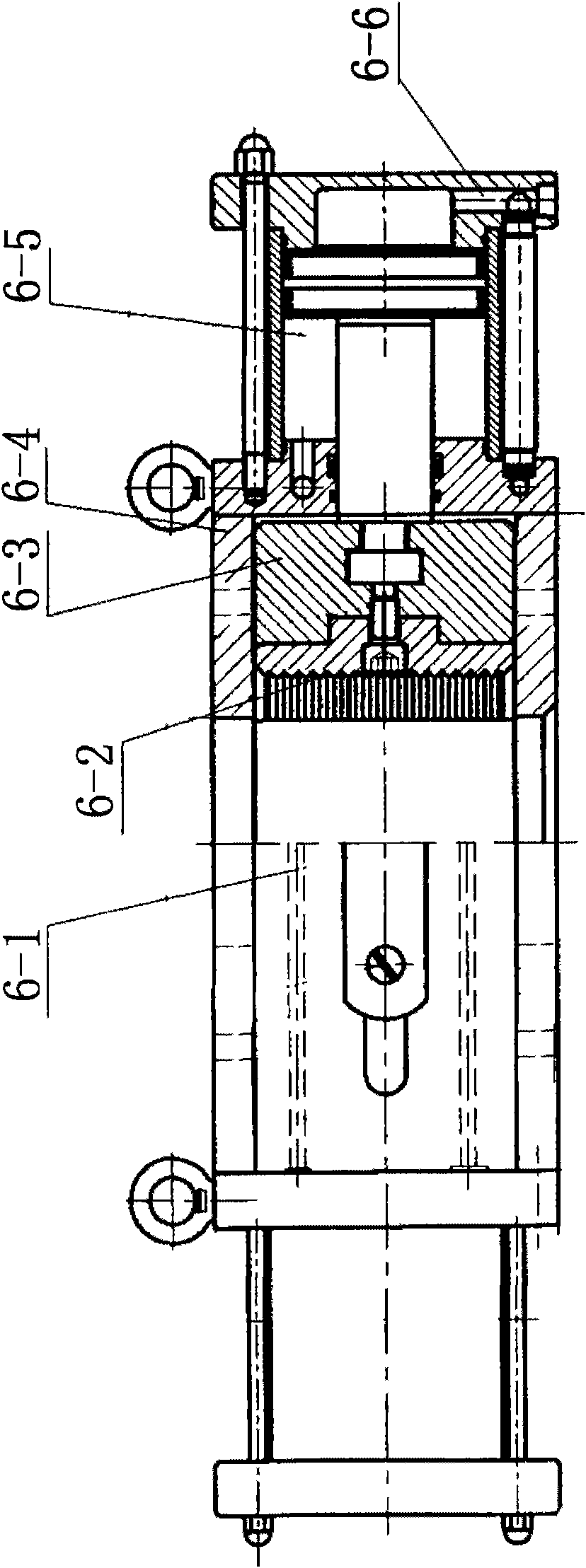

[0025] The present invention consists of a hydraulic three-gate blowout preventer 16, an annular blowout preventer 11, an energy storage package 5, a lifting cross 12, a hydraulic balance valve 13, a hydraulic pressure relief valve 14, a fixed anti-top slip 6, Swimming anti-top slips 9, self-tightening hydraulic slips 8, rectangular stand 17, oil cylinder 2, ring-shaped operating platform 10, lifting beam 7 and ladder 18, characterized in that the hydraulic three-ram BOP inlet It is flange-connected with the large cross of the oil well, and the outlet is connected with the inlet of the first annular BOP through the flange nipple, and the outlet of the first annular BOP is connected with the lower end flange of the rising cross through the flange nipple. The upper end of the high cross i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com