Biomass semi-gasification furnace

A semi-gasification, biomass technology, applied in climate change adaptation, household stoves/stoves, production of combustible gases, etc. The effect of simple structure, low emission and high-efficiency emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

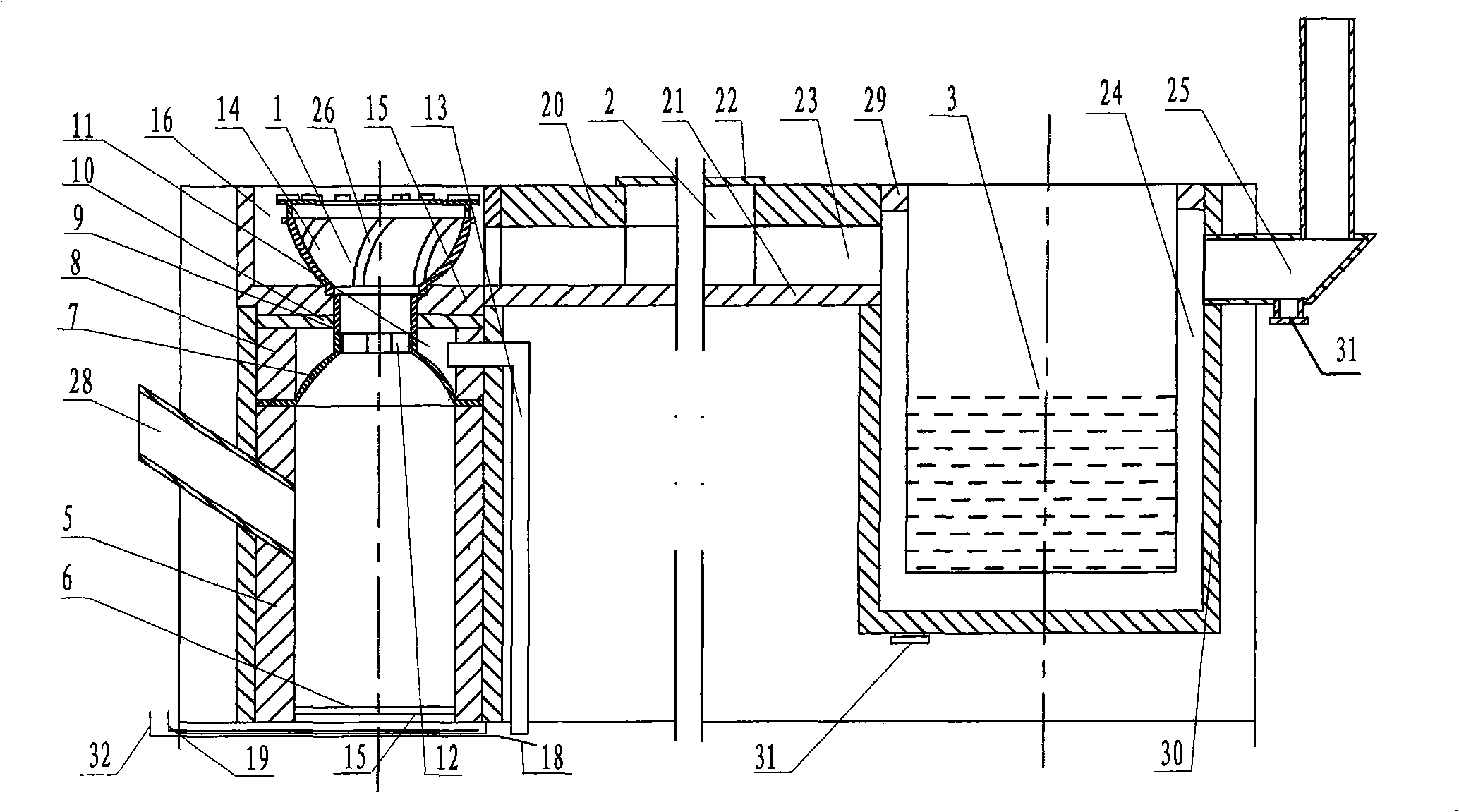

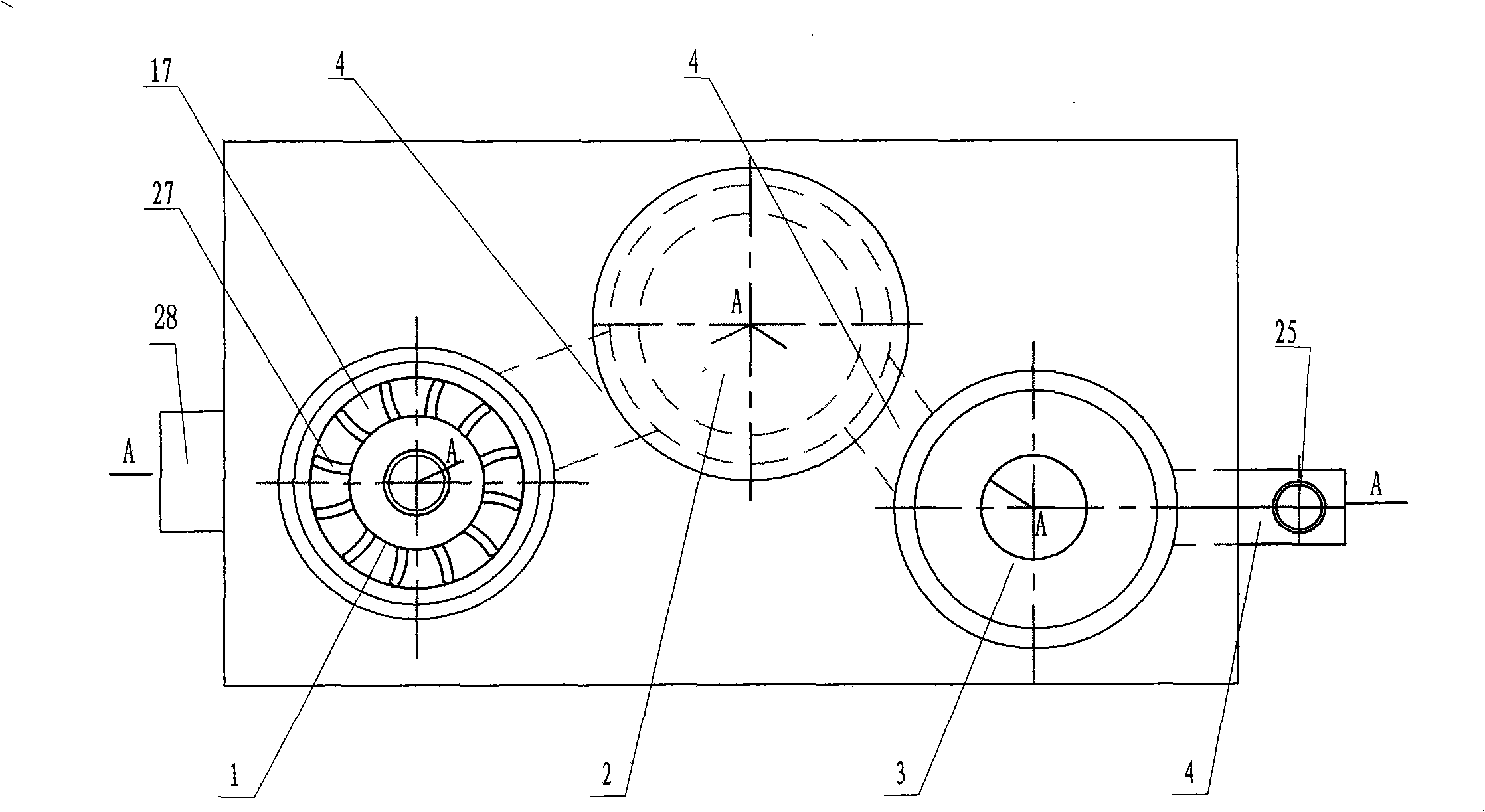

[0024] by attached figure 1 , figure 2 As shown, a biomass semi-gasification furnace includes a main furnace 1 arranged on the left side of the furnace body, an auxiliary furnace 2 in the middle, a hot water bucket 3 on the right side, and an exhaust passage 4 communicating with them; the main furnace 1 Including the furnace core 5 arranged on the bottom plate of the furnace body, the lower part of the inner cavity of the furnace core 5 is provided with a furnace bridge 6, the top of the furnace core 5 is connected to the fire collection cover 7, and forms a furnace with the charging port 28, and the upper side wall of the fire collection cover 7 There are several oxygen supply grooves 12 on the top, an oxygen supply jacket 8 is arranged on the outside of the fire collection cover, the top of the fire collection cover is connected to the oxygen supply inner sleeve 9, and an oxygen supply partition 10 is nested in the upper part of the oxygen supply inner cover 9, and the oxyg...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap